A treatment method for collapse of tunnel excavation working face by using pipe-through composite arch frame

A technology of tunnel excavation and processing method, which is applied in the direction of tunnel, tunnel lining, earthwork drilling and mining, etc. It can solve the problems of high cost, long period, high risk, etc., and achieve the effect of less preparation work, simple production and reduced process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

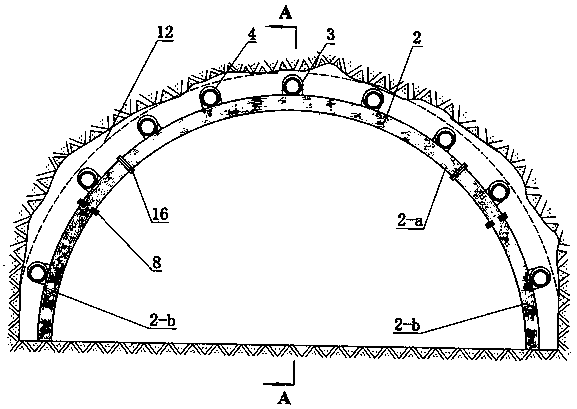

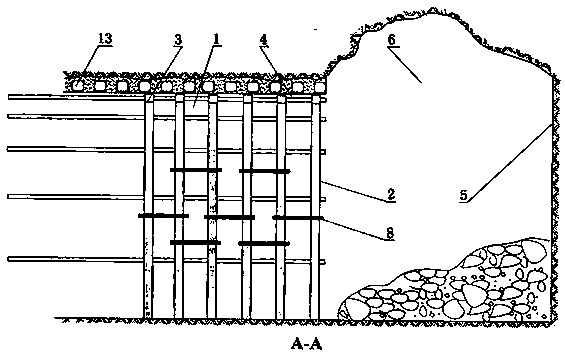

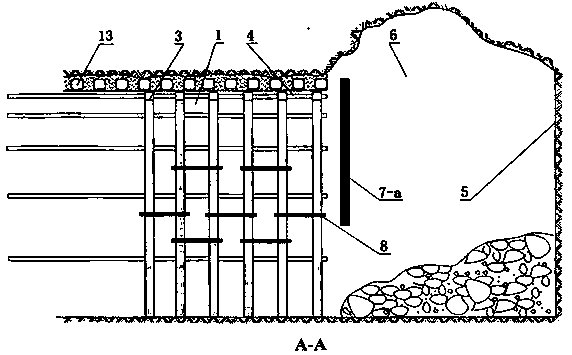

[0054] The method for treating the collapse of the tunnel excavation working face by using the combined pipe-through arch frame of the present invention includes the following steps.

[0055] Step 1: Set up collared arches 2 to eighth with collars 3 in the safe area 1, and adjacent collared arches 2 are connected by tie rods 8; steel pipes 4 penetrate the collars on the collared arches 2 3, and beyond the collar arch 2 closest to the working face.

[0056] Step 2: At the collapse area 6 about 200mm~500mm away from the ring arch 2, lift the vault section 7-a of the segmented support arch 7 to 150~200mm higher than the grid arch 13, and then Push the steel pipe 4 at the top of the upper arch section 2-a of the collar arch 2 to the landslide area 6 by more than 1000 mm, so that the advanced steel pipe 4 supports the vault section 7-a. Push other steel pipes 4 on the upper arch section 2-a of the collar arch 2 to the landslide area 6 for more than 1000mm, and the vault section 7-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com