Gradually-moulding bent tempered glass radian-changing device

A kind of equipment and glass technology, which is applied in the field of glass bending and arc-changing equipment to achieve the effect of saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

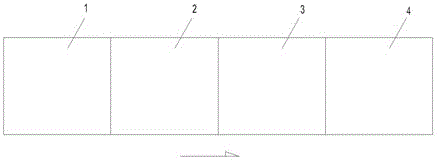

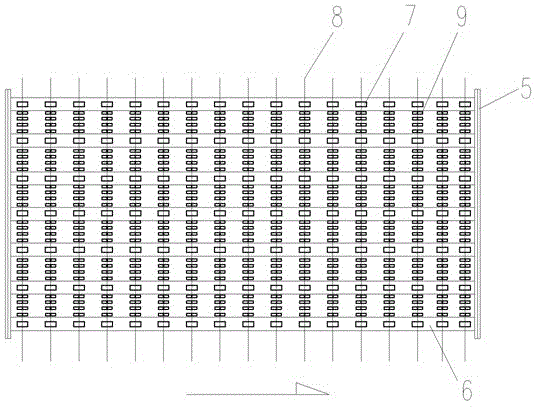

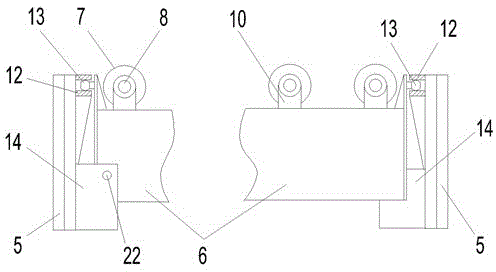

[0027] Such as figure 2 with image 3 Shown is a preferred embodiment of the curved tempered glass arc-changing device of the present invention. The direction of the arrow in the figure is the conveying direction of the glass. The arc-changing equipment includes several support beams 6 extending longitudinally and arranged at intervals in the transverse direction. A number of support seats 10 are longitudinally arranged, and support rollers 7 are installed on the support seats 10, and the support rollers 7 are horizontally connected in series by the flexible shaft 8, and the rotating flexible shaft 8 drives the support roller 7 to rotate, and the flexible shaft 8 is provided with an auxiliary Support wheel 9. The two ends of the support beam 6 are respectively connected to the two transverse arc-changing mechanisms 5 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com