Polyvinyl alcohol composition

A technology of polyvinyl alcohol and composition, which is applied in the field of ophthalmic drugs, can solve problems such as the need to improve the effect of eye drops, increase the mixing time and labor costs, and unfavorable use by consumers, so as to restore the epithelial cell barrier and improve the curative effect. Significant and good antibacterial and antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

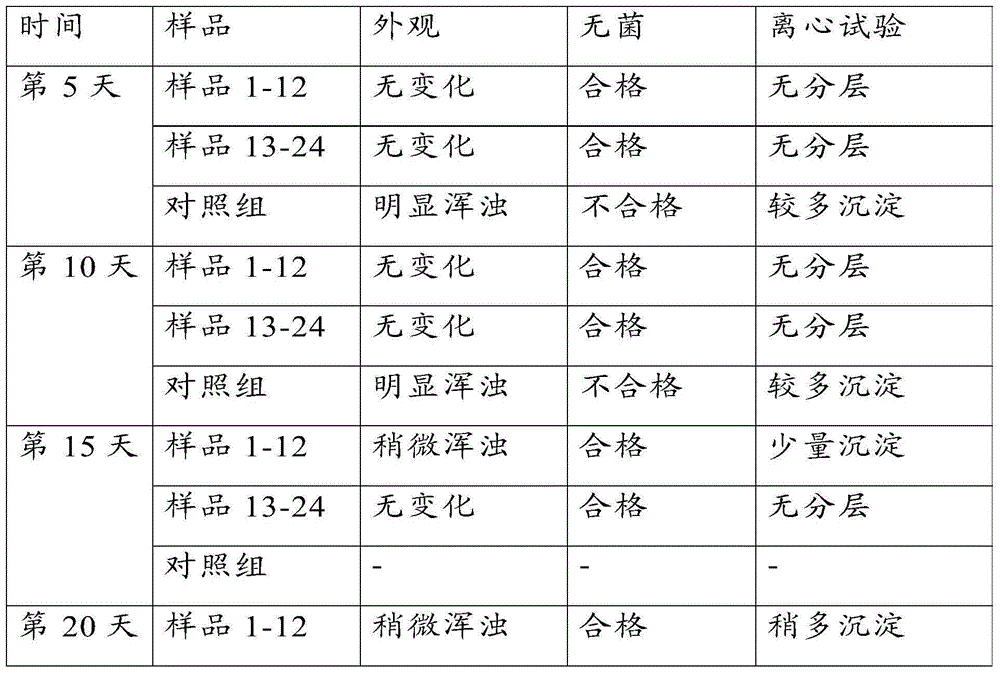

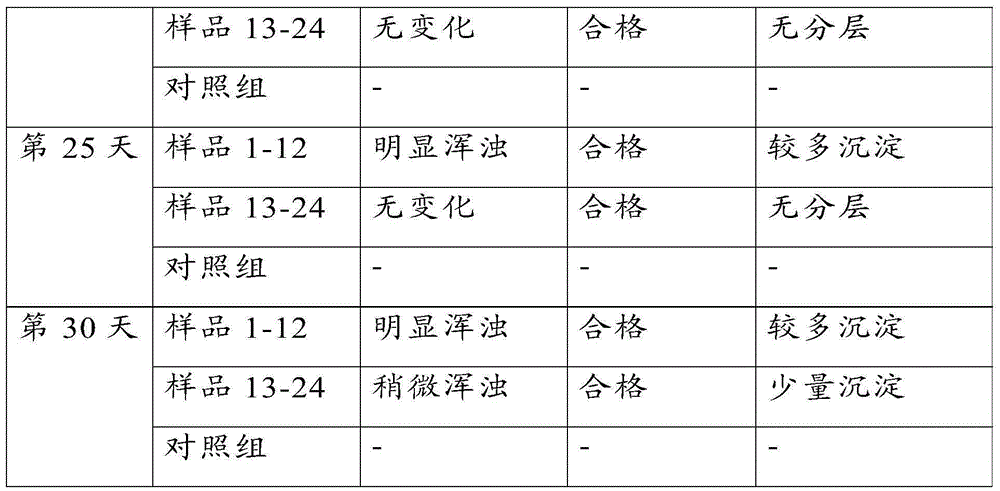

Examples

Embodiment 1

[0041] The polyvinyl alcohol composition is made into eye drops, and the specific steps are as follows:

[0042] Add 8 g of polyvinyl alcohol, 0.1 g of polyvinyl pyrrolidone, 0.5 g of xanthan gum and 0.5 g of fatty alcohol ester to 150 ml of water for injection, and mix well to obtain the first mixed solution;

[0043] Then add sodium chloride and sodium dihydrogen phosphate, adjust the osmotic pressure of the solution to be 300mOsm / L, and the pH value is 7.5 to obtain the target mixed solution;

[0044] After the target mixture is filtered and sterilized, it can be dispensed.

[0045] Group 2: Ultrasonic the obtained target mixture for 30 minutes, the power used for the ultrasonic wave is 5W; then filter and sterilize it, and dispense it.

Embodiment 2

[0047] The polyvinyl alcohol composition is made into eye drops, and the specific steps are as follows:

[0048]Add 15g of polyvinyl alcohol, 0.5g of polyvinylpyrrolidone, 5g of xanthan gum and 3g of sucrose ester to 200ml of water for injection, and mix well to obtain the first mixed solution;

[0049] Then add sodium sulfate and disodium hydrogen phosphate, adjust the osmotic pressure of the solution to be 310mOsm / L, and the pH value is 7.2 to obtain the target mixed solution;

[0050] Group 1: The target mixture is sterilized by filtration and then subpackaged.

[0051] Group 2: Ultrasonic the obtained target mixture for 10 minutes, the power used for the ultrasonic wave is 10W; then filter and sterilize it, and then dispense it.

Embodiment 3

[0053] The polyvinyl alcohol composition is made into eye drops, and the specific steps are as follows:

[0054] Add 10g of polyvinyl alcohol, 0.2g of polyvinylpyrrolidone, 1g of xanthan gum, 0.5g of fatty alcohol ester and 0.5g of sucrose ester to 170ml of water for injection, and mix well to obtain the first mixed solution;

[0055] Add potassium nitrate and potassium carbonate then, adjust the osmotic pressure of solution to be 305mOsm / L, pH value is 7.0, obtains target mixed solution;

[0056] Group 1: The target mixture is sterilized by filtration and then subpackaged.

[0057] Group 2: Ultrasonic the obtained target mixture for 25 minutes, the power used for the ultrasonic wave is 7W; then filter and sterilize it, and then dispense it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com