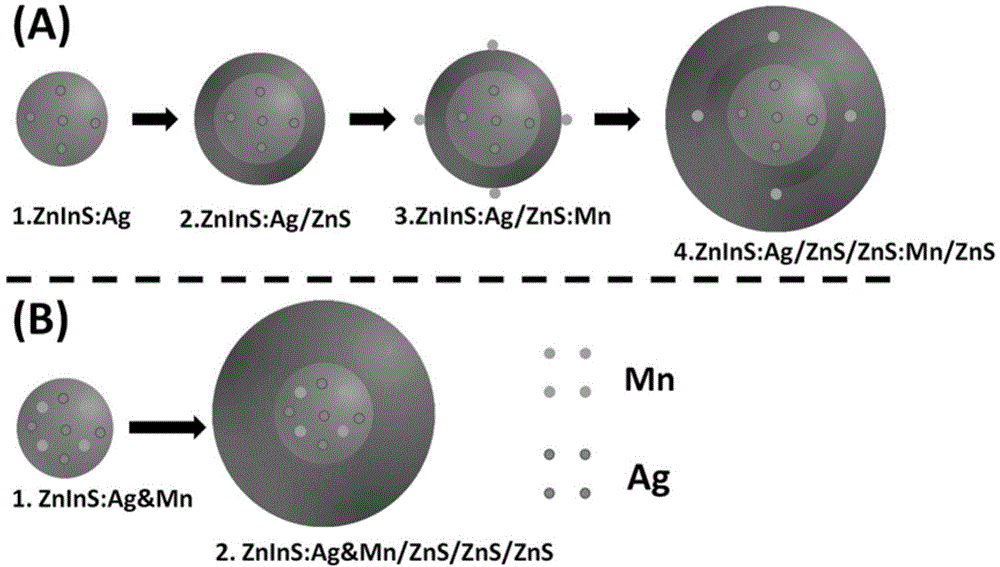

Preparation method for co-doped type and separately-coded type ZnInS/ZnS dual-emitter quantum dot

A quantum dot and dual-emission technology, which is applied in the fields of chemistry and nanomaterials, can solve problems such as the limitation of peak position mobility, and achieve the effects of flexible regulation, convenient raw material supply, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

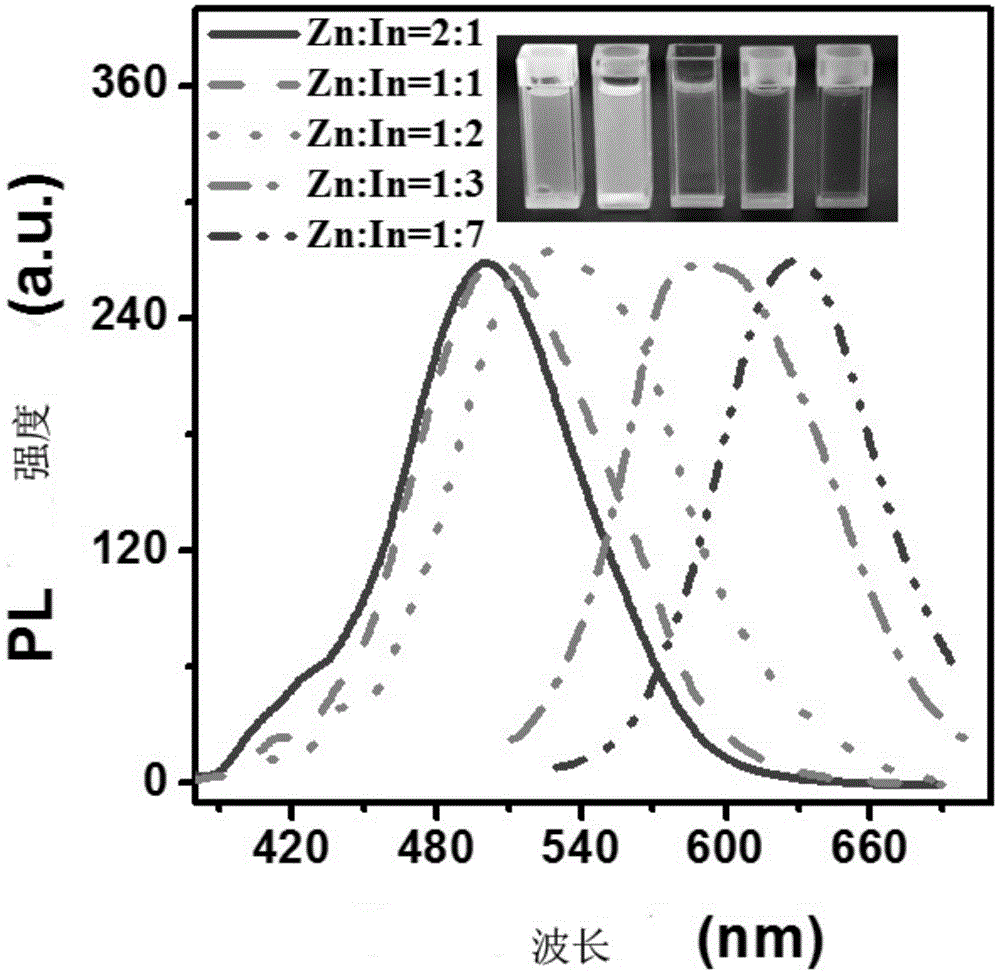

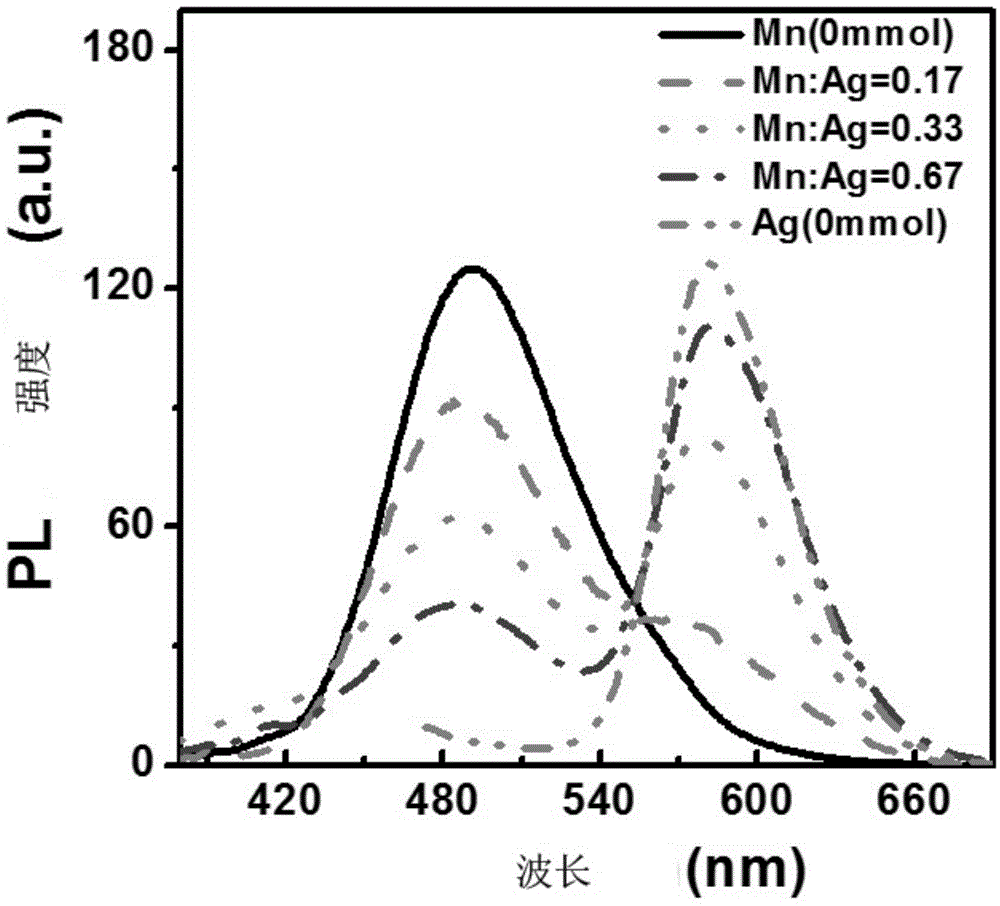

[0029] The AgNO used in this example 3 , Zn(O A ) 2 , In(O A ) 3 , Mn(O A ) 2 , S powder and other raw materials are analytical reagents, the solvent is oleylamine (OAm), and the ligand is DDT. The glass instruments used are rinsed with deionized water three times before use and then vacuum-dried. Quantum dots were prepared according to the following steps:

[0030] 1. Preparation of S precursor: Dissolve 10mmol S in 10ML OAm, then heat to 50°C, dissolve it under ultrasonic conditions, and finally add 10MLODE to dilute to make a 0.5mmol / ML S precursor solution;

[0031] 2. Preparation of Zn precursor: 8mmol Zn(O A ) 2 Dissolve in a mixture of 16ML OAm and 4MLODE, then stir for two hours at a temperature of 50°C to dissolve;

[0032] 3. Preparation of Mn precursor: 0.1mmmol Mn(O A ) 2 Dissolve it in 10ML OAm, and then heat it to 50°C under the protection of nitrogen to dissolve it, and prepare a 0.001mmol / ML Mn precursor solution.

[0033] 4. Preparation of white li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com