A clamping device for optical fiber and lithium niobate wafer

A clamping device, lithium niobate technology, applied in the field of clamps, can solve the problems of large Fresnel reflection, strong noise optical signal, affecting the accuracy of the gyroscope, etc., and achieve the effect of stable clamping and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings.

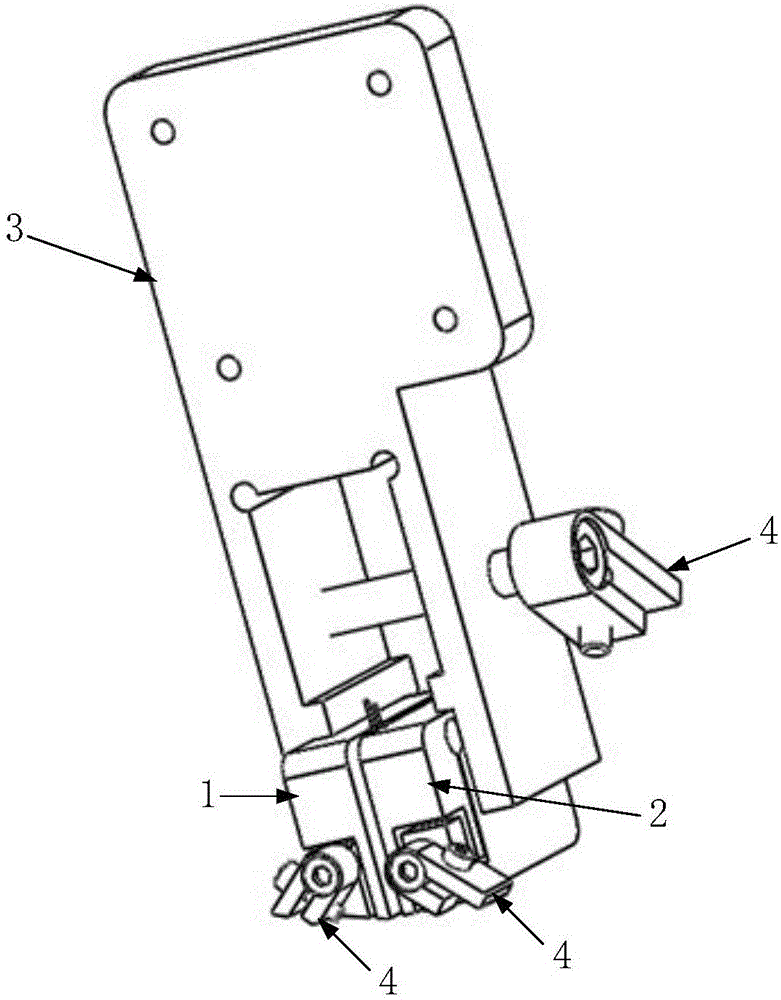

[0032] The optical fiber and lithium niobate wafer clamping device of the present invention comprises a left base 1, a right base 2, a base clamping member 3 and a locking mechanism 4, such as figure 1 shown.

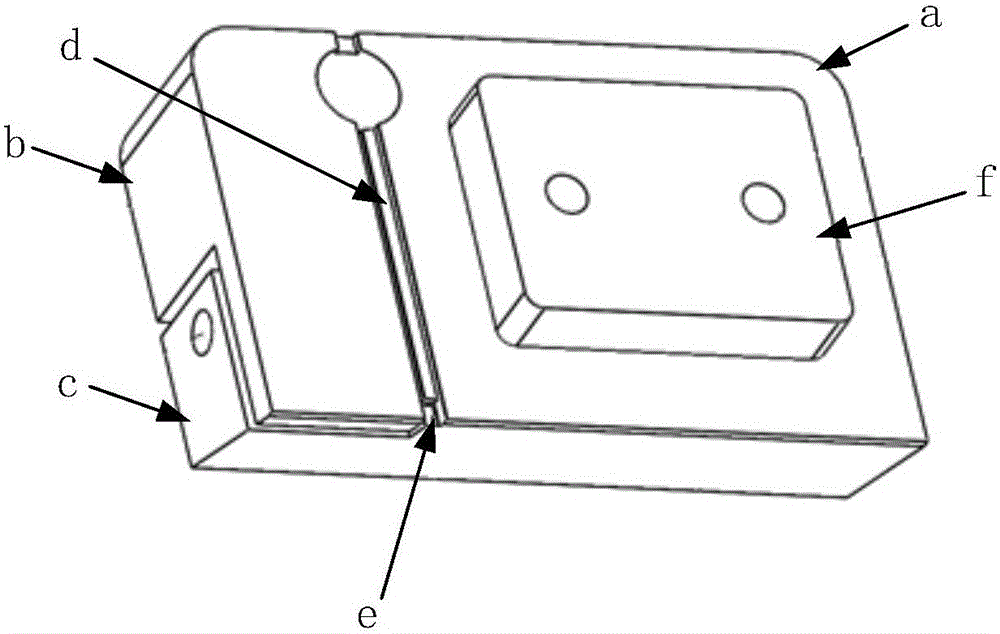

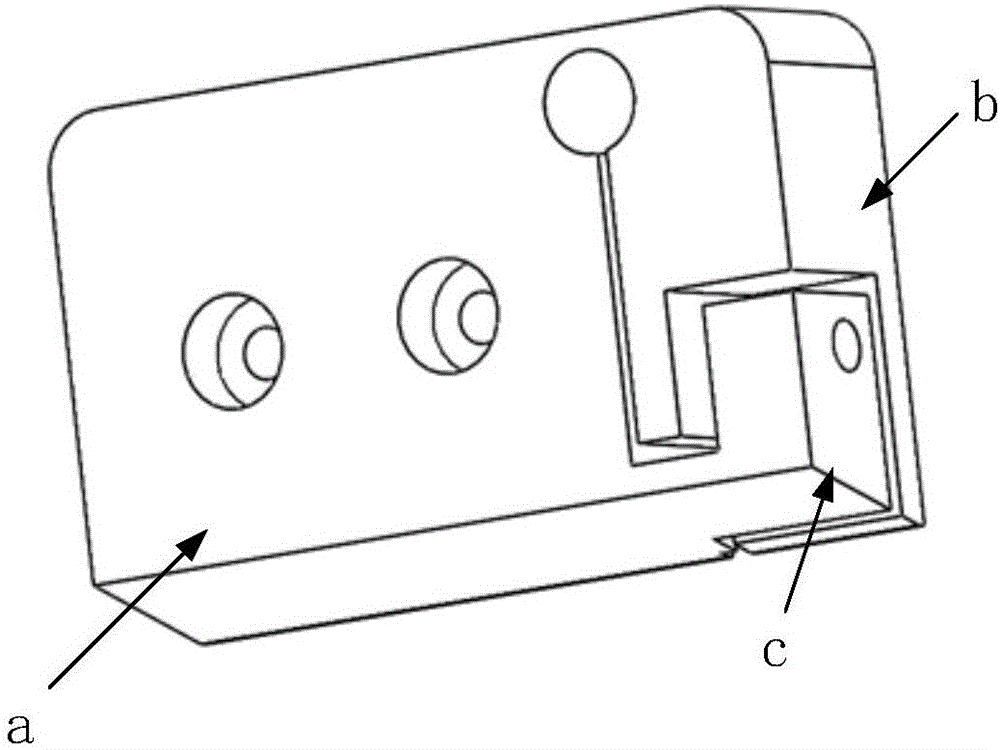

[0033] Among them, the left base 1 and the right base 2 are arranged symmetrically on the left and right, and are both an integrated rectangular block structure composed of a positioning block a, a clamping block b and a loading block c, and are made of AISI 321 annealed stainless steel.

[0034] Such as figure 2 , image 3 As shown, in the left base 1, the positioning block a is used as a non-deformable unit, and a rectangular protrusion f is designed on the right side, which is used to cooperate with the rectangular recess g designed on the left side of the positioning block a in the right base 2. The positioning between the left base 1 and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com