Flavored sauce and preparation method thereof

A sauce and flavor technology, applied in the field of flavor sauce and its preparation, can solve the problems of increasing environmental burden, wasting nutritional resources, etc., and achieve the effect of maintaining stability and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

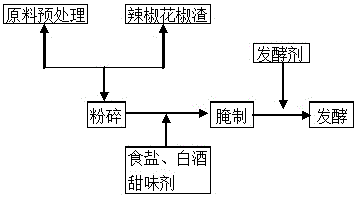

Method used

Image

Examples

Embodiment 1

[0023] Step 1, prepare fresh tomatoes, ginger and garlic, wash and dry, then weigh 500g of tomatoes, 100g of ginger and 40g of garlic, and 2 500g of chili and prickly ash residue that have been extracted with flavor substances, after mixing, use a plant grinder to pulverize;

[0024] Step 2, add 100g of salt, 10g of sucrose, and 10g of white wine to the pulverized sauce, stir with a mixer for 3 hours, and marinate;

[0025] Step 3, add 10 g of compound starter of Lactobacillus plantarum and Lactobacillus breve at a mass ratio of 1:1, and ferment at 10° C. for 30 days.

[0026] Step 4, sterilize the fermented sauce at 140°C for 3 seconds, and package.

[0027] The pH value in the fermented product slurry was measured by a pH meter to be 3.0, and the amino acid content in the fermented product slurry was determined to be 10.5 mg / mL by high performance liquid chromatography and an amino acid analyzer.

Embodiment 2

[0029] Step 1, prepare fresh tomatoes, ginger and garlic, clean them, dry them, then weigh 600g of tomatoes, 150g of ginger, 80g of garlic, 500g of capsicum and Chinese prickly ash that have extracted flavor substances, mix them, and crush them with a plant grinder;

[0030] Step 2, add 150g of salt, 20g of glucose, and 20g of white wine to the pulverized sauce, and stir with a mixer for 3 hours;

[0031] Step 3, add 40 g of compound starter of Lactobacillus plantarum and Lactobacillus breve at a mass ratio of 1:1, and ferment at 15°C for 20 days.

[0032] Step 4, sterilize the fermented sauce at 130°C for 8 seconds, and package.

[0033] Utilize the acidity meter to measure the pH value in the fermented product slurry to be 4.5, and utilize the high-performance liquid chromatography and the amino acid analyzer to measure the amino acid content in the fermented product slurry to be 14.3mg / mL.

Embodiment 3

[0035] Step 1, prepare fresh tomatoes, ginger and garlic, clean them, dry them, then weigh 500g of tomatoes, 120g of ginger, 60g of garlic, 600g of capsicum and prickly ash residue from which flavor substances have been extracted, mix them, and crush them with a plant grinder;

[0036] Step 2, add 150g of salt, 15g of maltose, and 15g of white wine to the pulverized sauce, and stir with a mixer for 3 hours;

[0037] Step 3, adding 20 g of starter compounded by Lactobacillus plantarum and Lactobacillus breve at a mass ratio of 1:1, and fermenting at 16° C. for 20 days.

[0038] Step 4, sterilize the fermented sauce at 125°C for 6 seconds, and package.

[0039] Utilize the acidity meter to measure the pH value in the fermented product slurry to be 4.0, utilize the high-performance liquid chromatography and the amino acid analyzer to measure the amino acid content in the fermented product slurry to be 15.2mg / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com