A kind of marine low-temperature storage tank covered with thermal insulation material and construction method thereof

A technology of thermal insulation material and low-temperature storage tank, which is applied in the method of container discharge, container filling method, fixed-capacity gas storage tank, etc., can solve the problems of low-temperature use performance of finished products, affecting the utilization rate of raw materials, and low construction efficiency. , to achieve the effect of improving efficiency, good thermal insulation effect and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

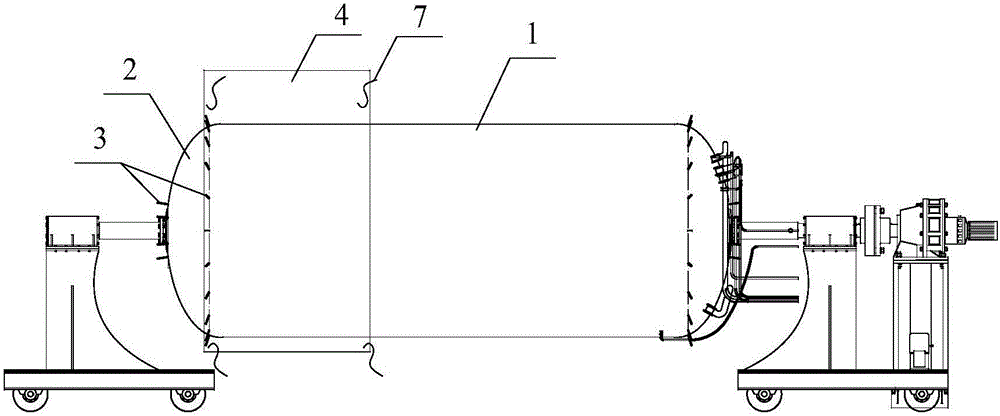

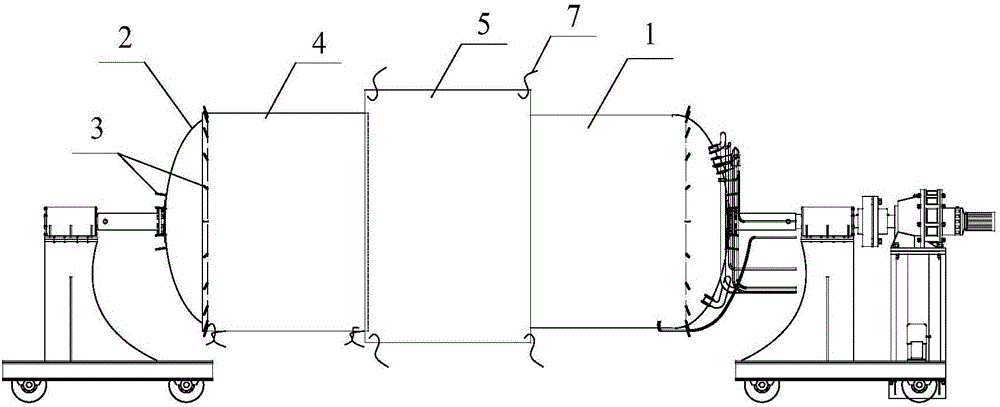

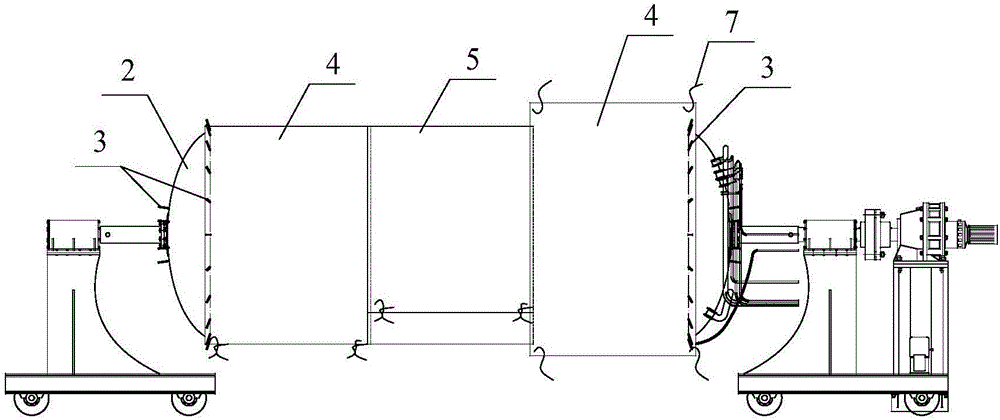

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0028] Such as Figure 1 to Figure 3 As shown, the marine low-temperature storage tank coated with thermal insulation material of the present invention includes a cylindrical cylinder body 1 and seal heads 2 located at both ends of the cylinder body 1, and a ring of steel nails 3 are respectively arranged along the circumference of the cylinder body 1 ( The tip of the steel nail 3 faces outwards), and the cylinder body 1 and the end cap 2 are covered in a multi-layer quilt. The quilt covered on the outer surface of each layer of cylinder body 1 comprises two end portion quilts 4 and a middle portion quilt 5, the end portion quilt 4 and the middle portion quilt 5 are rectangular, and the width dimension of each piece of quilt along the cylinder body 1 axial direction, It is greater than one-third of the axial length of the cylinder body 1; and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com