Machining method of wave spring

A wave spring and processing method technology, applied in the field of spring manufacturing, can solve the problems of easily causing cracks, unable to meet the requirements of drawings, difficult to maintain the shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

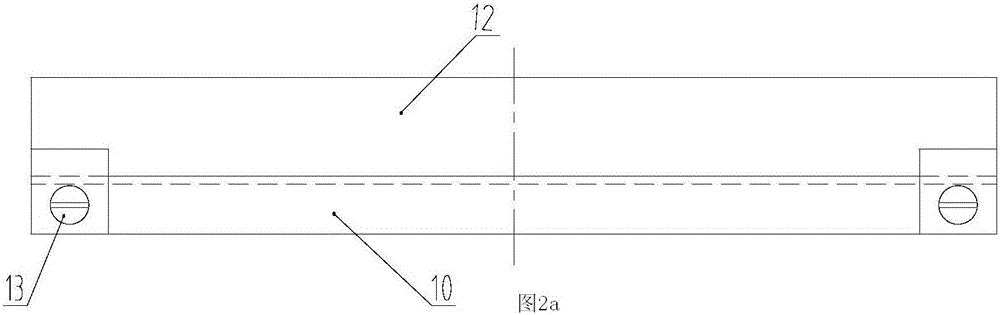

Examples

Embodiment 1

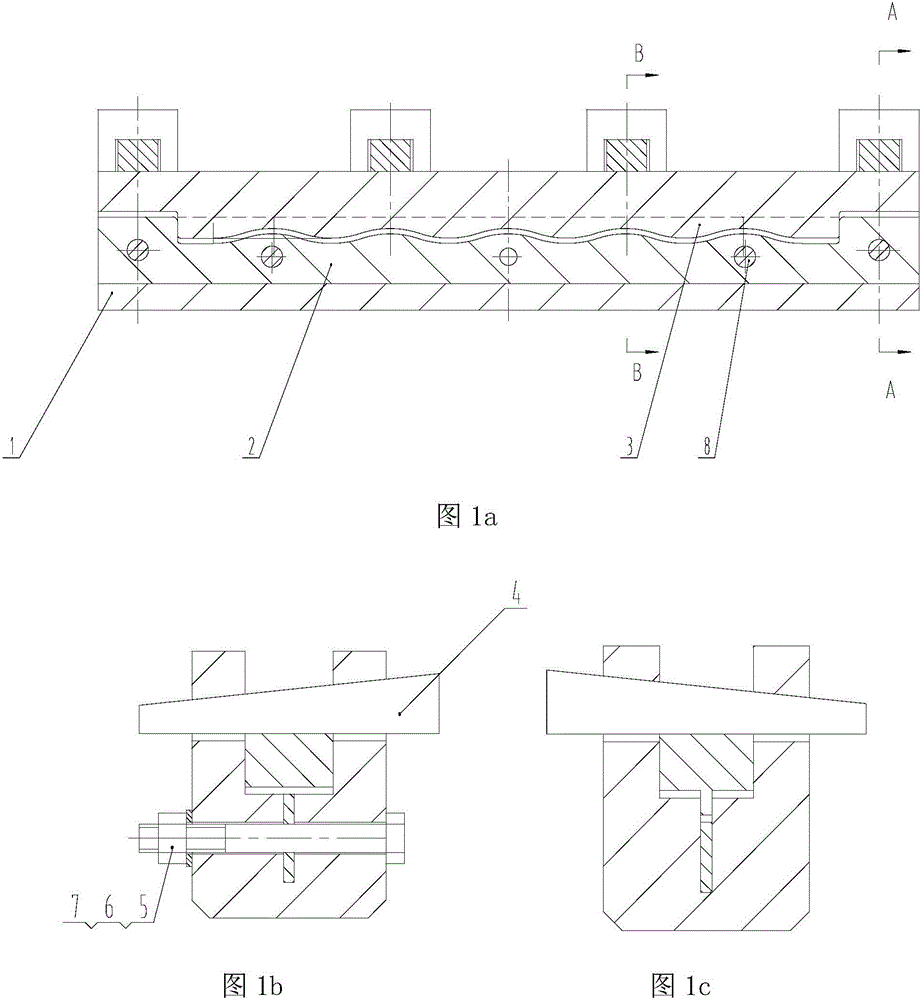

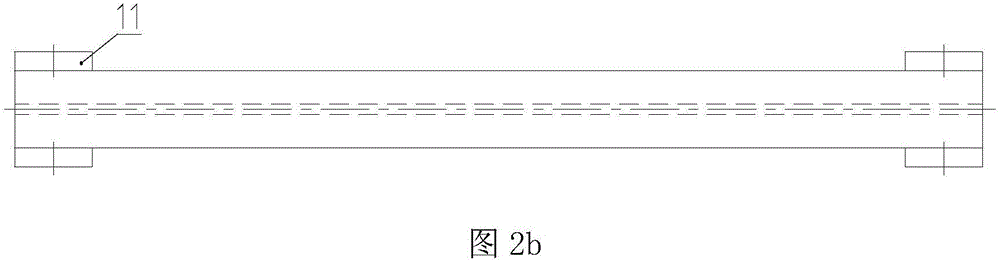

[0042] Example 1: The spring expansion of the treatment is 249×1.9mm.

[0043] Clean the parts and tooling with acetone, and dry them. Put one wave spring blank into the molding tooling for vacuum aging treatment:

[0044] 1.1. Insert 2 load thermocouples into the holes of the tooling where the thermocouples are placed. When the temperature rises, record the heat treatment holding time when the indicated value of the last load thermocouple reaches the lower limit of the set temperature.

[0045]1.2. Close the furnace door and vacuumize the furnace to make the pressure in the furnace lower than 6.65×10-2Pa;

[0046] 1.3. Heating, heat preservation and cooling, raise the furnace temperature to 600°C at 10°C / min, keep warm until the part temperature reaches 600°C, and raise the furnace temperature to 800±10°C at 6°C / min, at 800±10 ℃ heat preservation for 1 hour + 10 minutes; cooling, first vacuum cool the parts to 650±10 ℃, then turn on the argon gas and fan to cool the parts be...

Embodiment 2

[0051] Example 2: The spring expansion of the treatment is 249×1.9mm.

[0052] Clean the parts and tooling with acetone, and dry them. Put 2 wave spring blanks into the molding tooling at the same time, and carry out vacuum aging treatment:

[0053] 2.1. Insert 3 load thermocouples into the holes of the tooling where the thermocouples are placed. When the temperature rises, record the heat treatment holding time when the indicated value of the last load thermocouple reaches the lower limit of the set temperature.

[0054] 2.2. Close the furnace door and vacuumize the furnace to make the pressure in the furnace lower than 6.65×10-2Pa;

[0055] 2.3. Heating, heat preservation and cooling, raise the furnace temperature to 600°C at 10°C / min, keep warm until the temperature of the parts reaches 600°C, and raise the furnace temperature to 800±10°C at 6°C / min, at 800±10°C ℃ heat preservation for 1 hour + 10 minutes; cooling, first vacuum cool the parts to 650±10 ℃, then turn on the ...

Embodiment 3

[0060] Example 3: The spring expansion of the treatment is 249×2.5mm.

[0061] Clean the parts and tooling with acetone, and dry them. Put one wave spring blank into the forming tooling at the same time, and carry out vacuum aging treatment:

[0062] 3.1. Insert two load thermocouples into the holes of the tooling where the thermocouples are placed. When the temperature rises, record the heat treatment holding time when the indicated value of the last load thermocouple reaches the lower limit of the set temperature.

[0063] 3.2. Lock the furnace door and vacuumize the furnace to make the pressure in the furnace lower than 6.65×10-2Pa;

[0064] Cleaning: Clean the parts and tooling with acetone and dry them.

[0065] 3.3. Heating, heat preservation and cooling, raise the furnace temperature to 600°C at 10°C / min, keep warm until the temperature of the parts reaches 600°C, and raise the furnace temperature to 800±10°C at 6°C / min, at 800±10 ℃ heat preservation for 1 hour + 10 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com