A kind of salt-free chicken paste essence and preparation method thereof

A chicken paste and essence technology, applied in the field of food processing, can solve problems such as high cost, unfavorable health, health threat, etc., and achieve the effect of solving the problem of quality preservation and inhibiting the generation and reproduction of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

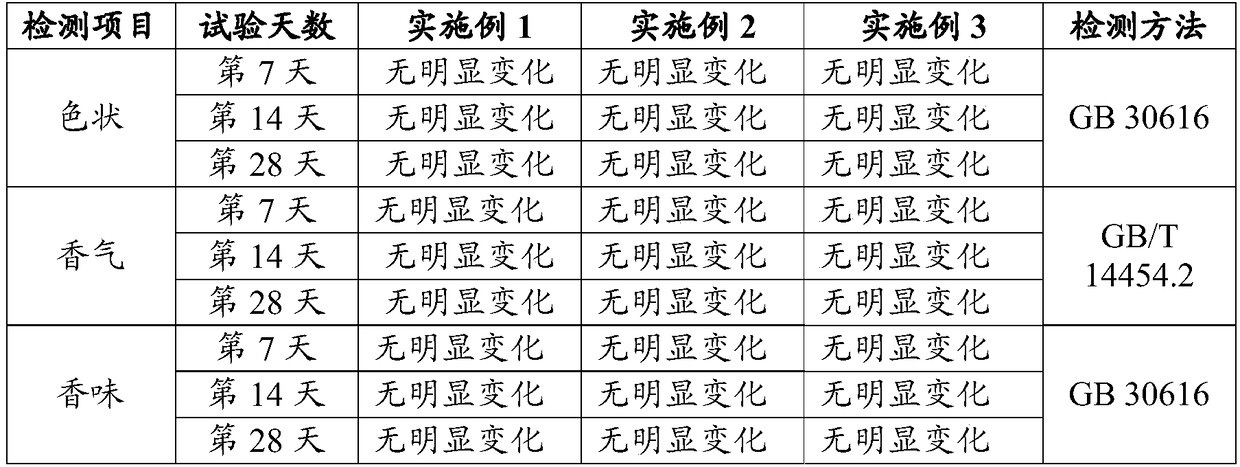

Examples

preparation example Construction

[0025] The invention provides a salt-free chicken paste essence and a preparation method thereof, specifically, the preparation method of the salt-free chicken paste essence comprises the following steps:

[0026] A preparation method of salt-free chicken paste essence, comprising the following steps:

[0027] 1) Enzymatic hydrolysis: Take 25-35 parts of chicken breast meat and 25-30 parts of chicken skeleton, wash and chop them, crush them in a bone mud machine, add 40-50 parts of water, boil for 1 hour, and grind them to get colloidal chicken juice; Adding 0.08-0.12 parts of alkaline protease, 0.04-0.07 parts of flavor protease and 0.02-0.08 parts of neutral protease to the colloidal chicken broth for enzymolysis, after enzymolysis, the enzyme is inactivated, and the chicken broth is obtained by filtering;

[0028] In this step, the method of boiling combined with enzymatic hydrolysis is adopted. During the boiling process, the protein and other nutrients in the chicken and ...

Embodiment 1

[0036] A preparation method of salt-free chicken paste essence, comprising the following steps:

[0037] 1) Enzymatic hydrolysis: take 30 parts of chicken breast meat and 28 parts of chicken skeleton, wash and chop them, crush them with a bone mud machine, add 45 parts of water, boil for 1 hour, and grind them with colloids to get colloidal chicken juice; add them to the colloidal chicken juice 0.1 part of alkaline protease, 0.05 part of flavor protease and 0.05 part of neutral protease were enzymatically hydrolyzed at 55°C, after enzymolysis, the enzyme was extinguished at 90°C for 10 minutes, and chicken broth was obtained by filtering through a 40-mesh sieve;

[0038] 2) Reaction: Take 45 parts of chicken broth prepared in step 1), add Maillard reaction accelerator, 10 parts of water, and 10 parts of chicken oil, and perform Maillard reaction at 98° C. After the reaction, the chicken reactant is obtained;

[0039] The Maillard reaction promoter includes 1.8 parts of L-cyste...

Embodiment 2

[0042] A preparation method of salt-free chicken paste essence, comprising the following steps:

[0043] 1) Enzymatic hydrolysis: Take 25 parts of chicken breast meat and 30 parts of chicken skeleton, wash and chop them, crush them with a bone mud machine, add 40 parts of water, boil for 1 hour, and grind them with colloids to get colloidal chicken juice; add them to the colloidal chicken juice 0.08 parts of alkaline protease, after 3 hours of enzymolysis at 55°C, add 0.07 parts of flavor protease and 0.02 parts of neutral protease and continue enzymolysis at 55°C for 3 hours, after enzymolysis, inactivate the enzyme at 90°C for 15 minutes, and filter to obtain chicken broth;

[0044] 2) Reaction: Take 50 parts of chicken broth prepared in step 1), add Maillard reaction accelerator, 15 parts of water, and 12 parts of chicken oil, and perform Maillard reaction at 98° C. After the reaction, the chicken reactant is obtained;

[0045] The Maillard reaction promoter includes 2 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com