A linear anti-vibration, nonlinear anti-strong impact vibration isolator

An anti-vibration and non-linear technology, applied in the direction of shock absorber, shock absorber-spring combination, spring/shock absorber functional characteristics, etc., can solve the problem that the vibration isolator cannot achieve buffering and smooth rebound reset, which is not easy to achieve Abrasion and life-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

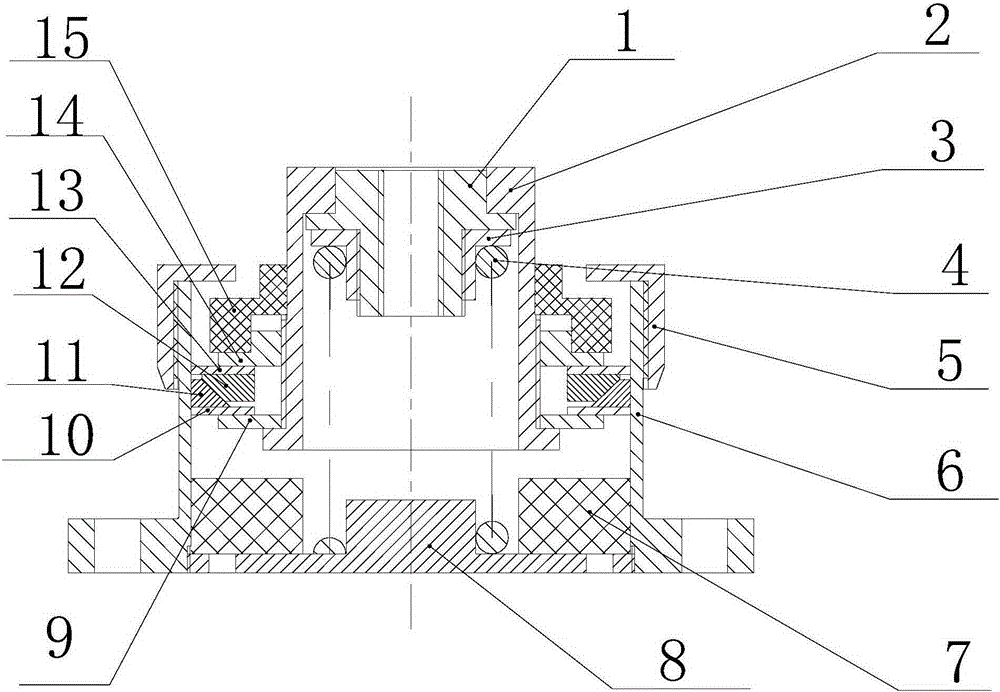

[0031] Embodiment one: if figure 1 As shown, a linear anti-vibration, nonlinear anti-strong shock type vibration isolator includes a mounting seat 6, a main shaft 2 that can move up and down and a lower spring seat 8 arranged at the bottom of the seat cavity are arranged in the seat cavity of the mounting seat 6 A main spring 4 for anti-vibration of the main shaft 2 is arranged between the main shaft 2 and the lower spring seat 8, and the main shaft 2 is supported in the seat cavity by the main spring 4.

[0032] The bottom end of the main shaft 2 radially protrudes to form a circle of retaining rings, which are located on the outer wall of the main shaft 2 above the retaining ring, and are arranged in sequence from bottom to top with a lower retaining ring 9, a damping friction ring 11, a damping pressure ring 12, an adjusting nut 14 and The upper buffer pad 15; the inner ring surface of the damping friction ring 11 has a tapered cavity structure with a wide top and a narrow ...

Embodiment 2

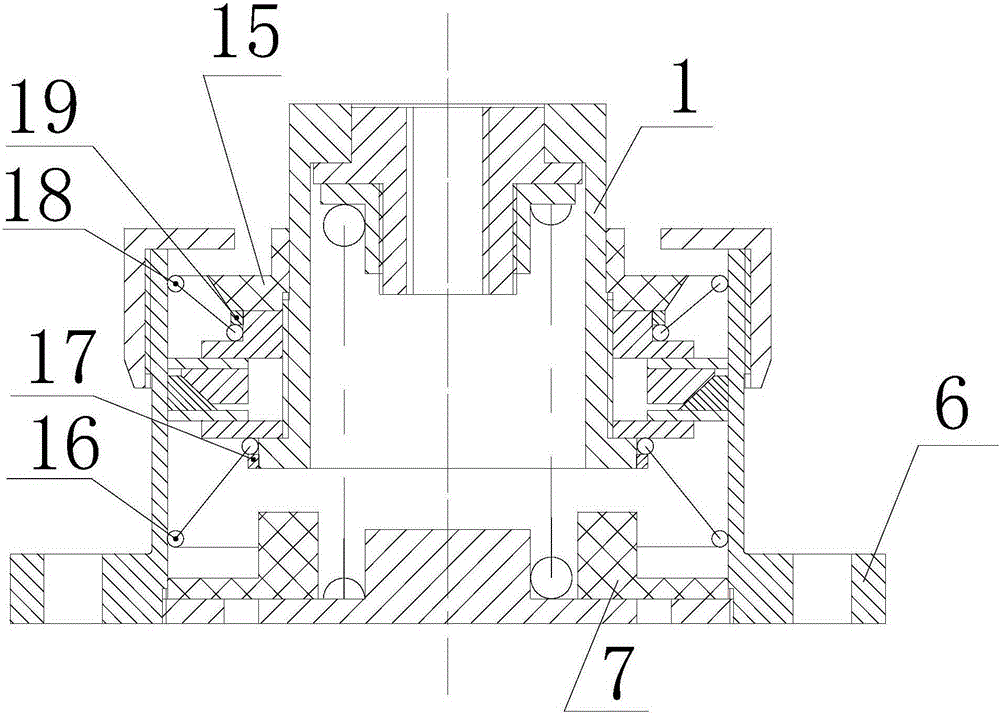

[0042] Embodiment two: if figure 2 As shown, a linear anti-vibration, nonlinear anti-strong impact type vibration isolator, the upper end of the lower buffer pad 7 is formed with a step, and a lower buffer cone spring 16 is arranged on the step, and the small ring end of the lower buffer cone spring 16 is connected to the The bottom end of the main shaft 1 is connected and fixed by the lower lock nut 17, and the large ring end of the lower buffer cone spring 16 is connected with the step on the lower buffer pad 7.

[0043] An upper buffer cone spring 18 is arranged on the adjustment nut 14, and the small ring end of the upper buffer cone spring 18 is arranged on the adjustment nut 14 through the upper lock nut 19, and the large ring end of the upper buffer cone spring 18 is against the inner wall of the seat cavity , so that when the main shaft 2 moves horizontally, the upper buffer conical spring 18 provides the reaction force of the nonlinear characteristic in the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com