Battery module

A battery module and battery technology, applied in battery pack components, secondary batteries, circuits, etc., can solve problems such as uneven temperature of battery modules, and achieve prevention of battery explosion, uniform internal temperature, cycle performance and service life. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

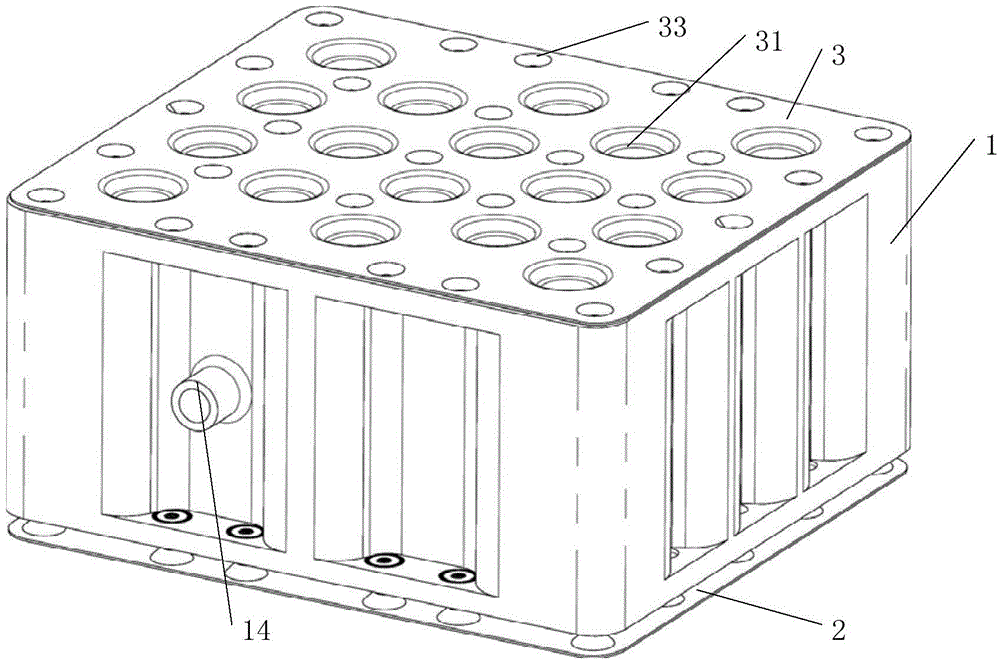

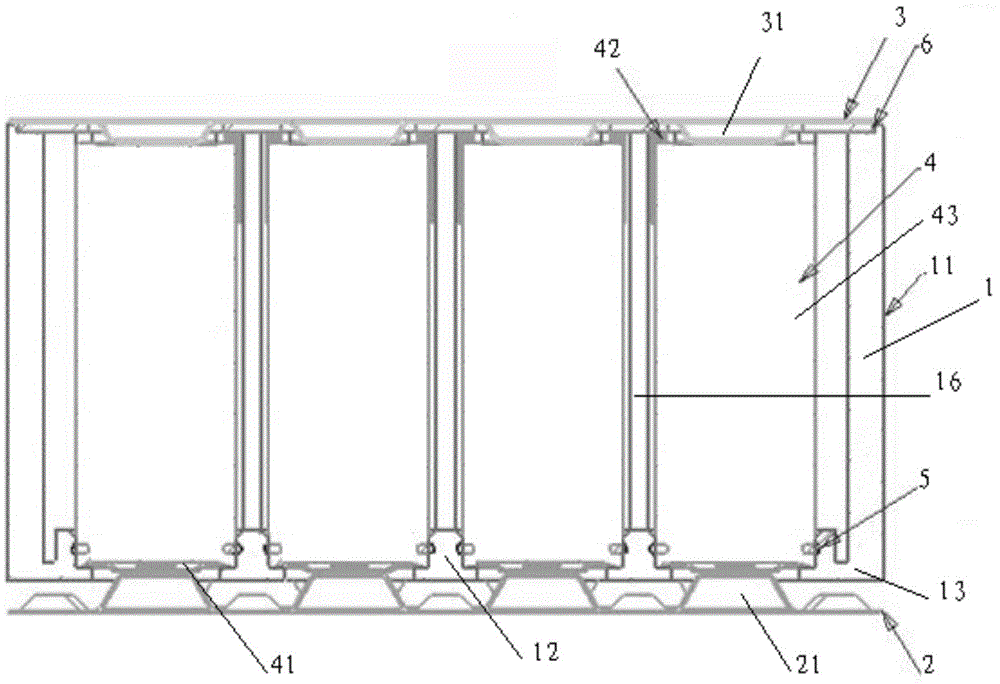

Embodiment 1

[0047] A cylindrical steel shell 26650 battery with CID (current interrupt device, current cut-off device), VENT (pressure relief valve) and pressure relief hole structure is used as the battery for assembly, 18 of which form a parallel battery module, and 100 of them are connected in parallel The modules are connected in series to form a battery pack (or battery pack). The positive electrode of the battery is exposed under the mounting base. The sealing ring is stuck in the position of the battery rolling groove. The battery is assembled naked, that is, the battery is not wrapped with an insulating sleeve before assembly. The gap between the battery columns is filled with heat-conducting oil, and there are inlets and outlets on both sides of the bracket to insulate the heat-conducting liquid from circulating with the outside world. The first deflector and the second deflector have a trapezoidal convex structure. The flow plate is in elastic contact with the electrodes of the b...

Embodiment 2

[0049] The difference between this example and Example 1 is that the battery is wrapped with an insulating sleeve before assembly, and the lithium-ion battery pack prepared by this preparation process is counted as lithium-ion battery pack A2.

Embodiment 3

[0051] The only difference between this embodiment and Embodiment 1 is that the first deflector is a flat plate structure, and the pressure relief valve of the battery is covered by the first deflector. The lithium-ion battery pack prepared by this preparation process is counted as lithium-ion battery pack A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com