Method of two-step united multi-strain fermented feed

A combined fermentation and multi-strain technology, applied in animal feed, animal feed, application, etc., can solve the problems of low total number of probiotic colonies, limited growth of aerobic bacteria, and insignificant increase in protein content, etc., to achieve good growth and reproduction, The effect of increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

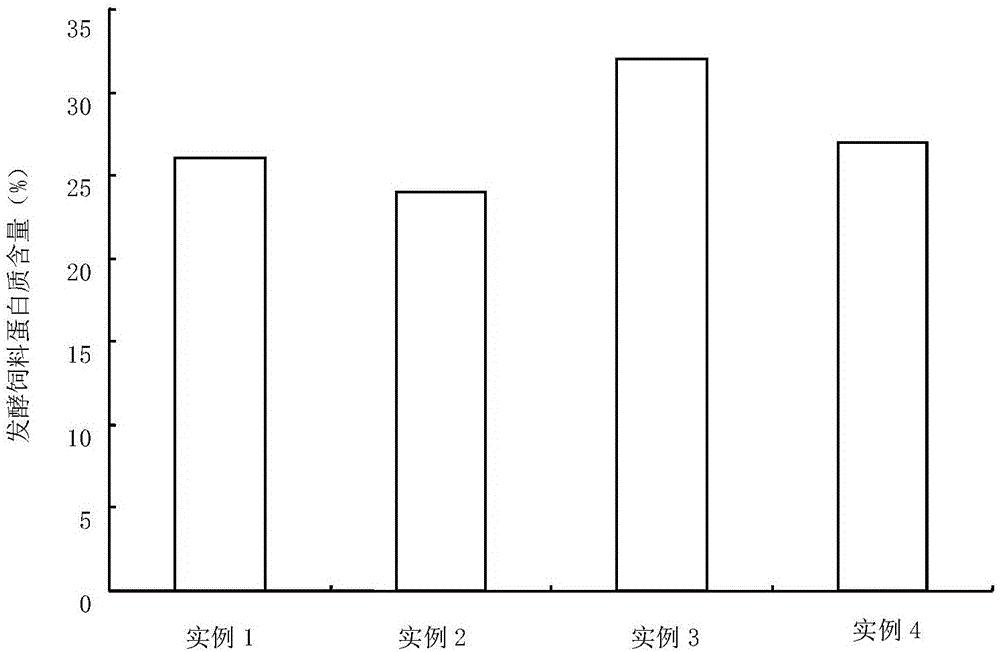

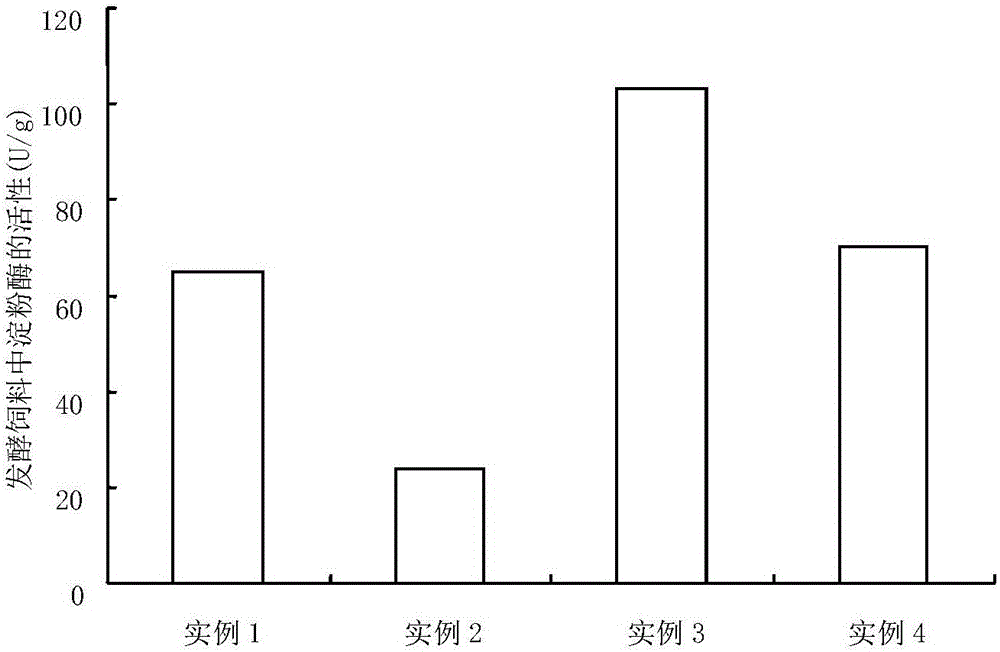

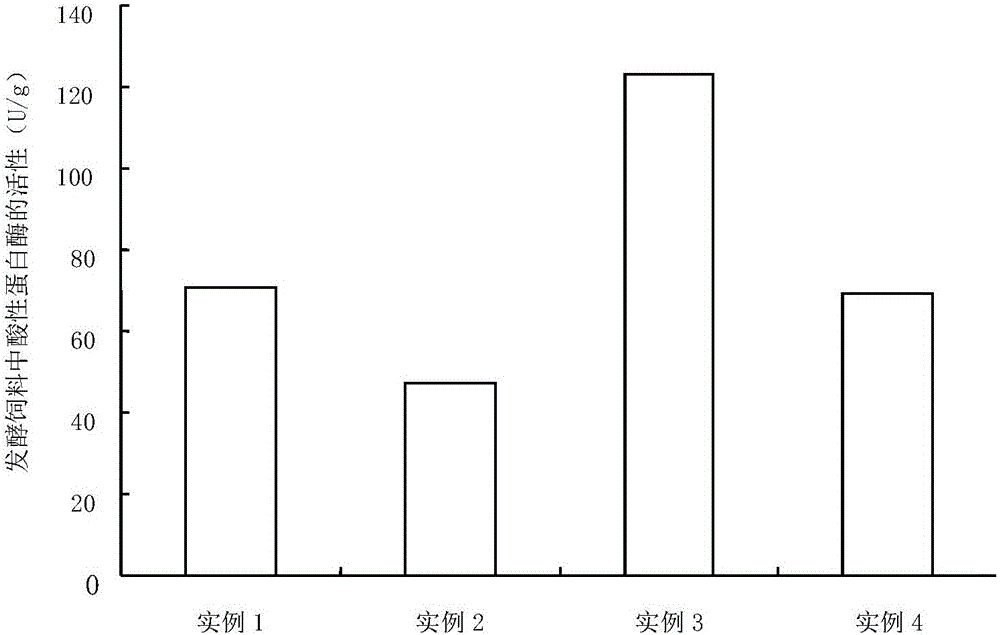

[0041] Embodiment 1 two strains aerobic, anaerobic two-step fermented feed

[0042] The specific implementation steps are as follows:

[0043] A. Cultivation of seeds

[0044] a. Preparation of pure culture of Bacillus subtilis seeds: transfer the activated Bacillus subtilis liquid culture solution to LB seed culture solution, and culture at a constant temperature of 37° C. for 10 to 18 hours with shaking.

[0045] b. Preparation of pure culture of Lactobacillus plantarum seeds: transfer activated Lactobacillus plantarum liquid culture solution to MRS seed culture

[0046] Nutrient solution, culture at 37°C for 10-18 hours.

[0047] B. Crushing of fermentation raw materials

[0048] Take 10-15 parts of corn, 10-15 parts of bran, 15-25 parts of soybean meal, 35-45 parts of palm meal, 10-15 parts of subflour, 1-2 parts of urea, 0.5-1 part of glucose, mix and grind , sieved, the fineness is 20-40 mesh.

[0049] D. Mixing water for fermentation raw materials

[0050] The rat...

Embodiment 2

[0056] Embodiment 2 multi-strain anaerobic fermentation feed

[0057] The specific implementation steps are as follows:

[0058] A. Preparation of Seed Solution

[0059] a. Preparation of pure culture of Bacillus subtilis seeds: transfer 1ml to 2ml of activated Bacillus subtilis liquid culture solution to 50ml LB seed culture solution, and culture at a constant temperature of 37°C for 10 to 18 hours.

[0060] b. Preparation of pure culture of Lactobacillus plantarum seeds: transfer 1ml-2ml of activated Lactobacillus plantarum liquid culture solution to 50ml MRS seed culture solution, and culture at 37°C for 10-18 hours.

[0061] c. Preparation of pure culture of brewer's yeast seeds: transfer 1ml-2ml of activated brewer's yeast liquid culture solution to 50ml of YPD seed culture solution, and culture at 28-30° C. for 12-18 hours.

[0062] B. Crushing of fermentation raw materials

[0063] Take 10-15 parts of corn, 10-15 parts of bran, 15-25 parts of soybean meal, 35-45 part...

Embodiment 3

[0070] Embodiment 3 The method for making feed of the present invention

[0071] The specific implementation steps are as follows:

[0072] A. Activation of strains

[0073] a. Activation of Rhizopus: Pick the spores of Rhizopus from the slant of the test tube stored in the refrigerator at 0-4°C, inoculate them on the potato glucose slant test tube medium, cultivate them at a constant temperature of 28-30°C for 24-48 hours, and pick new bacteria The filaments were transferred to the potato glucose slant test tube culture medium, and cultured at a constant temperature of 28-30°C for 24-48h.

[0074] b. Activation of Aspergillus oryzae: Pick the spores of Aspergillus oryzae from the slant of the test tube stored in the refrigerator at 0-4°C, inoculate it on the potato glucose slant test tube medium, culture at a constant temperature of 28-30°C for 24-48 hours, and pick new bacteria The filaments were transferred to the potato glucose slant test tube culture medium, and culture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com