Injection type two-component epoxy pultrusion glue-injection system

A two-component, epoxy pultrusion technology, applied in the field of pultrusion, can solve the problems of low equipment requirements, unstable control, poor product strength, etc., and achieve the effects of improving process performance, stable liquid delivery, and avoiding color difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

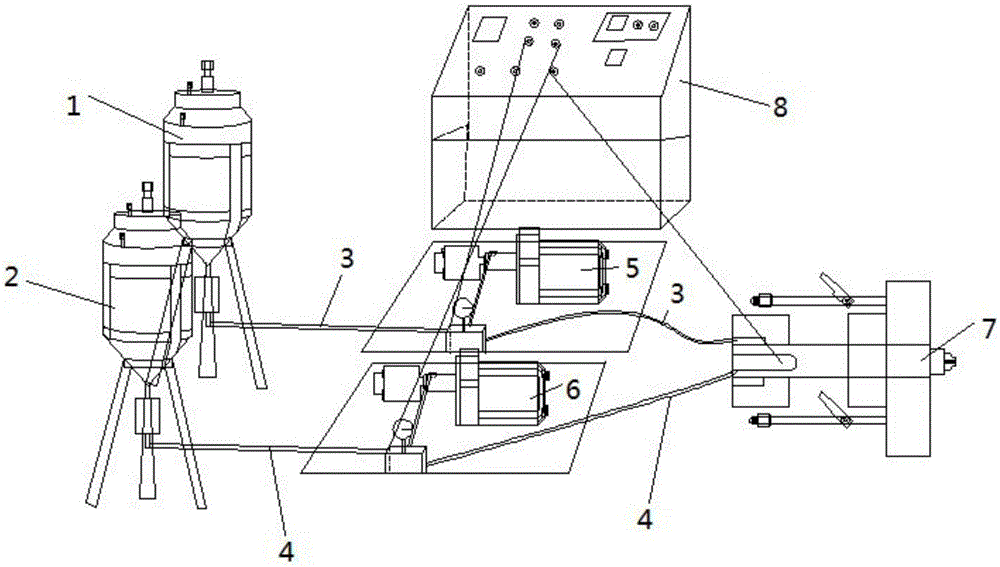

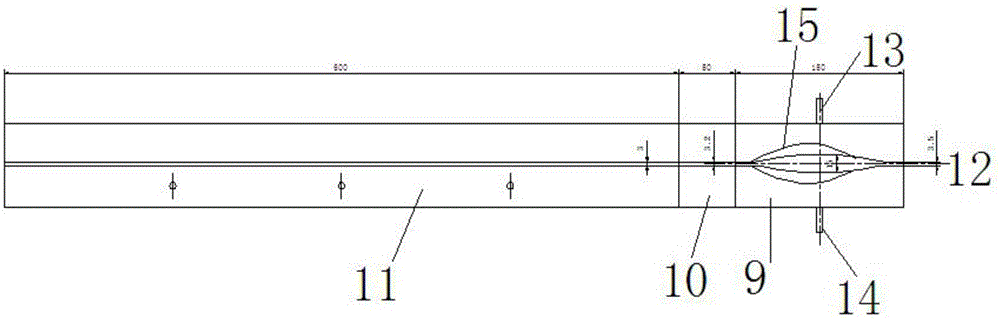

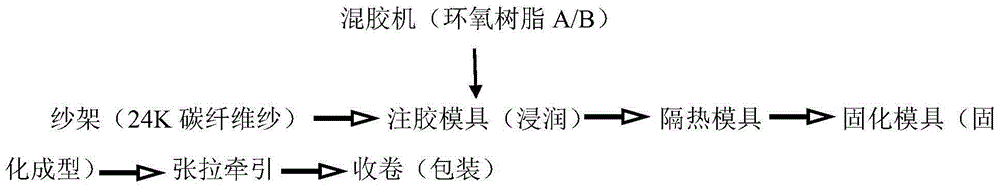

[0040] As shown in the figure, an injection-type two-component epoxy pultrusion injection system includes sequentially connected epoxy resin injection machines, injection molds, heat insulation molds and curing molds;

[0041] Among them, the epoxy resin injection machine includes a first storage tank, a second storage tank, a first gear metering pump, a second gear metering pump, a dynamic mixing gun, a first insulation pipeline, a second insulation pipeline, a digital a display device, a first frequency converter, a second frequency converter and a base;

[0042] The first storage tank and the second storage tank are merged into the dynamic mixing gun through the first heat preservation pipeline and the second heat preservation pipeline respectively;

[0043] The first gear metering pump and the second gear metering pump are respectively connected to the first heat preservation pipeline and the second heat preservation pipeline, the first gear metering pump controls the flow...

Embodiment 2

[0058] It is basically the same as Example 1, the difference is:

[0059] The injection type two-component epoxy pultrusion glue injection system also includes a first material lifting pump and a second material lifting pump, and pressure sensors are installed in the first material lifting pump and the second material lifting pump (the pressure sensor can sense The hydraulic pressure in the component A / B storage tank changes. When the liquid level of component A or B is lower than a certain value, the pressure sensor will sense the change and start the pump to feed the storage tank; when When the hydraulic pressure value is higher than a certain value, feeding will be stopped; the maximum and minimum pressure values can be pre-set according to needs), the first material lifting pump is electrically connected to the first material storage tank, the second material lifting pump is connected to the second storage tank Tank electrical connection;

[0060] When in use, put the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com