Spraying type mask and preparation method thereof

A technology of facial mask and mass ratio, which is applied in the field of spray mask and its preparation, can solve the problems of low viscosity, easy flow, and failure to achieve the effect of spraying, and achieve simple process steps, rapid increase in viscosity, and spraying effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

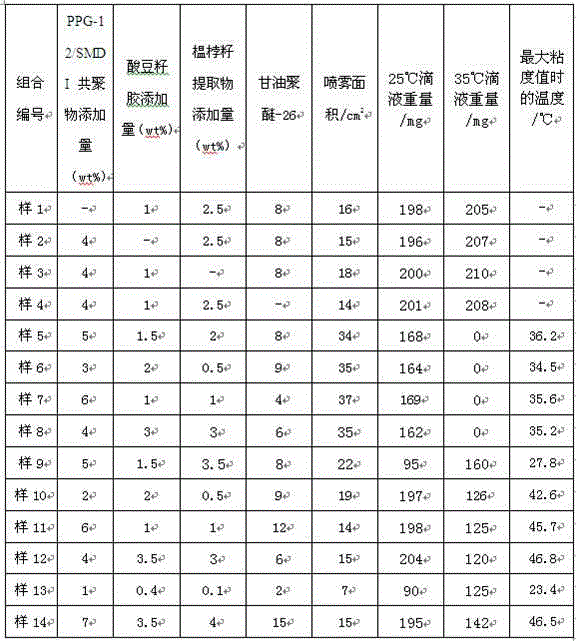

Image

Examples

Embodiment 1

[0037] A kind of preparation method of mist mask, comprises the following steps:

[0038] A. Weigh 3g of PPG-12 / SMDI copolymer (AEC PPG-12 / SMDI Copolymer), 1g of sour bean gum (GLYLOID 6C), 0.5g of quince seed extract (Quince Seed BG), 4g of polyglycerol Ether-26 (Genapol G260), mix well in a stainless steel container, heat to 52°C, keep soaking at this temperature for 24 hours, and then use EXAKT three-roll mill to grind to form a slurry;

[0039] B. Weigh 8.5g of the slurry and mix with 85g of deionized water at 5°C, stir evenly to obtain a transparent flowing liquid;

[0040] C. Add 3.1g of butanediol, 0.6g of 1,2-hexanediol and 0.6g of p-hydroxyacetophenone that have been mixed uniformly in advance; then add 0.05g of essence and 0.15g of PEG-40 hydrogenated castor oil that have been mixed in advance; then Add 1g of Pine algae extract and 1g of alcohol, keep stirring at 5°C, and get a spray mask with moisturizing effect.

[0041] In the spray mask prepared in this example...

Embodiment 2

[0043] A kind of preparation method of mist mask, comprises the following steps:

[0044] A. Weigh 4g of PPG-12 / SMDI copolymer (AEC PPG-12 / SMDI Copolymer), 2.5g of sour bean gum (GLYLOID 6C), 1g of quince seed extract (Quince Seed BG), 5g of polyglycerol Ether-26 (Genapol G260), mix well in a stainless steel container, heat to 55°C, keep soaking at this temperature for 24 hours, and then use EXAKT three-roll mill to grind to form a slurry;

[0045] B. Weigh 12.5g of slurry and 75g of deionized water at 15°C, mix them, and stir evenly to obtain a transparent flowing liquid;

[0046] C. Add 3.1g of butanediol, 0.6g of 1,2-hexanediol and 0.6g of p-hydroxyacetophenone that have been mixed uniformly in advance; then add 0.05g of essence and 0.15g of PEG-40 hydrogenated castor oil that have been mixed in advance; then Add 2g trehalose, 1g nicotinamide, 1g palm leaf extract, 1.5g PEG / PPG-17 / 6 copolymer, 2.5g propylene glycol, keep stirring at 15°C and get a spray mask with whitening...

Embodiment 3

[0049] A kind of preparation method of mist mask, comprises the following steps:

[0050] A. Weigh 5g PPG-12 / SMDI Copolymer (AEC PPG-12 / SMDI Copolymer), 1.5g Sour Bean Gum (GLYLOID 6C), 2g Quince Seed Extract (Quince Seed BG), 6g Glycerol Polymer Ether-26 (Genapol G260), mix well in a stainless steel container, heat to 53°C, keep soaking at this temperature for 24 hours, and then use EXAKT three-roll mill to grind to form a slurry;

[0051] B. Weigh 14.5g of slurry and 72.5g of deionized water at 20°C, mix them, and stir evenly to obtain a transparent flowing liquid;

[0052] C. Add 3.1g of butanediol, 0.6g of 1,2-hexanediol and 0.6g of p-hydroxyacetophenone that have been mixed uniformly in advance; then add 0.05g of essence and 0.15g of PEG-40 hydrogenated castor oil that have been mixed in advance; then Add 2g of Padina versicolor extract, 2g of polyethylene glycol-32, 1.5g of methyl gluceth-20, 1g of sorbitol, and 2g of alcohol, and keep stirring evenly at 20°C to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com