Inserting key slot type steel pipe support frame connecting device

A steel pipe bracket and connecting device technology, applied in the field of steel pipe scaffolding, can solve the problems of time-consuming and laborious installation and disassembly, corrosion of threads and nuts, and influence on connection quality, etc., and achieve the effects of simple connection, improved work efficiency, and simple and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

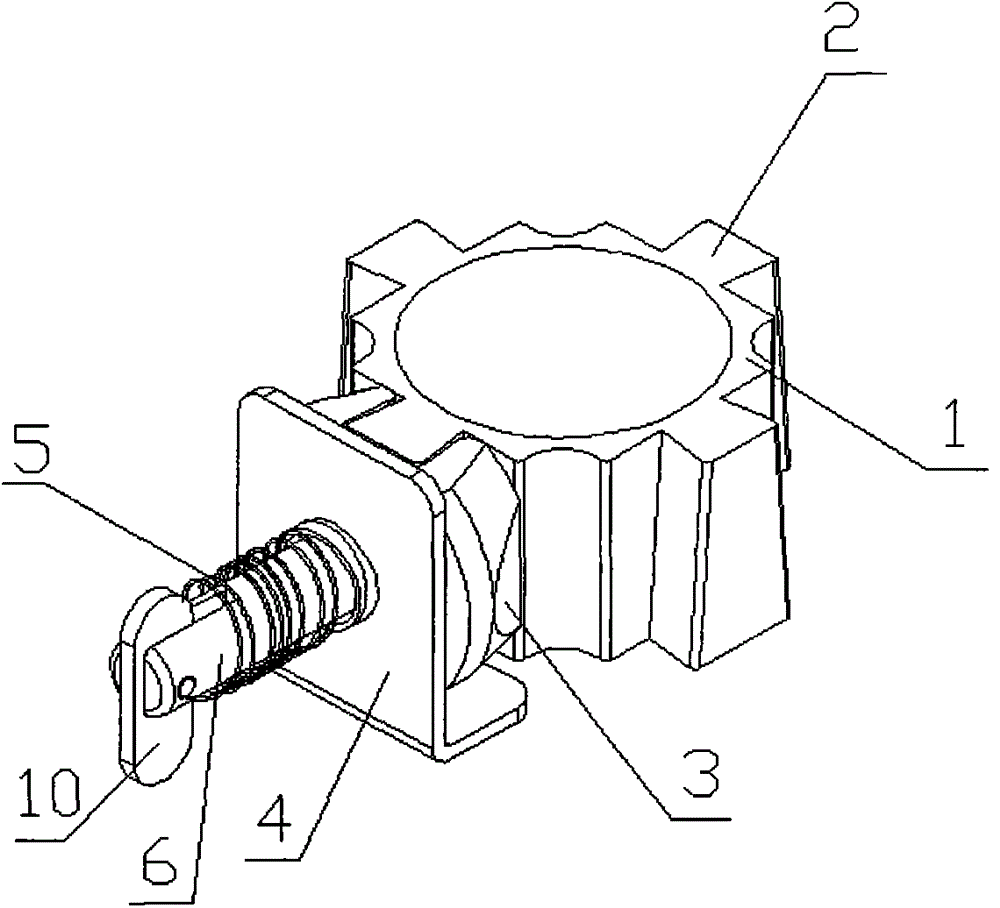

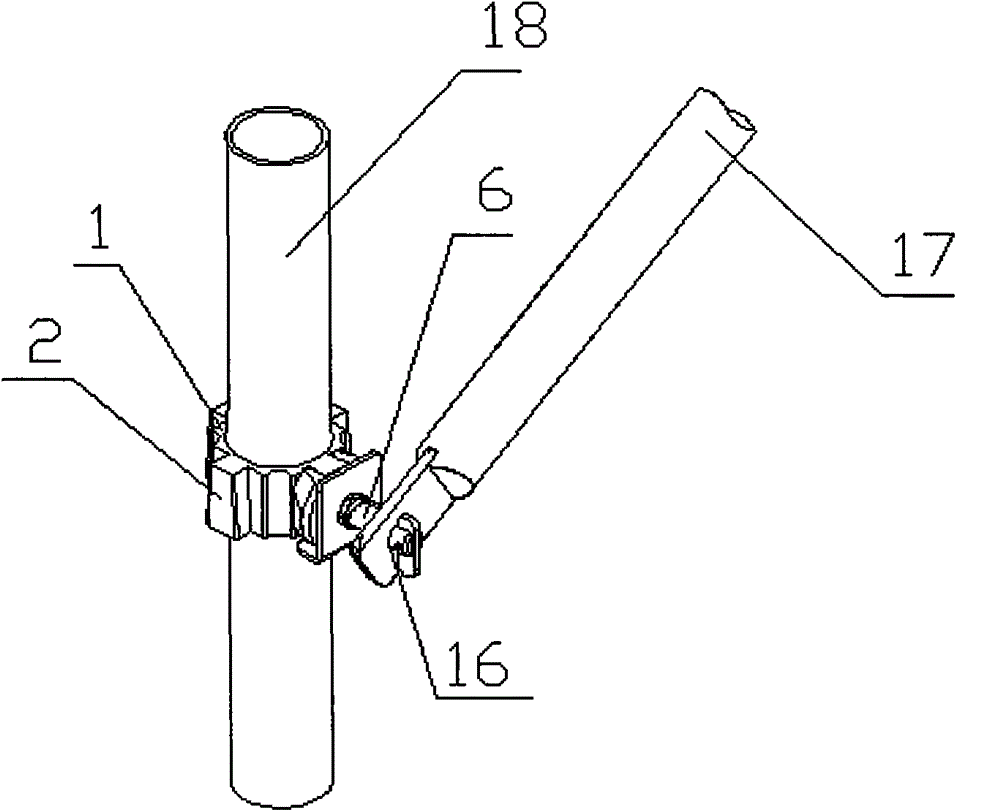

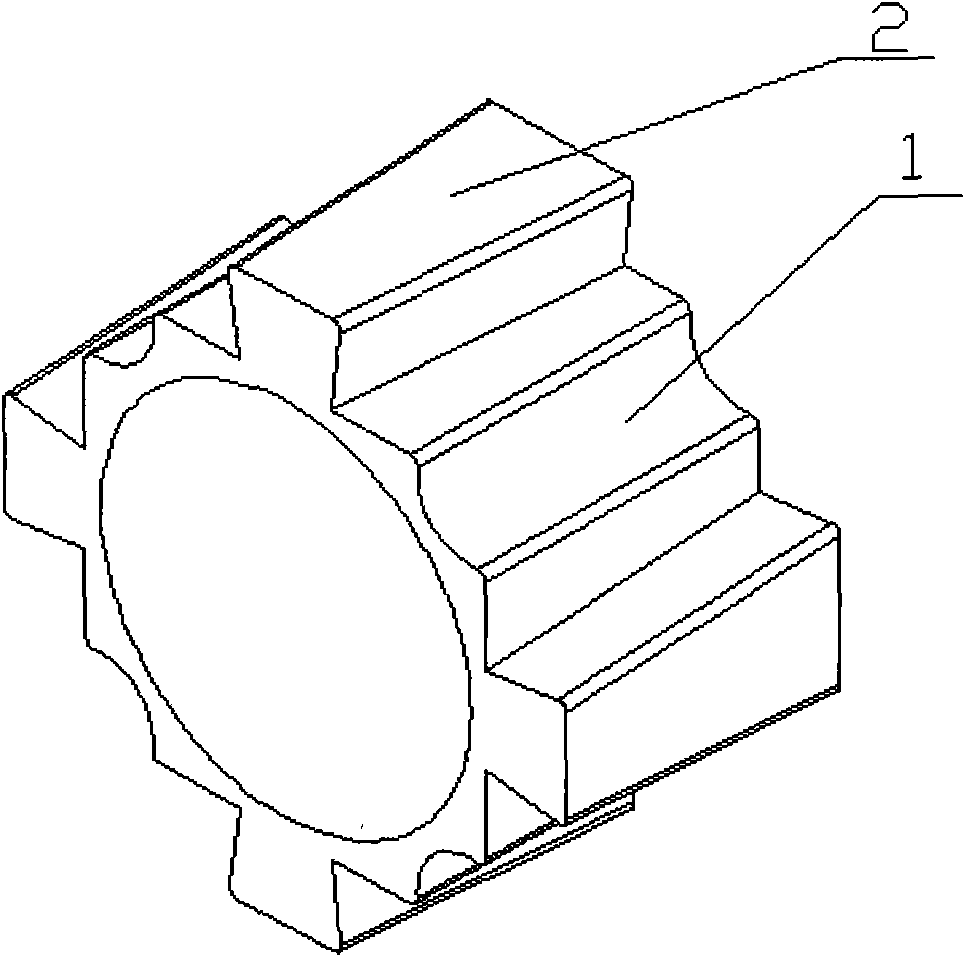

[0023] refer to figure 1 , figure 2 , Figure 4 and Figure 5 As shown, the present invention provides a socket-type keyway type steel pipe support connection device, which is used to fixedly connect the vertical rod 18 and the oblique rod 17, and includes a socket base 1 and a tapered protrusion arranged on the socket base 1. head 2. The center of the socket base 1 is a circular hole for socketing the vertical rod 18 . The shape of the tapered convex head 2 is narrow inside and wide outside, narrow at the top and wide at the bottom. It also includes a socket base, which includes a plug-in 3 , a blocking piece 4 , a spring 5 and a lock pin 6 . The front end of the plug-in 3 includes a tapered groove 7 adapted to the tapered protrusion 2 , and the rear end of the plug-in 3 is connected to the locking pin 6 . The baffle piece 4 is L-shaped, the L-shaped lower horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com