One-step copper smelting process and device

A copper smelting device and copper smelting technology, applied in crucible furnaces, electric furnaces, rotary drum furnaces, etc., can solve the problems of easily damaged and eroded retaining wall refractory materials, poor quality of crude copper, and affecting production efficiency, so as to save fire Refining process, simple structure, strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

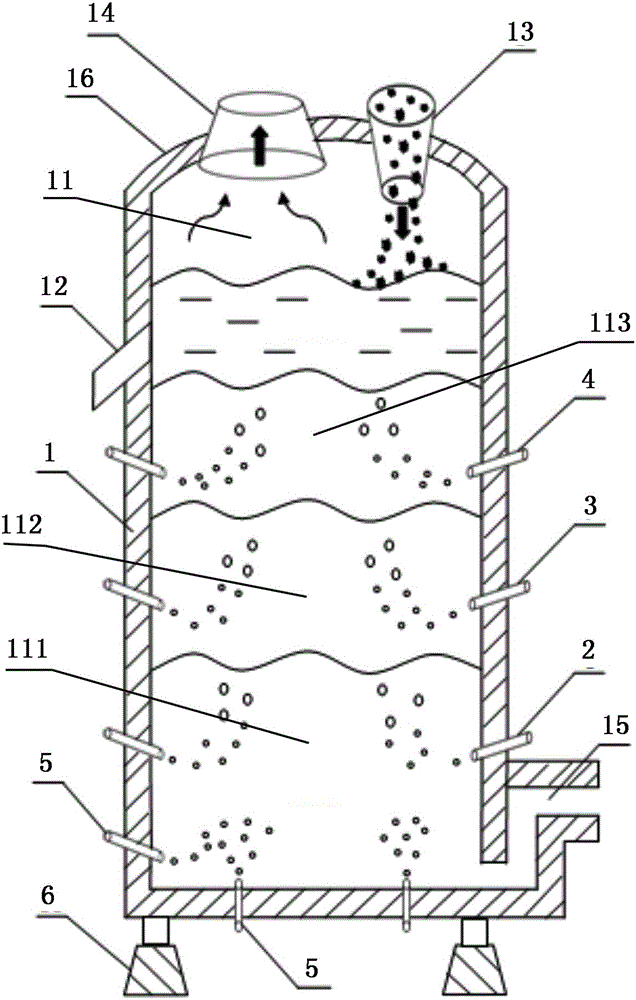

[0031] Such as figure 1 As shown, the one-step copper smelting device of the present invention includes a body of furnace 1 with a closed furnace chamber 11. The bottom of the body of furnace 1 is provided with a base 6, and the closed furnace chamber 11 is sequentially provided with a refining zone 111, a blowing chamber 11 from bottom to top. Smelting area 112 and smelting area 113, the furnace wall around refining area 111 is provided with a plurality of first spray guns 2, is provided with a plurality of second spray guns 3 on the furnace wall around blowing area 112, and the furnace wall around smelting area 113 A plurality of third spray guns 4 are arranged on the top, and a plurality of fourth spray guns 5 located below the third spray guns 4 are arranged on the furnace wall and bottom around the refining area 111, and a slagging outlet 12 is provided on the furnace wall above the smelting area 113. , The top wall 16 of the furnace body 1 is provided with a feeding port...

Embodiment 2

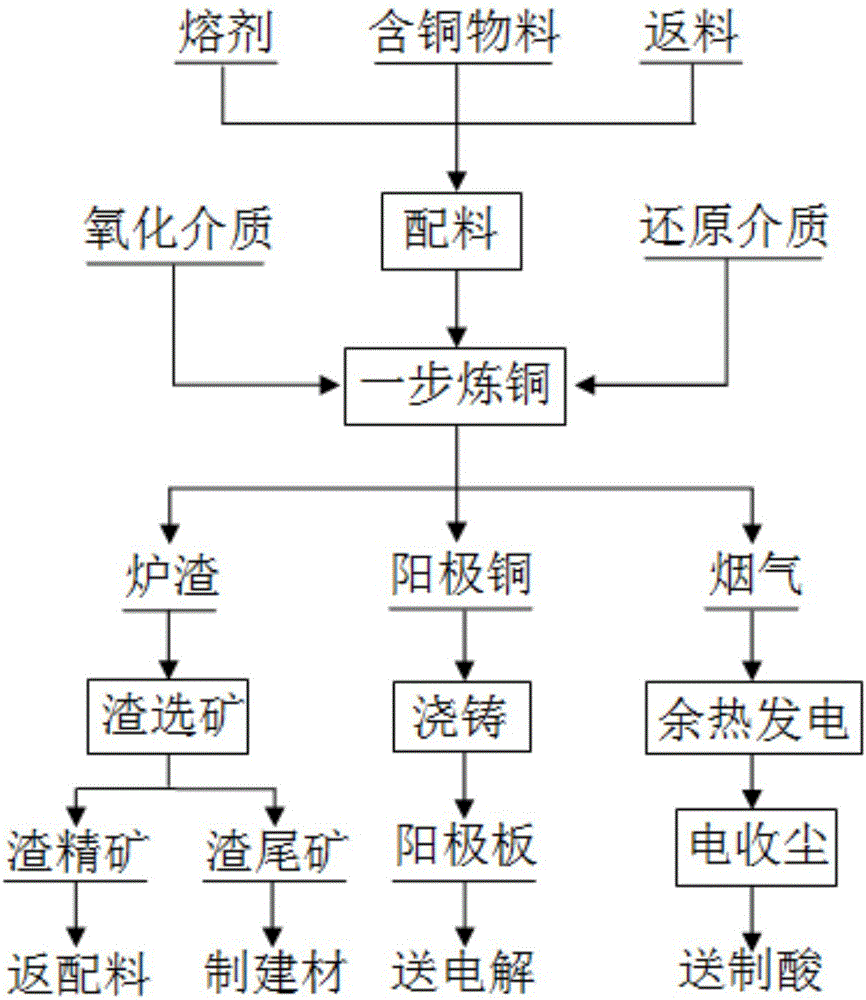

[0035] A kind of one-step copper smelting process that adopts said device, as figure 2 shown, including the following steps:

[0036] (1) After mixing the copper-containing material and flux, feed it into the furnace body 1 through the feeding port 13;

[0037] (2) Spray oxygen-enriched air into the smelting zone 113 through the third spray gun 4 for smelting, and smelt in the smelting zone 113 to form copper matte and slag, the grade of copper matte is 60%~75%, and the slag type Fe / SiO 2 In 1.4~2.2, the smelting temperature is controlled at 1180°C~1250°C, and the copper matte in the lower part of the smelting zone 113 is continuously oxidized into white matte. Because of its high density, it gradually moves down into the blowing zone 112. The generated copper matte is continuously replenished to the lower part of the smelting zone 113;

[0038] The oxygen-enriched air is sprayed into the blowing zone 112 through the second spray gun 3 for blowing. The blowing temperature is ...

Embodiment 3

[0046] A one-step copper smelting process, the one-step copper smelting process of this embodiment is basically the same as that of Embodiment 2, the difference is: the fourth spray gun 5 is not installed on the furnace wall around the refining area 111, but is installed at the bottom of the refining area 111 The fourth spray gun 5, during the refining and reduction process, only natural gas or pulverized coal is sprayed through the fourth spray gun 5 at the bottom of the refining zone 111 to deeply remove the O element in the copper liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com