Pulled locking device for earthquake isolation rubber bearing

A technology of locking device and vibration isolation rubber, applied in the direction of earthquake resistance, building components, etc., can solve the problem that the seismic response of the isolation bearing cannot be controlled in stages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

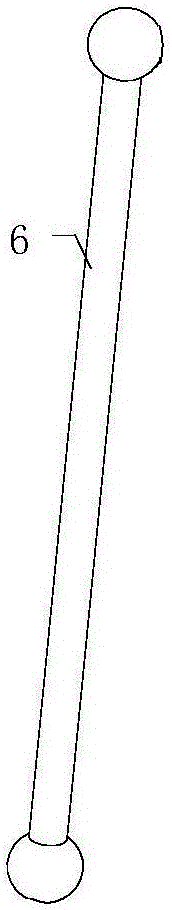

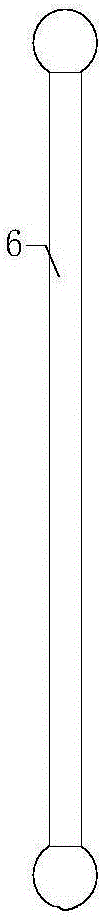

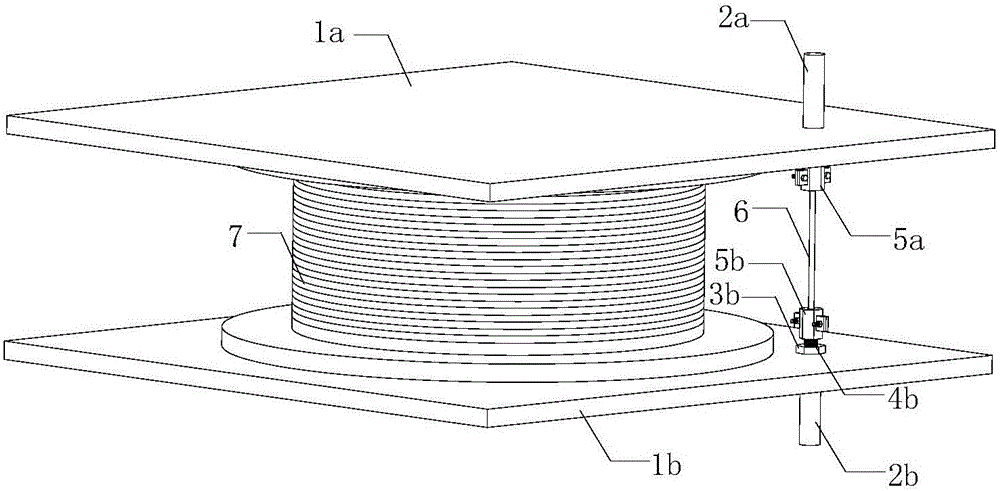

[0036] like Figure 1 to Figure 18 As shown, a tension locking device used on a vibration-isolating rubber bearing includes: mounting steel plates 1a, 1b, external sleeves 2a, 2b, large nuts 3a, 3b, threaded screws 4a, 4b, splicing nuts 5a , 5b, tie rod 6.

[0037] like figure 1 , Image 6 The common lead-core rubber support 7 is composed of a connecting plate 8 , a sealing plate 9 , a steel plate 10 , a rubber layer 11 , and a lead core 12 .

[0038] like Figures 14 to 16 As shown, the external sleeve 2 contains threads that can be matched with the threaded screw 4 . like Image 6 , Figure 7 As shown, the lengths of the outer sleeves 2a, 2b are greater than or equal to twice the overhanging lengths of the threaded screws 4a, 4b.

[0039] like figure 1 , figure 2 and Figure 7 As shown, the threaded screws 4a, 4b respectively pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com