Lead-carbon battery negative electrode and preparation method thereof

A lead-carbon battery and negative electrode technology, which is applied in the field of lead-carbon battery negative electrode and its preparation, can solve the problems of affecting battery performance and batch stability, delaying the commercialization process, and expecting large differences, so as to improve mechanical and electrical properties , good consistency, and the effect of improving the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A lead-carbon battery negative electrode, the formula is as follows (mass fraction): flocculent carbon material 0.2%, black humic acid 0.1%, conductive graphite 0.06%, indium oxide 0.015%, barium sulfate 0.2%, binder polytetrafluoroethylene 0.6% %, thionyl chloride 0.5%, the balance of lead powder.

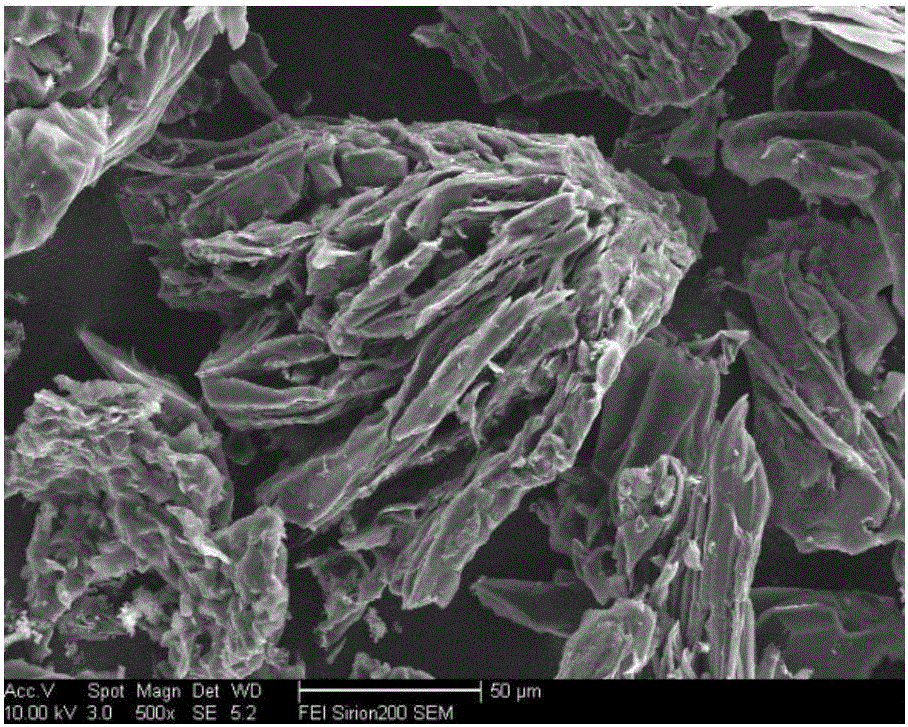

[0035] Among them: black humic acid is: dissolve humic acid in anhydrous ethanol, filter after fully stirring, spread the filter residue under a fume hood for ventilation, then put it in an oven at 60°C for 2 hours, and then dry it at 110°C , which is black humic acid. The preparation method of the flocculent carbon material is as follows: the highly oriented pyrolytic graphite plate is used as the positive electrode, the lead plate is used as the auxiliary electrode, electrolyzed in the electrolyte solution containing sulfate, and the current density is 10mA / cm 2 , and then dispersed, the dispersion speed is 3000r / min, time 4h.

[0036] The preparation method is as follo...

Embodiment 2

[0039] A lead-carbon battery negative electrode, the formula is as follows (mass fraction): wherein 2% of flocculent carbon material, 0.2% of black humic acid, 0.065% of conductive graphite, 0.01% of indium oxide, 0.25% of barium sulfate, binder polytetrafluoroethylene 0.6%, thionyl chloride 1.5%, the balance of lead powder.

[0040] Among them: the preparation method of black humic acid is: dissolve humic acid in absolute ethanol, filter after fully stirring, spread the filter residue under the fume hood for ventilation, then put it in an oven at 85°C for 1 hour, and then put it in an oven at 125°C ℃ drying, that is, black humic acid. The preparation method of the flocculent carbon material is as follows: the highly oriented pyrolytic graphite plate is used as the positive electrode, the lead plate is used as the auxiliary electrode, and electrolyzed in the electrolyte containing sulfate, the current density is 20mA / cm 2 , and then dispersed, the dispersion speed is 2000r / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com