Backswing automatic washing and filtering device

A filter device and automatic flushing technology, which is applied in the direction of filtration separation, fixed filter element filter, chemical instrument and method, etc., can solve the problems of reduced speed and weakened sewage treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

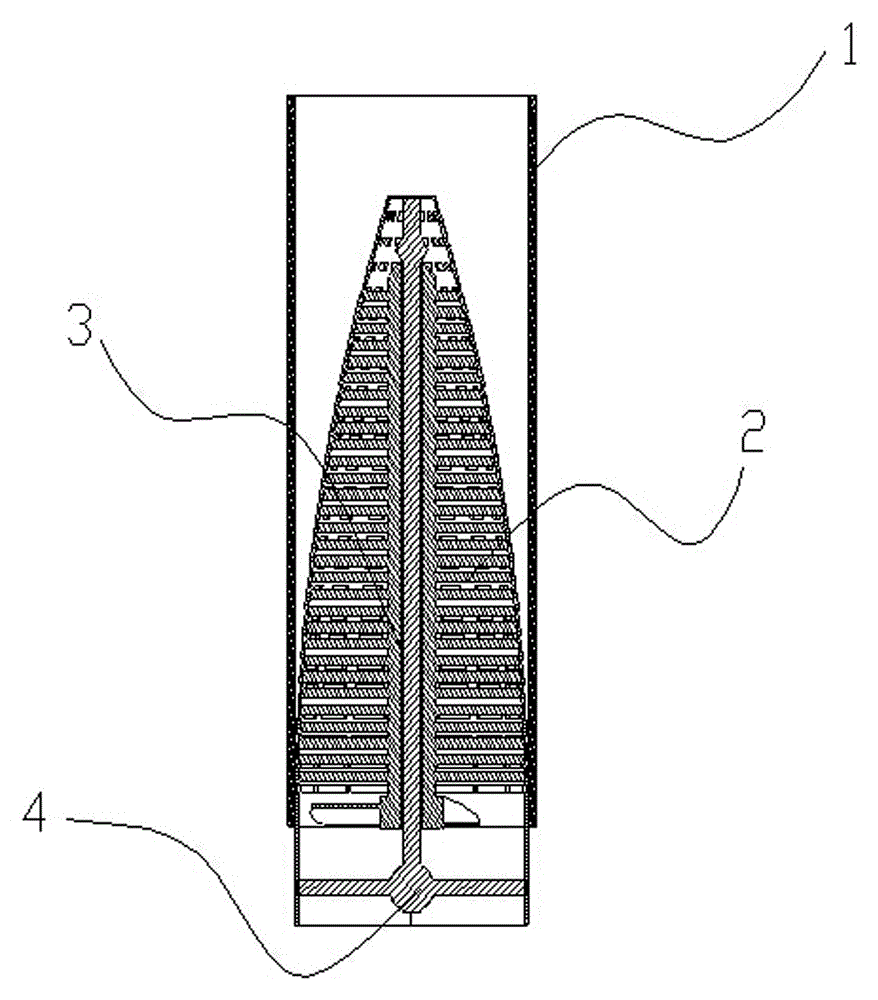

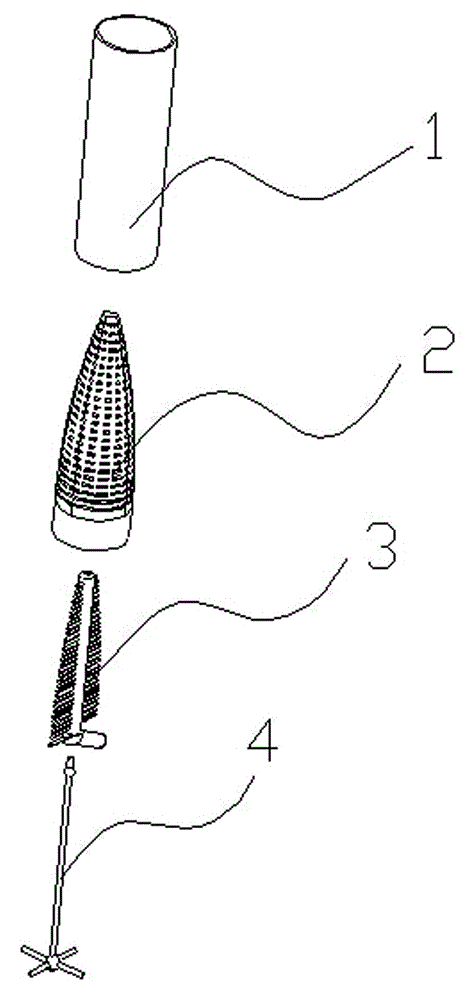

[0012] See attached figure 1 , 2 , the present invention is made up of water pipe 1, filter screen tube 2, belt brush impeller 3 and fixed frame 4, and band brush impeller 3 is rotatably sleeved on the fixed frame 4, and one end of fixed frame 4 is fixedly connected with filter screen tube 2, and another One end is fixed to the other end of the filter screen cylinder 2 through the support frame on the fixing frame 4, and the filter screen cylinder 2 is filled in the water pipe 1.

[0013] The filter screen cylinder 2 is conical with one end open and the other end closed.

[0014] The brushed impeller 3 is installed at one end close to the support frame on the fixed frame 4 .

[0015] The sheet shape of the brushed impeller 3 is opposite to the inflow direction of sewage.

[0016] The cleaning brush and the inner wall of the filter cylinder 2 are modeled.

[0017] When applying the present invention, the water pipe 1 is fixed at the entrance of the sewage to be treated, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com