Automatic injection-molding production system and intelligent production method

A technology for production systems and injection molding products, applied in general control systems, control/regulation systems, and comprehensive factory control, etc., can solve the problems of large noise, untimely, and low production efficiency of injection molding equipment, and reduce manual participation , timely system maintenance, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

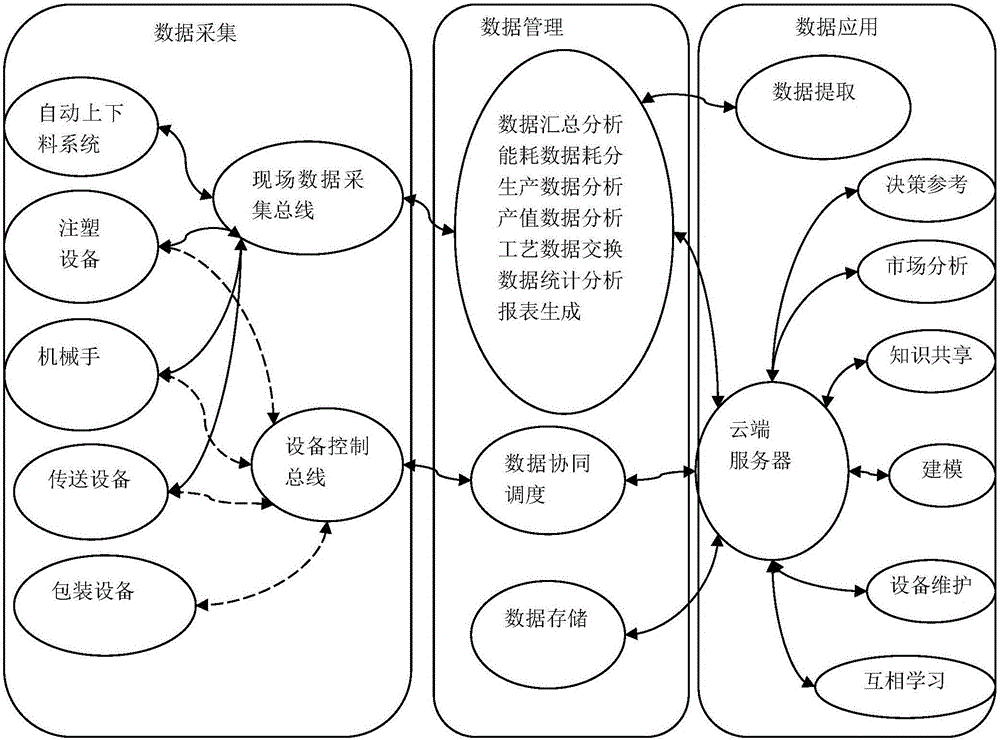

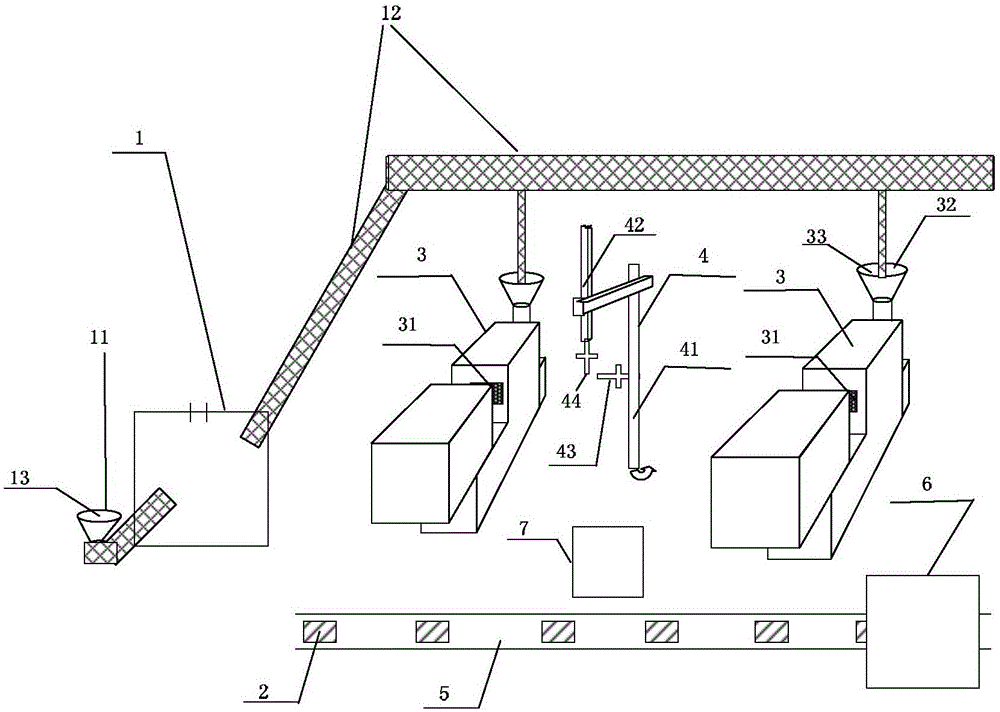

[0051] refer to figure 1 , an injection molding automatic production system, including cloud server, central control system, automatic loading and unloading system 1, injection molding equipment 3, manipulator 4, transmission system 5 and packaging equipment 6, automatic loading and unloading system 1, injection molding equipment 3, manipulator 4, The transmission system 5, the packaging equipment 6 and the central control system are connected through the field bus, and the central control system is connected to the cloud server. The central control system is used to receive the sensor feedback from the automatic loading and unloading system 1, the injection molding equipment 3 and the robot arm The data is sent to the cloud server. The cloud server is used to extract and analyze the sensor data sent by the central control system to form corresponding data files, and generate optimized control decisions for corresponding equipment and send them to the central control system. Th...

Embodiment 2

[0062] The injection molding automation intelligent production method of the injection molding automation production system of embodiment 1 includes:

[0063] Automatic loading and unloading system 1 automatically fills polymer materials and automatically transfers polymer materials to injection molding equipment 3 for injection molding;

[0064] The manipulator 4 takes out the injection molding product 2 from the injection molding equipment 3 according to the set optimal pick-up plan and checks the product quality, and then puts the injection molding product 2 into the conveying system 5 according to the quality level;

[0065] The conveying system 5 conveys the injection molded product 2 to the packaging equipment 6 for packaging and distribution;

[0066] The automatic loading and unloading system 1, the injection molding equipment 3 and the manipulator 4 all use sensors to collect the sensory data of the production process in real time and send them to the central control ...

Embodiment 3

[0078] This embodiment describes a specific intelligent production method in combination with Embodiment 1:

[0079] The central control system sends instructions through the industrial field bus to control the automatic loading and unloading system 1 to dry the polymer raw materials in the container and transport them to the feeding port of the injection molding equipment 3. The sensor on the feeding port detects enough materials and sends a preparation The processing signal is sent to the injection molding equipment 3 control system. After the injection molding equipment 3 receives the signal, it sends a processing instruction signal to the central control system. The central control system sends the injection molding process parameters and control related parameters to the injection molding equipment 3, and the injection molding equipment 3 enters the injection molding process. process. After plasticizing, injection, pressure holding, mold opening and other related processe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com