Preparation method for paclitaxel coating on surface of drug balloon

The technology of paclitaxel and balloon is applied in the field of preparation of paclitaxel coating on the surface of drug balloon, which can solve the problem that the lipophilic site of vascular tissue cannot be fully adhered and combined, the binding force of drug coating and balloon is weak, and the drug and blood vessel wall can be solved. Uneven contact and other problems, to achieve the effect of increasing adhesion performance, low cost and strong bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing a paclitaxel coating on the surface of a drug balloon, the preparation method comprising the following steps:

[0027] (1) Pretreating the balloon; soaking the balloon in the first organic solvent to obtain a modified balloon;

[0028] (2) Immerse the modified balloon in the paclitaxel coating solution, put it in a low-temperature device and let it stand for a certain period of time, and obtain the paclitaxel-coated balloon after drying;

[0029] (3) Repeat step (2).

[0030] Preferably, the first organic solvent is selected from ethyltrimethoxysilane, aminopropyltriethoxysilane, glycidyloxypropyltrimethoxysilane, vinyltrimethoxysilane, γ-ureidopropyl - One or more of trimethoxysilane, vinyltrichlorosilane and γ-glycidylpropyl-trimethoxysilane;

[0031] Preferably, the paclitaxel coating solution comprises paclitaxel and medical grade carrier dissolved in the second organic solvent according to the weight percentage, where...

Embodiment 1

[0037] (1) Pre-treat the surface of the balloon; soak the balloon in a mixed solution of vinyltrimethoxysilane and methanol (v:v=1:10), and then dry it in a constant temperature drying oven;

[0038] (2) Dissolve paclitaxel and urea (w:w=7:10) in ethanol solution, put it into a low-temperature device, and let it stand at -50°C for 20 hours;

[0039] (3) Take out the balloon and dry it in a constant temperature drying oven to obtain the drug balloon;

[0040] After determination, the content of paclitaxel on the surface of the drug balloon prepared in Example 1 was 531 μg, and the content of paclitaxel per unit area on the surface of the balloon was calculated to be 2.6 μg / mm 2 ;

[0041] The formula for calculating the content of paclitaxel per unit area on the surface of the balloon is: ρ=m / S; where,

[0042] m: the total amount of paclitaxel on the surface of the balloon, in μg;

[0043] S: Balloon surface area, in mm 2 ;

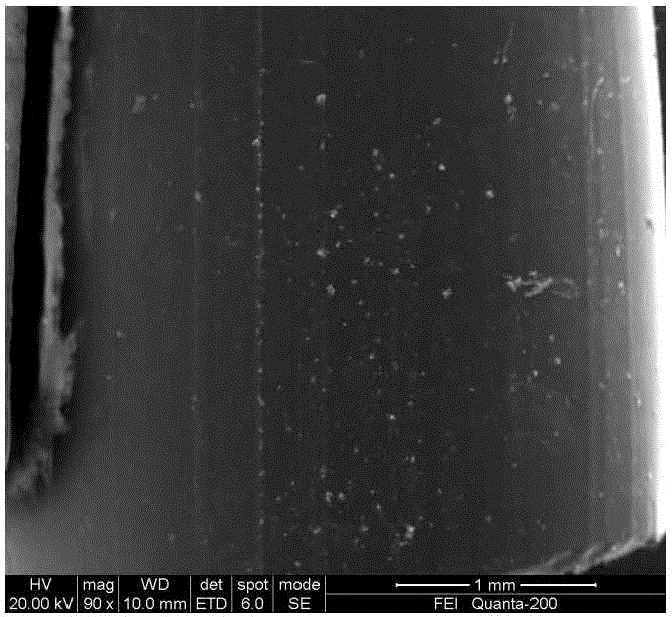

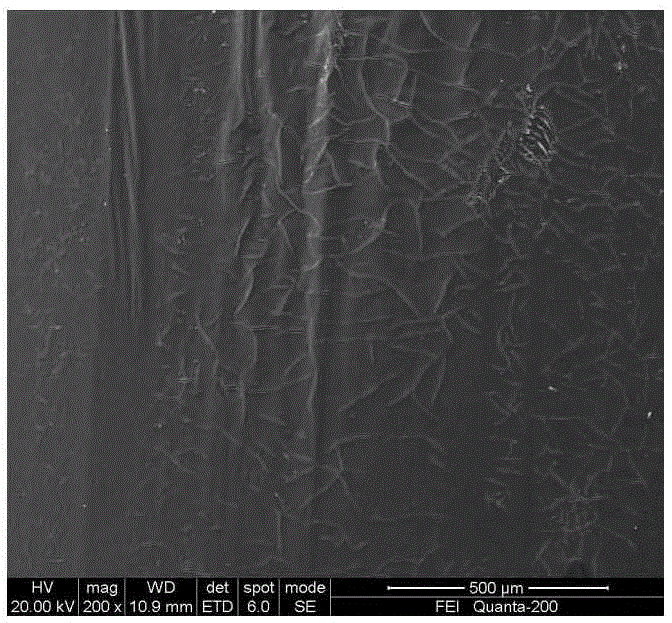

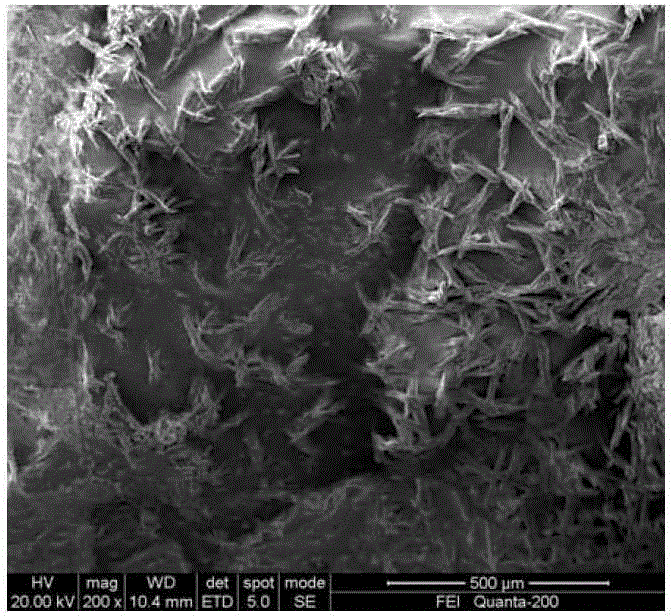

[0044] figure 1 It is the surface topography...

Embodiment 2

[0050] (1) Pretreat the surface of the balloon; immerse the balloon in a mixed solution of vinyltrichlorosilane and methanol (V:V=1:30), take it out after soaking, and put it in a constant temperature drying oven to dry;

[0051] (2) Dissolve paclitaxel and urea (w:w=3:5) in ethanol solution, put it into a low-temperature device, and let it stand at -45°C for 24 hours;

[0052] (3) Take out the balloon and dry it in a constant temperature drying oven to obtain the drug balloon;

[0053]After determination, the content of paclitaxel on the surface of the drug balloon prepared in Example 2 was 572 μg, and the content of paclitaxel per unit area on the surface of the balloon was calculated to be 2.42 μg / mm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com