Secondary tensioning prestressed assembly-type corrugated steel web composite beam and construction method thereof

A technology of corrugated steel webs and prestressed steel tendons, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc. Problems such as difficulty in replacement, to achieve the effect of reducing the steering gear and steel beam shock absorption, improving integrity and safety, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] The construction method of the secondary tension prestressed assembly type corrugated steel web composite beam of the present invention is:

[0029] 1. Prefabricated corrugated steel web beam beam body:

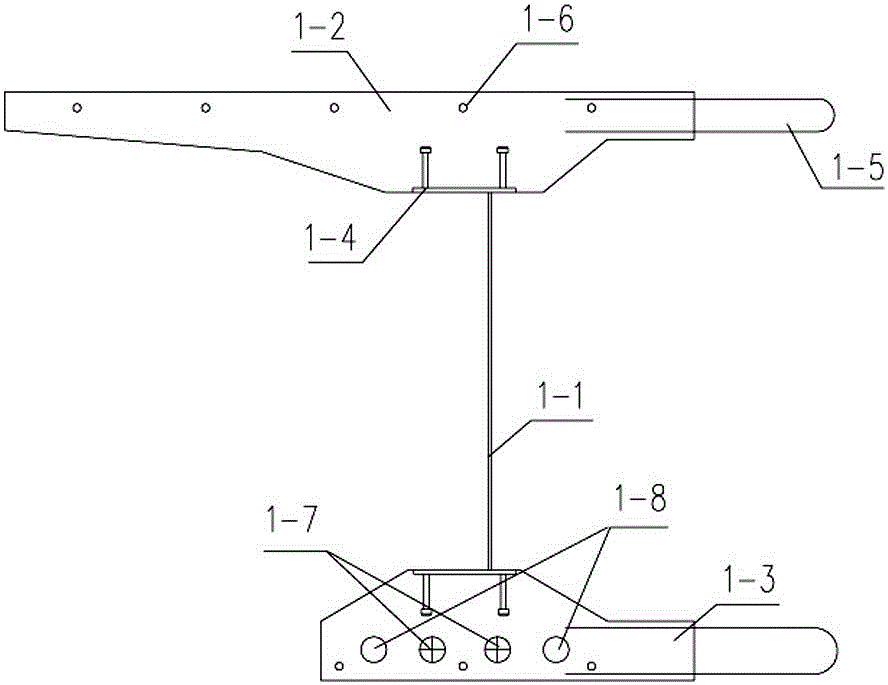

[0030] 1) When the post-tensioning method is used for the primary prestressed steel tendons, the prefabrication process is as follows: bind the ordinary steel bars in the concrete top slab 1-2 and the bottom slab 1-3, and connect the corrugated steel webs through shear keys 1-4 (or other connection forms). 1-1 is connected to the steel bars in the concrete top and bottom slabs, and pre-buried primary tension prestressed tunnels 1-7 and secondary tensioned prestressed tunnels 1-8; erected concrete formwork, poured concrete top slabs 1-2 and concrete bottom slabs 1-3. In the process of binding steel bars, reserve horizontal and vertical connecting steel bars 1-5 and 1-6. After the concrete strength of top plate 1-2 and bottom plate 1-3 meets the standard, remove the for...

example 2

[0037] If the secondary prestressed steel tendon is stretched before the beam is poured, then the construction method is:

[0038] 1. Prefabricated corrugated steel web girder body, the specific steps are the same as construction example 1.

[0039] 2. Composite beam erection and secondary prestressed steel tendon construction

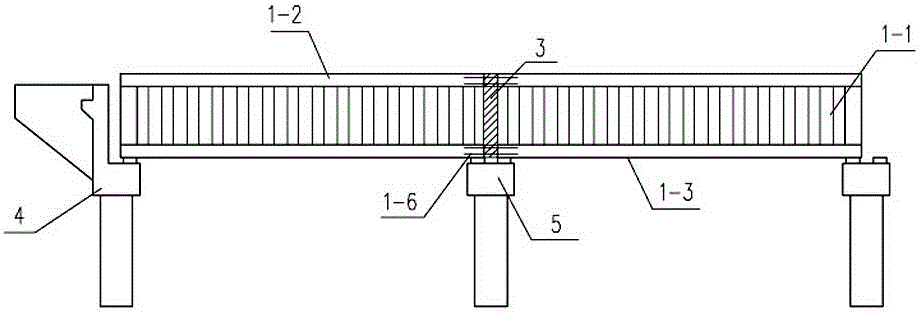

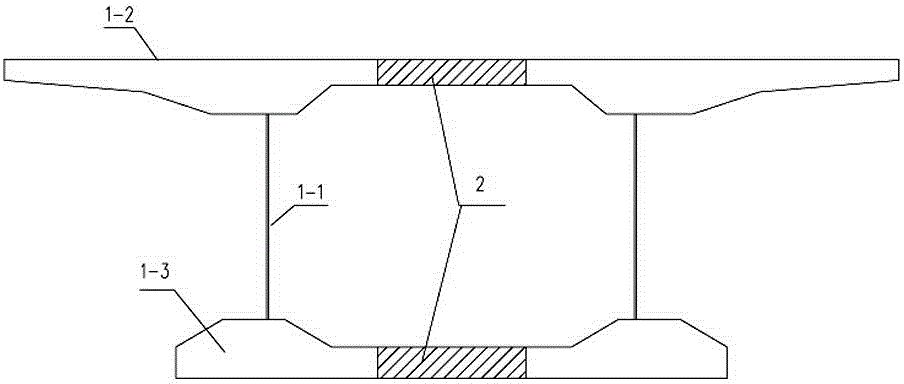

[0040] Such as figure 2 , Figure 4 As shown, the bridge abutment or bridge pier 4 is constructed on site, the temporary support 5 is installed, and the prefabricated girder body is hoisted to the abutment or bridge pier 4 with a crane or other equipment, and the transverse direction between two adjacent prefabricated girders is bound or welded. Connect the steel bars 1-5, and then pour the wet joint 2 between the adjacent beam bodies, so that the main beam forms a closed box section, see image 3 ; After the concrete strength of the wet joint 2 meets the requirements, the secondary prestressed steel strands 1-8 in the tensioned concrete floor 1-3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com