Claus tail gas treatment system and treatment method

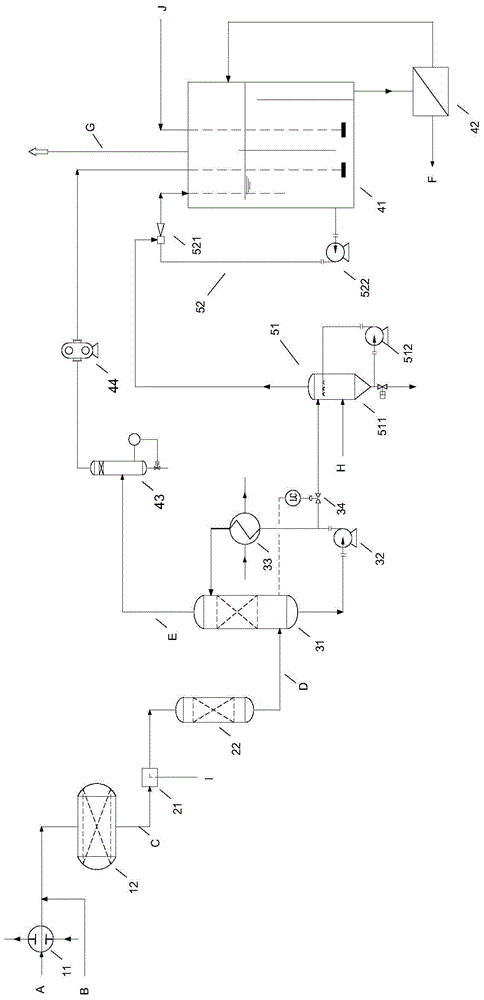

A Claus tail gas and treatment system technology is applied in the field of the tail gas treatment system of a Claus sulfur recovery device, which can solve the problems of high operating cost, complex process flow, and high investment, and achieves alleviating environmental pressure, broad application prospects, and lightening Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0108] The Claus tail gas treatment method of the present invention also includes another embodiment, specifically, comprises the following steps:

[0109] S1: React the Claus tail gas to be treated with reducing gas to transform the sulfur content into H 2 S;

[0110] S2: Rapidly cooling the tail gas of step S1 to 30-90°C;

[0111] S3: The tail gas of the S2 step and the liquid sulfur degassed gas from the Claus unit are subjected to oxidative desulfurization to make the H 2 S is transformed into elemental sulfur.

[0112] In a preferred embodiment, in step S2, the tail gas of step S1 is quenched to 40-80°C. In a more preferred embodiment, the tail gas of step S1 is quenched to 50-70°C.

[0113] In a preferred embodiment, the S1 step also includes reacting the Claus tail gas to be treated with a reducing gas, and then performing a hydrolysis reaction to make the residual COS, CS 2 convert to H 2 S.

[0114] According to the treatment system and / or treatment method of t...

Embodiment

[0117] Follow the steps below to treat Claus tail gas and liquid sulfur degassed gas.

[0118] a. Raw gas includes Claus tail gas and liquid sulfur degassed gas from Claus unit. Claus tail gas comes from the third-stage sulfur condenser of two-stage Claus unit. Its composition and properties are: H 2 S content 1.36% (V), SO 2 Content 0.34%, H 2 content 1.59%, COS content 0.08% (V), CO content 5.05%, CO 2 Content 44.45% (V), N 2 Content 10.72% (V), H 2 O content 36.3%, S X The content is 0.1%, the temperature is 160°C, and the pressure is 114Kpa; the liquid sulfur degassing gas comes from the liquid sulfur tank, and its composition and properties are: H 2 S content 0.844% (V), H 2 O content 3.74% (V), N 2 Content 75.4% (V), O 2 Content 20.0%, S X The content is 0.01%, the temperature is 138°C, and the pressure is 90KPa.

[0119] b. The Claus tail gas first enters the preheater, uses medium-pressure steam to raise the gas temperature to 238°C, and then enters the hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com