Control method in the annealing furnace

A control method and an annealing furnace technology, applied in heat treatment process control, manufacturing tools, heat treatment equipment, etc., can solve the problems of furnace roll and strip slip accumulation, tension fluctuation, strip deviation, etc., to improve effective working time, Stabilizing tension and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

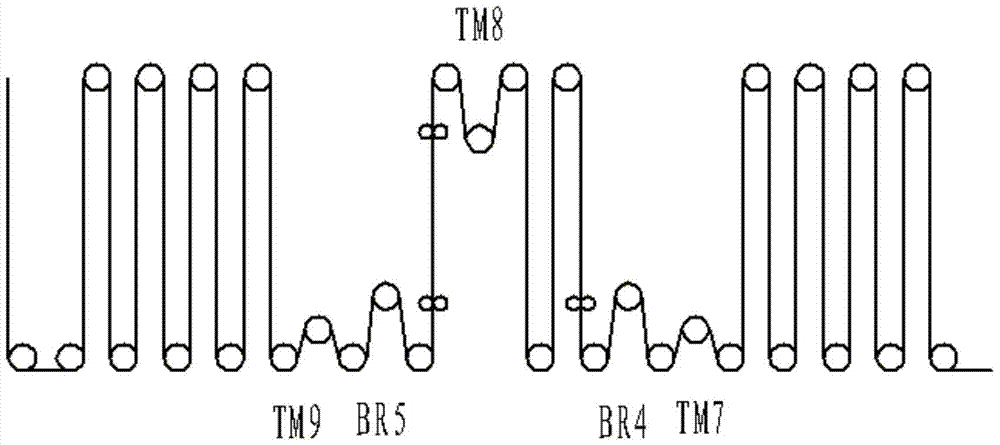

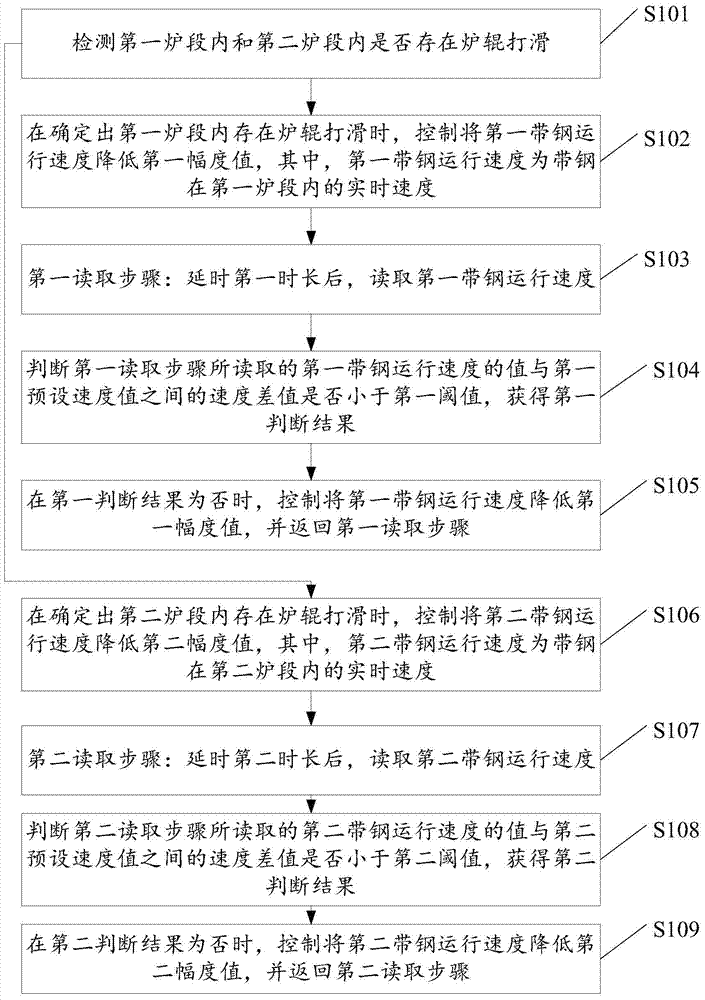

[0017] In order to solve the technical problem of slip accumulation between the furnace roll and the steel strip in the prior art, the present invention provides a control method in the annealing furnace, the general idea is as follows:

[0018] Through segmental monitoring of the annealing furnace to judge the slippage of the furnace rollers in the annealing furnace, the running speed of the strip steel is reduced in a fixed range in the slipping furnace section, the tension in the furnace is stabilized, and the technical problem of the accumulation of slipping between the furnace rollers and the strip steel is eliminated, thereby reducing It prevents belt breaking accidents caused by tension fluctuations, can effectively prevent deviation and broken belts in the furnace, reduce the scrap rate, and increase the effective working time of the unit.

[0019] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com