pH-responsive amino sodium lignosulphonate as well as preparation method and application thereof

A sodium lignosulfonate, amine-based technology, applied in botanical equipment and methods, applications, animal repellents, etc., can solve problems such as pH responsiveness that is not involved, and achieve widening product added value, widening applications, The effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

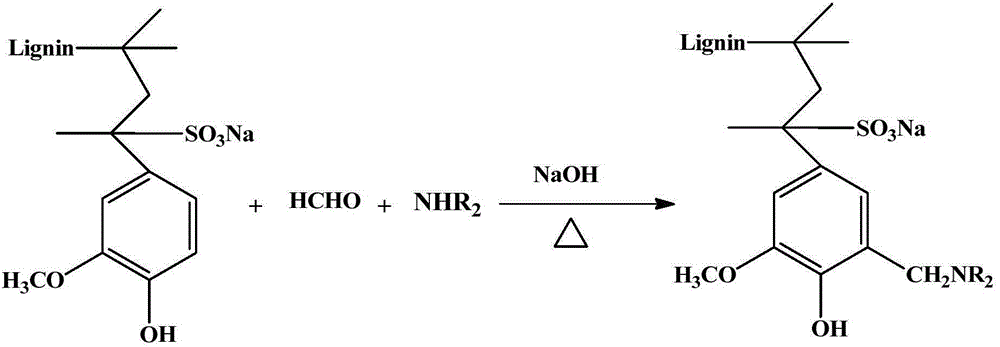

[0041] (1) Dissolve 100g of sodium lignosulfonate in 400g of water, adjust the pH to 12, activate in a water bath at 50°C for 0.5h, add 50g of diethylenetriamine, slowly add 50g of formaldehyde dropwise, and complete the dropwise addition within 0.5h. Raise the temperature to 70°C and continue the reaction for 4 hours to obtain a sodium lignosulfonate solution;

[0042] (2) Extract the sodium amine lignosulfonate solution with 100 mL of ethanol, then wash and filter with 300 mL of petroleum ether, and freeze-dry to obtain powdered sodium amine lignin sulfonate.

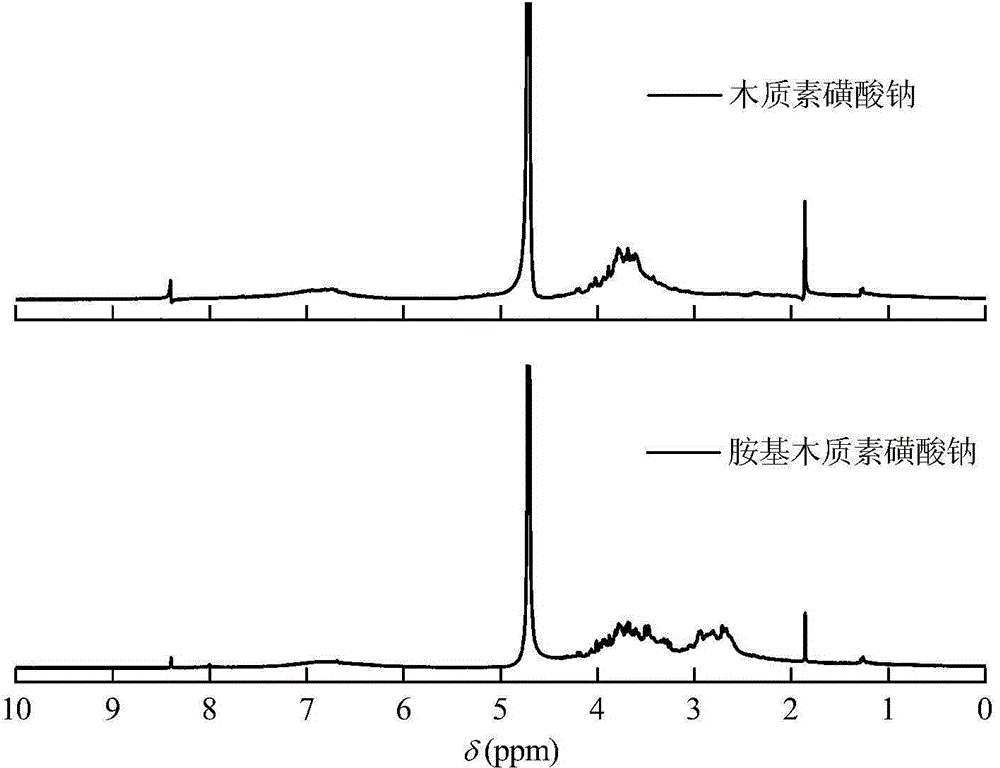

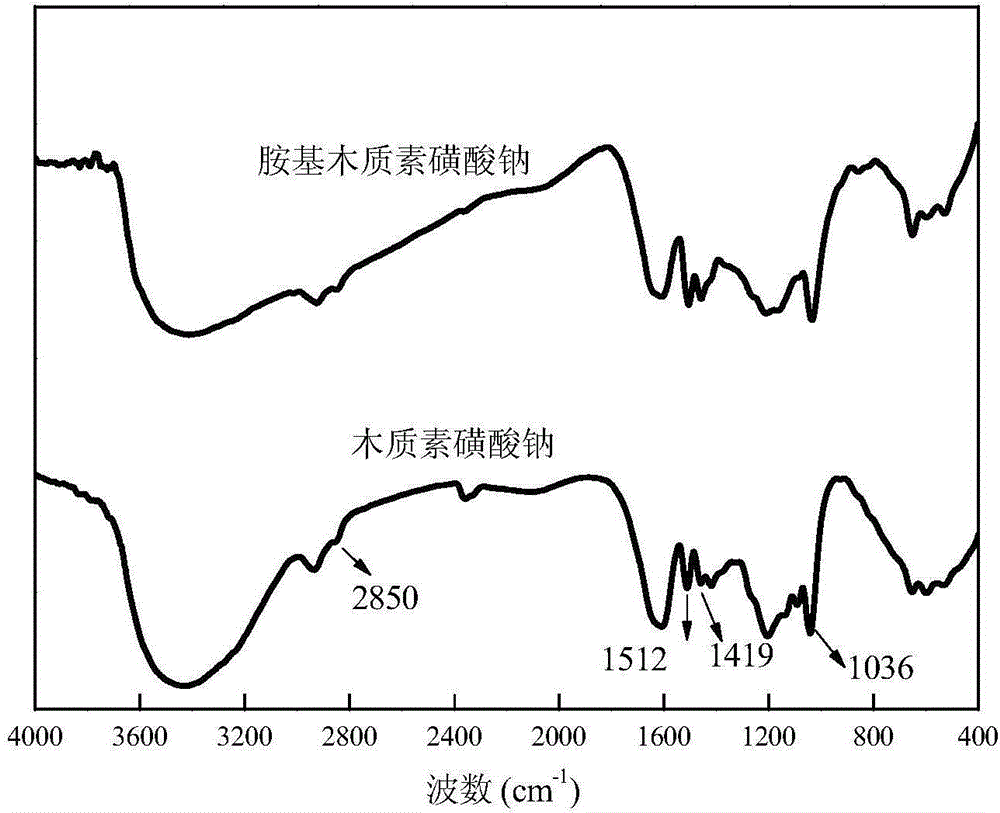

[0043] figure 1 It is the hydrogen nuclear magnetic spectrum of sodium lignosulfonate and sodium amine lignosulfonate. It can be clearly seen from the figure that compared with sodium lignosulfonate, sodium amine lignosulfonate weakens the aromatic proton peak at a chemical shift of 6.50-7.50ppm, and that at 2.50~3.00ppm is connected to the N element. The alkyl proton peak is significantly enhanced. This shows that the a...

Embodiment 2

[0057] (1) Dissolve 100g of sodium lignosulfonate in 150g of water, adjust the pH to 10, activate it in a 60℃ water bath for 1.0h, add 20g of triethylamine, slowly add 20g of acetaldehyde dropwise, finish the dropwise addition within 1h, and increase the temperature. To 80°C, continue to react for 2h to obtain sodium lignosulfonate solution;

[0058] (2) Extract the sodium amine lignosulfonate solution with 200 mL of methanol, wash and filter with 200 mL of petroleum ether, and freeze-dry to obtain powdered sodium amine lignin sulfonate.

Embodiment 3

[0060] (1) Dissolve 100g of sodium lignosulfonate in 200g of water, adjust the pH to 11, activate it in a 70℃ water bath for 1.0h, add 200g of diethylamine, slowly add 200g of propionaldehyde dropwise, the addition is complete within 1h, and the temperature rise To 90℃, continue to react for 3h to obtain sodium lignosulfonate solution;

[0061] (2) Extract the sodium amine lignosulfonate solution with 300 mL of propanol, wash and filter with 200 mL of petroleum ether, and freeze-dry to obtain powdered sodium amine lignin sulfonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com