Detection system and detection method for detecting faults of photovoltaic module

A detection system and photovoltaic module technology, which is applied in the monitoring of photovoltaic systems, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of short service life and low power generation efficiency of photovoltaic modules, and achieve the effect of improving power generation efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

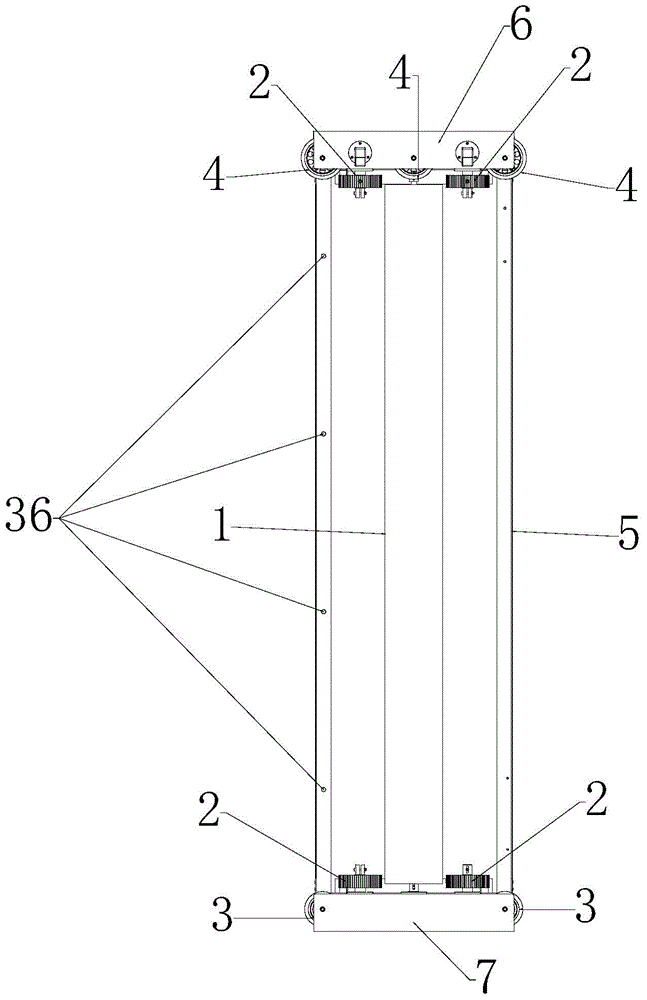

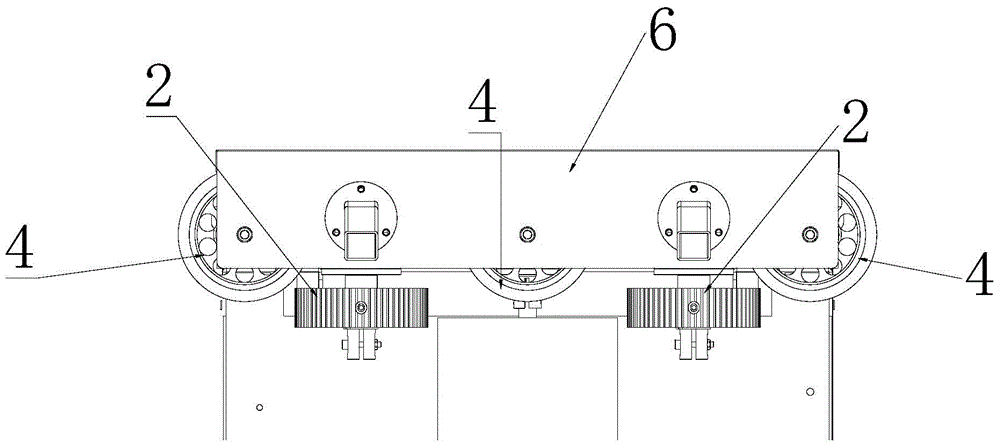

[0039] refer to Figure 1 to Figure 8 , shows a schematic diagram of a detection system applied to photovoltaic module fault detection provided by Embodiment 1 of the present application, and the detection system is set on an automatic cleaning device of a photovoltaic module. The automatic cleaning device is used to move along with the photovoltaic panels to be cleaned, and to clean the photovoltaic panels during the movement. During the cleaning process, the detection system simultaneously detects the temperature of the photovoltaic panel to be cleaned.

[0040] Specifically, the detection system includes a first temperature detection unit. In this embodiment, the first temperature detection unit is a thermal infrared temperature probe 36, which detects the temperature of the photovoltaic panel when the automatic cleaning device cleans the photovoltaic panel. The detection system also includes an intelligent control unit 13 shared with the automatic cleaning device. As a par...

Embodiment 2

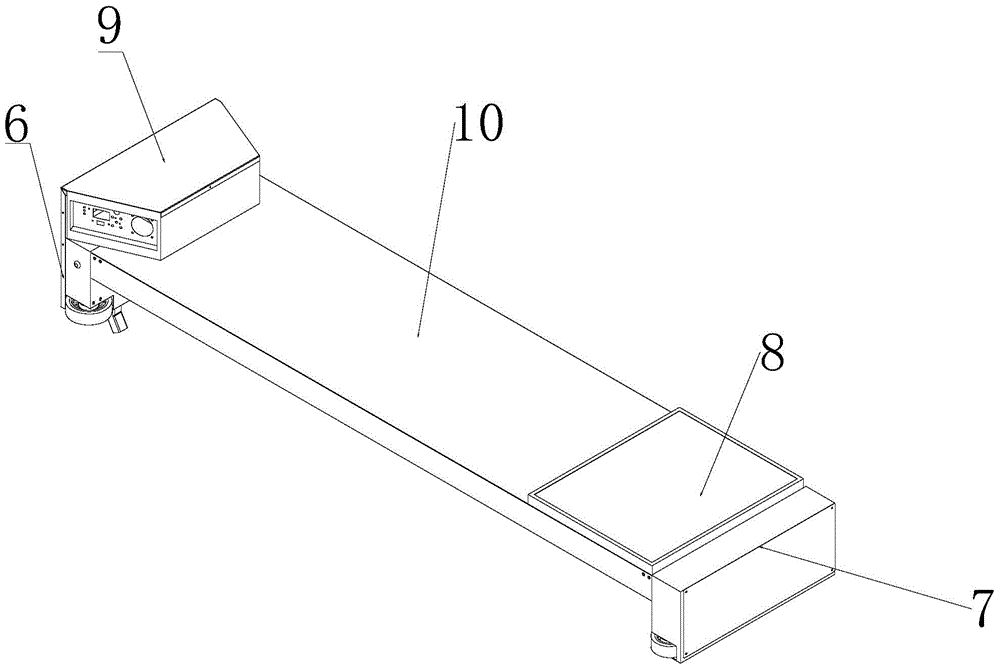

[0049] refer to Figure 9 to Figure 12 , shows a schematic diagram of the detection system applied in the fault detection of photovoltaic modules provided by Embodiment 2 of the present application. The main difference between Embodiment 2 and Embodiment 1 is that the automatic cleaning device where the detection system of Embodiment 2 is located The frame is segmented. Correspondingly, the thermal infrared temperature probes 36 are evenly distributed on the segmented frame. For the other same parts, refer to the above-mentioned embodiment 1, which will not be repeated here. It is specifically divided into two sections, or may be divided into more than two sections, which is not limited in this application. In this embodiment, the protective cover 10 and the brush 1 are also arranged in a two-stage segmented structure, which is described in detail as follows.

[0050] The frame includes two ends 6, 7 and a middle part, the middle part is segmented, and the protective cover 10...

Embodiment 3

[0053] This embodiment provides a detection system applied to photovoltaic module fault detection, specifically a thermal infrared detection system, which is integrated and installed in a photovoltaic module automatic cleaning device, such as Figure 13 to Figure 16As shown, the photovoltaic module automatic cleaning device includes an upper end box assembly 30, a middle section assembly 35, a lower end box assembly 33, a frame, a motor 12, a transmission assembly 31 and a cleaning assembly 32, and the upper end box assembly 30, the lower end box assembly 33 and the middle The segment assembly 35 is connected into a whole by the frame, and the cleaning assembly 32 is respectively installed between the upper end box assembly 30 and the middle section assembly 35, between the lower end box assembly 33 and the middle section assembly 35, and the upper end box assembly 30, the lower end The box assembly 33 and the middle section assembly 35 are respectively provided with driving wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com