Production method of proton exchange membrane fuel cell membrane electrode

A proton exchange membrane and fuel cell membrane technology, applied in the field of electrochemistry, can solve the problems of difficult to meet the entry and product exclusion, rapid decay of membrane electrode performance, low catalyst utilization rate, etc., to avoid catalyst delamination, improve life, The effect of offsetting thickness loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

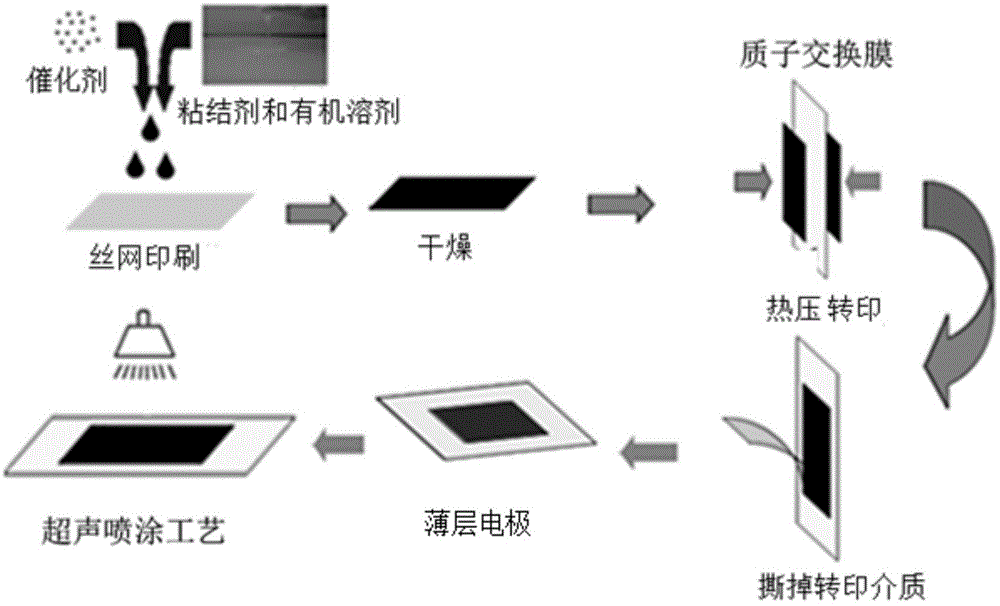

[0038] A method for preparing a proton exchange membrane fuel cell membrane electrode, comprising the following steps,

[0039] Step 1. Preparation of Electrocatalyst Slurry I

[0040] Weigh 60% Pt / C catalyst, add catalyst, stabilizer water, slurry diluent ethanol and isopropanol mixed solvent (1:1), thickener ethylene glycol, binder 5% ion exchange resin solution , Co-solvent dimethyl sulfoxide, the mass ratio of the above six components is fixed at 1:2:6.8:0.5:20:0.5, in which the ion exchange resin accounts for 50% of the dry weight of the electrocatalyst slurry I, adjust other components The metering ratio, the solid content is kept at 6.5%. After mixing, it is ultrasonically stirred for 60 minutes, then put into an emulsifier, emulsified at 13000r / min for 30 minutes, the dynamic viscosity value is 55mPa·s, sealed, and stored at 10°C;

[0041] Step 2. Preparation of thin-layer electrodes by screen printing process

[0042] A. Adjust the screen printing equipment, it will...

Embodiment 2

[0053] A method for preparing a proton exchange membrane fuel cell membrane electrode, comprising the following steps,

[0054] Step 1. Preparation of Electrocatalyst Slurry I

[0055] Weigh 60% Pt / C catalyst, add catalyst, stabilizer water, diluent mixed solvent of ethanol and isopropanol (1:1), thickener ethylene glycol, binder 5% ion exchange resin solution, Co-solvent dimethyl sulfoxide, the mass ratio of the above six components is 1:2:5:0.5:30:0.5, in which the ion exchange resin accounts for 60% of the dry weight of the electrocatalyst slurry I, adjust the metering ratio of other components, Keep the solid content at 6.5%. After mixing, ultrasonically stir for 30 minutes, then put it into an emulsifier, emulsify at 13000r / min for 30 minutes, the dynamic viscosity value is 30mPa·s, seal it, and store it at 10°C;

[0056]Step 2. Preparation of thin-film electrode

[0057] A. Adjust the screen printing equipment, it will have 6*6cm 2 The screen frame of the effective sc...

Embodiment 3

[0068] A method for preparing a proton exchange membrane fuel cell membrane electrode, comprising the following steps,

[0069] Step 1. Preparation of Electrocatalyst Slurry I

[0070] Weigh 60% Pt / C catalyst, add catalyst, stabilizer water, diluent mixed solvent of ethanol and isopropanol (1:1), thickener ethylene glycol, binder 5% ion exchange resin solution, Co-solvent dimethyl sulfoxide, the mass ratio of the above six components is 1:2:4:2:10.8:0.5, in which the ion exchange resin accounts for 35% of the dry weight of the electrocatalyst slurry I, adjust the metering ratio of other components, Keep the solid content at 7.5%. After mixing, ultrasonically stir for 30 minutes, then put it into an emulsifier, emulsify at 13000r / min for 30 minutes, the dynamic viscosity value is 55mPa·s, seal it, and store it at 10°C;

[0071] Step 2. Preparation of thin-film electrode

[0072] A. Adjust the screen printing equipment, it will have 6*6cm 2 The screen frame of the effective s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com