Battery provided with protective layer and protective layer thereof

A protective layer and battery technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of loss of power storage and discharge function of the structure, unfavorable popularization, production process requirements and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

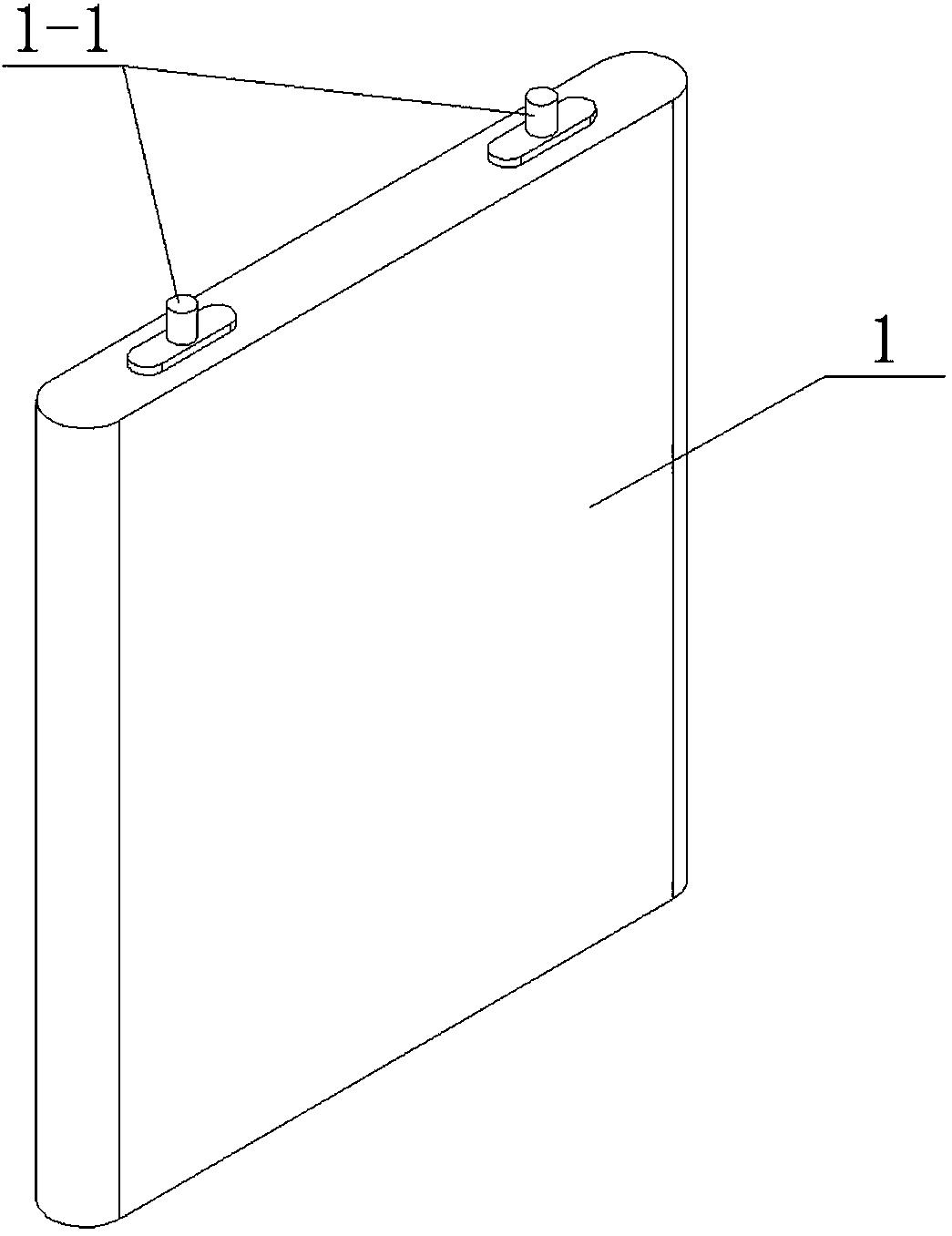

[0046] Such as Figure 8 , Figure 9 Shown is one of the embodiments of the present invention, in this embodiment, the outer surface of the battery 1 is provided with a protective layer 2, if the outer surface of the battery 1 needs to be provided with metal or non-metallic packaging, the protective layer 2 can also be arranged outside the battery On the packaging surface, the protective layer 2 is closely attached to the battery 1 or the battery outer packaging surface to seal the battery 1. The protective layer 2 is a hard layer or a soft layer, and the protective layer 2 is provided with a temperature adjustment device.

[0047] The protective layer 2 can wrap the battery 1 as a whole, including the electrodes, or can partially wrap the battery 1 except the electrodes.

[0048] The protective layer 2 can be made of materials such as silica gel or rubber, and is made on the surface of the battery 1 or the outer packaging of the battery by spraying, soaking, pasting, etc., a...

Embodiment 2

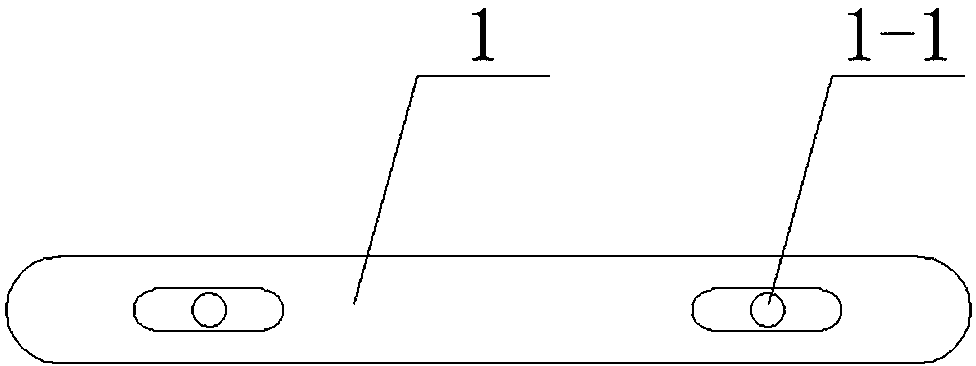

[0060] Such as Figure 10 , Figure 11 Shown is embodiment 2 of the present invention, and in this embodiment, protective layer 2 is provided with a plurality of grooves to form cooling groove 2-2, and the temperature regulating device of battery is formed by cooling groove 2-2, and cooling groove 2-2 It is mainly arranged on the upper and lower sides of the battery 1 .

[0061] Such as Figure 10 , Figure 11 As shown, the groove is in the shape of a circular groove, the depth of the groove is less than the thickness of the protective layer 2, and the bottom of the groove does not penetrate the protective layer 2, so that the temperature can be adjusted and the sealing protection performance of the protective layer 2 can be maintained. This design is only for the case where the battery needs to be cooled. The groove can also be designed as a polygonal groove.

Embodiment 3

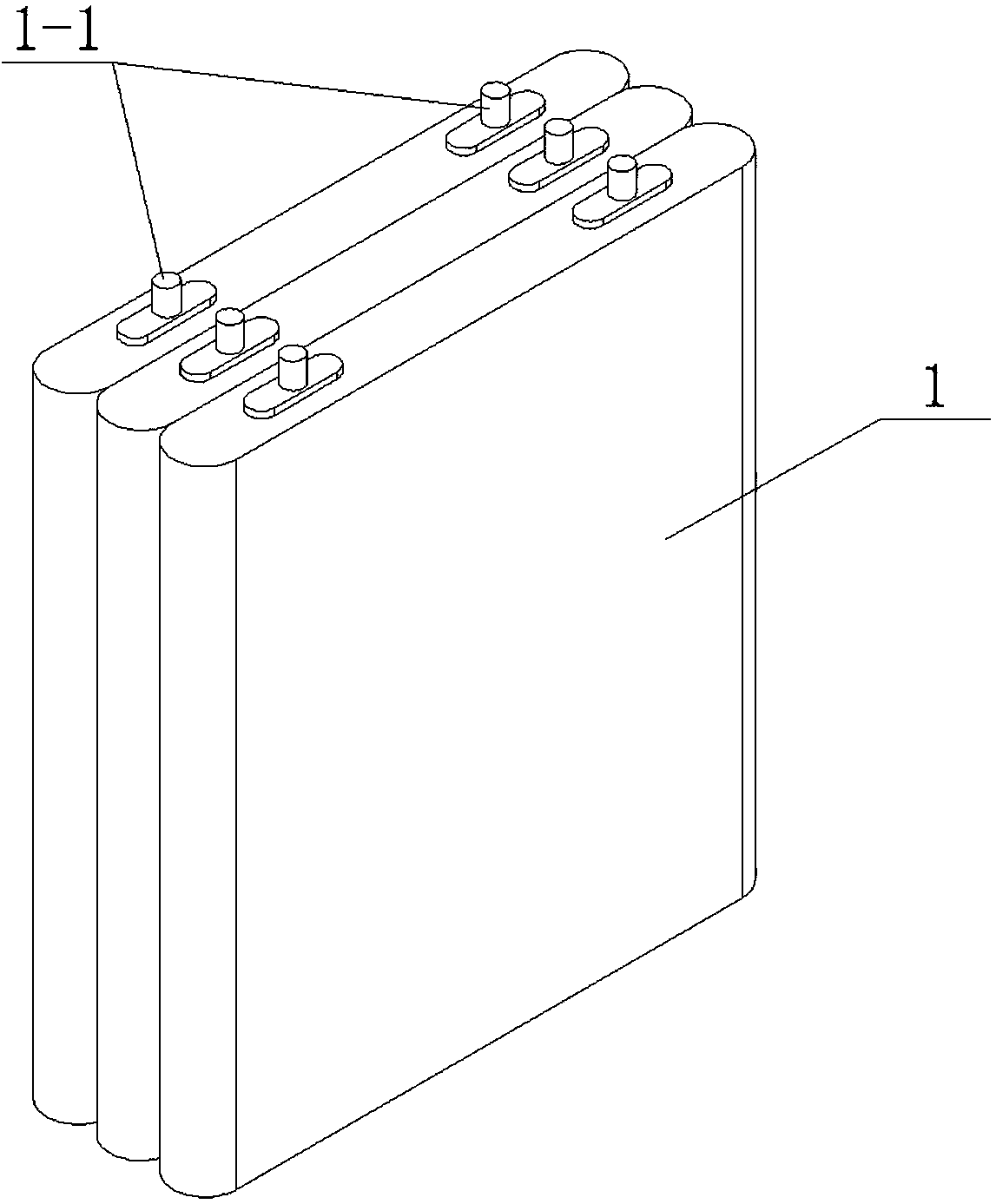

[0063] Such as Figure 12 , Figure 13 Shown is Embodiment 3 of the present invention. In this embodiment, the protection layer 2 is provided with several grooves to form the cooling groove 2-2, and the temperature regulating device of the battery is formed by the cooling groove 2-2.

[0064] Such as Figure 12 , Figure 13 As shown, the groove is in the shape of a long groove, the depth of the groove is smaller than the thickness of the protective layer 2, and the bottom of the groove does not penetrate the protective layer 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com