Plate type integral heat tube for heat radiation of electric magnetic iron remover

An electromagnetic iron remover and plate type technology, which is applied in the field of strengthening heat transfer, can solve the problems of poor heat dissipation effect, decreased heat dissipation performance of heat pipes, and uneven thickness of heat conduction plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

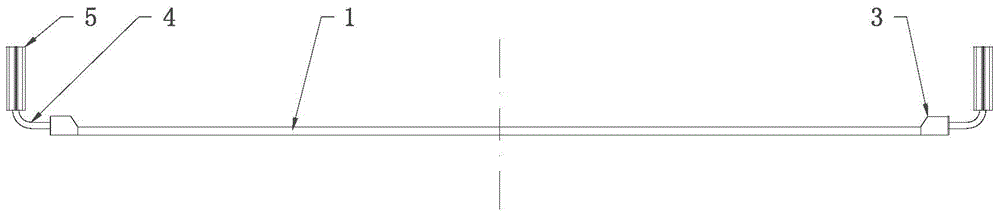

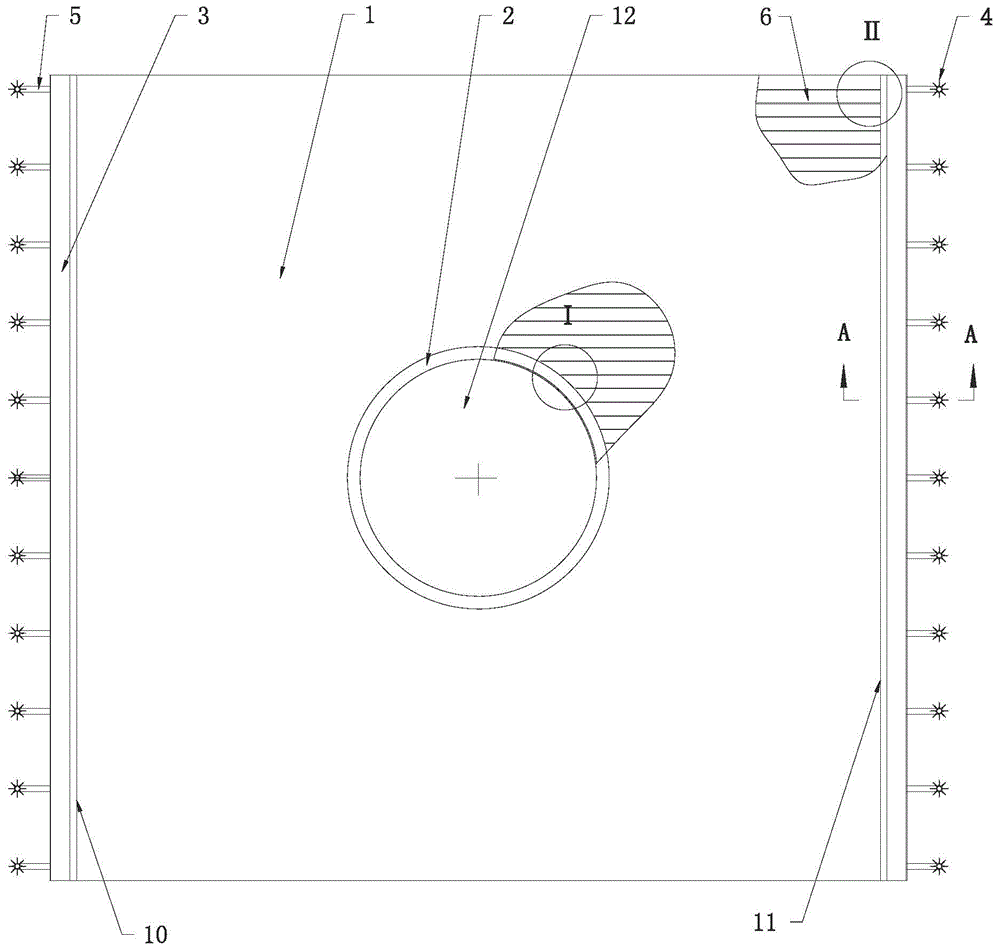

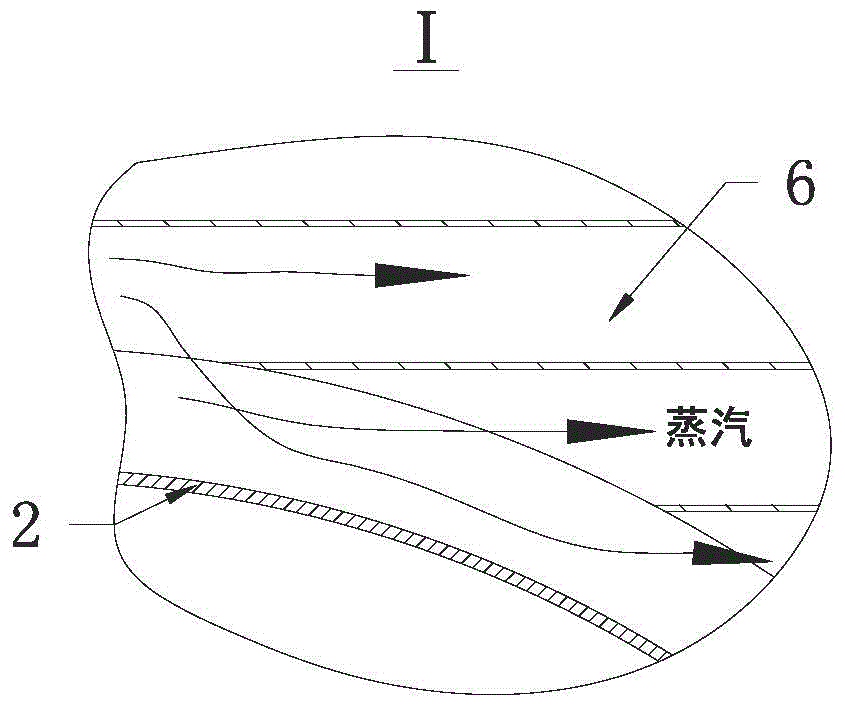

[0043] See attached figure 1 , 2 , 3, 4, 5, a plate-type integral heat pipe for heat dissipation of an electromagnetic iron remover, the plate-type integral heat pipe includes a rectangular flat plate 1, and evaporation channels 6 parallel to each other are evenly distributed on the rectangular flat plate 1, and the The evaporation channel 6 is located between the upper and lower surfaces of the rectangular flat plate 1, and its axis is parallel to the upper and lower surfaces of the rectangular flat plate 1; Extending and passing through the second side 11 parallel to the first side; a through hole 12 is provided in the center of the rectangular flat plate 1, and the axis of the through hole 12 is perpendicular to the upper and lower surfaces of the rectangular flat plate 1;

[0044] A hollow ring 2 is provided on the circumference of the through hole 12, and the evaporation channel 6 passing through the circumference of the through hole 12 communicates with the inner cavity...

Embodiment 2

[0059] See attached Figure 6 In this embodiment, the plate-type integral heat pipe is cut into two pieces through the center of the through hole 12 on the longitudinal section parallel or perpendicular to the axis of the evaporation channel 6, and each of the monomers has an evaporation channel port 13 An equalizing tube 7 is arranged on the section of the cutout, and one end of the equalizing tube 7 is closed, and the other end communicates with the hollow ring 2, and its side communicates with the port 13 of the evaporation channel passing through the section of the cutout.

[0060] In this embodiment, the thickness of the rectangular plate is 30mm;

[0061] In this embodiment, the cross-section of the evaporation channel or steam distribution pipe is square;

[0062] The cross-sectional area of the evaporation channel is 1200mm 2 ;

[0063] The cross-sectional area of the steam distribution pipe is 6 times the cross-sectional area of the evaporation channel;

[0...

Embodiment 3

[0071] See attached Figure 7 , in this embodiment, the plate-type integral heat pipe is cut into four individual pieces through the center of the through hole 12 on a longitudinal section parallel to or perpendicular to the axis of the evaporation channel 6, each of which has an evaporation channel port 13 An equalizing tube 7 is arranged on the section of the cutout, and one end of the equalizing tube 7 is closed, and the other end communicates with the hollow ring 2, and its side communicates with the port 13 of the evaporation channel passing through the section of the cutout.

[0072] In this embodiment, the thickness of the rectangular plate is 50mm;

[0073] In this embodiment, the cross-section of the evaporation channel or steam distribution pipe is rectangular;

[0074] The cross-sectional area of the evaporation channel is 2000mm 2 ;

[0075] The cross-sectional area of the steam distribution pipe is 9 times the cross-sectional area of the evaporation chann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com