Continuous mold for manufacturing vehicle partition boards, and continuous manufacturing method

A partition and mold technology, applied in the field of machinery, can solve the problems of troublesome operation, manpower, complicated equipment, and high equipment cost, and achieve the effects of small production error, improved production quality, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

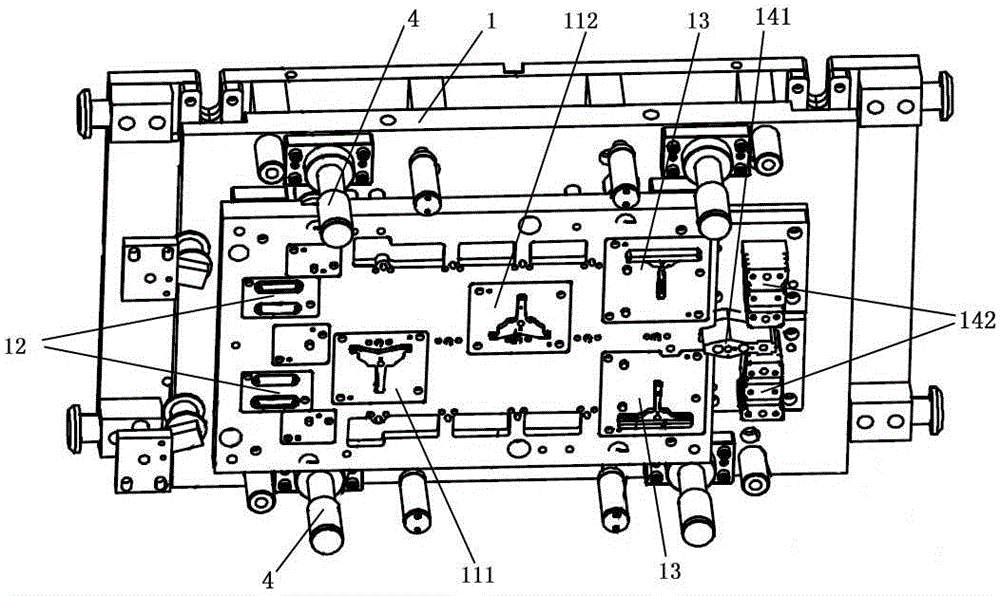

[0035] Such as Figure 1-5 As shown, the continuous mold for the manufacture of the vehicle partition provided in this embodiment includes an upper mold 1 and a lower mold 2, and the lower mold 2 and the upper mold 1 are respectively provided with a guide platform 3 and a guide column 4 corresponding to each other; Die 1 is provided with notch knife group, forming punch 12, trimming knife 13, cuts off and bends punch; Described forming punch 12 is provided with two sets, is mirror image distribution on the both sides of upper mold 1 transverse direction mutually; The edge trimming knife 13 described is provided with two sets, is mutually mirror image distribution on the both sides of upper mold 1 transverse; Side die 23, cutting and bending die;

[0036] The incision knife group is arranged behind the forming punch 12, and includes incision knife I 111 and incision knife II 112. The incision knife I 111 and incision knife II 112 are mirror images of each other in shape, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com