Contactless contactor with auxiliary contact

A non-contact contactor and auxiliary contact technology, applied in relays, relay ventilation/cooling/heating, electrical components, etc., can solve problems such as power loss, burned motor coils, contact ablation, etc., to improve service life , to ensure the cooling effect, to avoid the effect of false triggering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

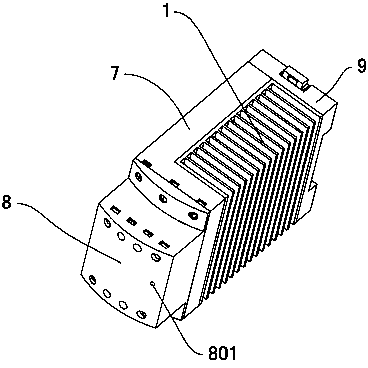

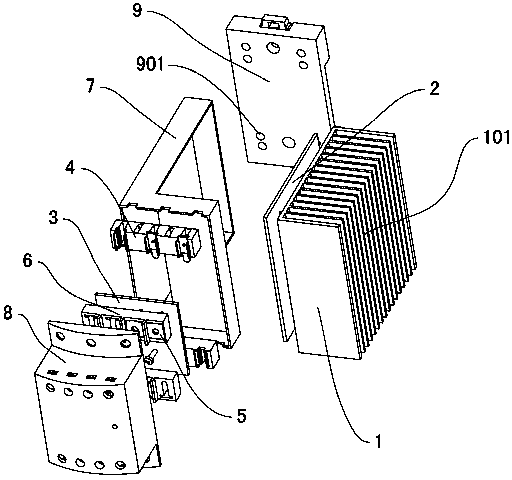

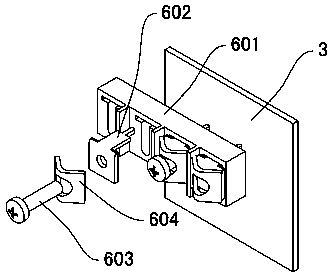

[0060] Refer to attached Figure 1~2 , the non-contact contactor with auxiliary contacts includes a radiator 1, a main circuit board 2, an auxiliary circuit board 3, a main terminal 4, an auxiliary terminal 6, a main circuit housing 7, an auxiliary circuit housing 8 and a fixing plate 9. The inner side of the vertical part of the L-shaped main circuit housing 7 and the front side of the horizontal part are open, the main circuit board 2 is placed in the vertical part of the main circuit housing 7, the main terminal 4 is fixed on the front end of the radiator 1, and placed side by side In the horizontal part of the main circuit housing 7, it is connected with the main circuit board 2 by wires, and the thyristor element 201 of the main circuit board 2 ( Figure 4 ) is fixed on the side of the radiator 1, and the other side of the radiator 1 is provided with multiple vertical cooling fins 101. The side surfaces are all arranged on the same plane as the corresponding side surface...

Embodiment 2

[0086] refer to Figure 15 The difference between this embodiment and Embodiment 1 is that the main circuit housing 7 is T-shaped, the main circuit board 2 is placed in the vertical part of the main circuit housing 7, and the two sides of the vertical part of the main circuit housing 7 are respectively provided with radiators 1 , can cool both sides of the main circuit board 2 at the same time, and the components on the main circuit board 2 can be arranged on both sides of the substrate, further improving the heat dissipation effect and adapting to frequent switching. Other structures are with embodiment 1.

[0087] refer to Figure 16 The difference between this embodiment and Embodiment 1 is that in the three-phase non-contact contactor module, the bidirectional thyristor T1 is realized through the parallel connection of thyristors T4 and T7, the bidirectional thyristor T2 is realized through the parallel connection of thyristors T5 and T8, and the bidirectional thyristor T...

Embodiment 3

[0089] refer to Figure 17 , the main circuit board 2 (not visible in this figure) is fixed on the front side of the radiator 1, and the radiator 1 is provided with cooling fins 101 extending to the rear. The main circuit housing 7 is fixed in front of the radiator 1 and covers Located on the outside of the main circuit board 2, preferably an auxiliary circuit board 3 can also be fixed at the front end of the main circuit board 2, the auxiliary circuit housing 8 is fixed on the front side of the main circuit housing 7 and is covered on the outside of the auxiliary circuit board 3. Other structures are with embodiment 1.

[0090] refer to Figure 18 The difference between this embodiment and Embodiment 1 is that the protection circuit composed of the resistor R7 and the capacitor C4, the resistor R8 and the capacitor C5, and the resistor R9 and the capacitor C6 respectively connected in parallel at both ends of the triacs T1 to T3 is omitted. Other circuit structures are the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com