A suction port structure of a flue gas wet treatment device

A technology of wet treatment and suction port, which is applied in the field of waste gas treatment devices, can solve problems such as the blockage of dust suction pipelines, the problem of dust accumulation in the collection wind hood, and the damage of hot presses, etc., to achieve the effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

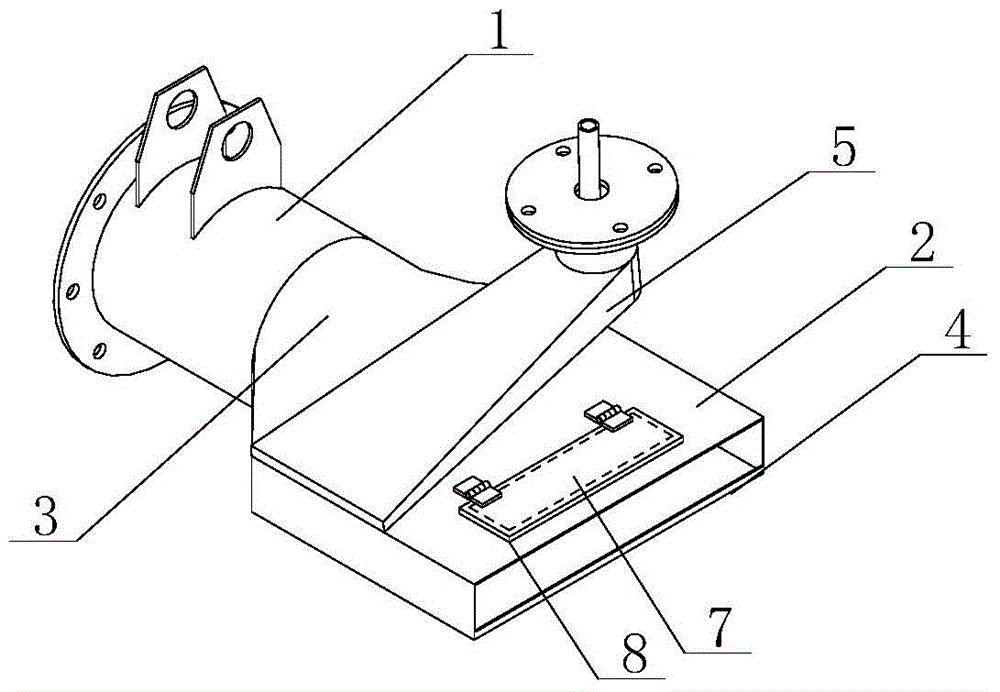

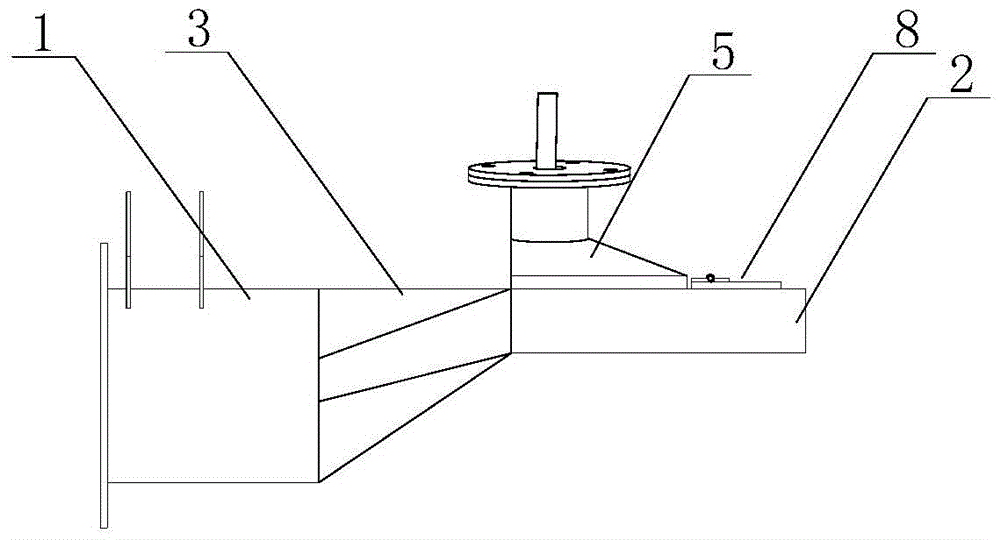

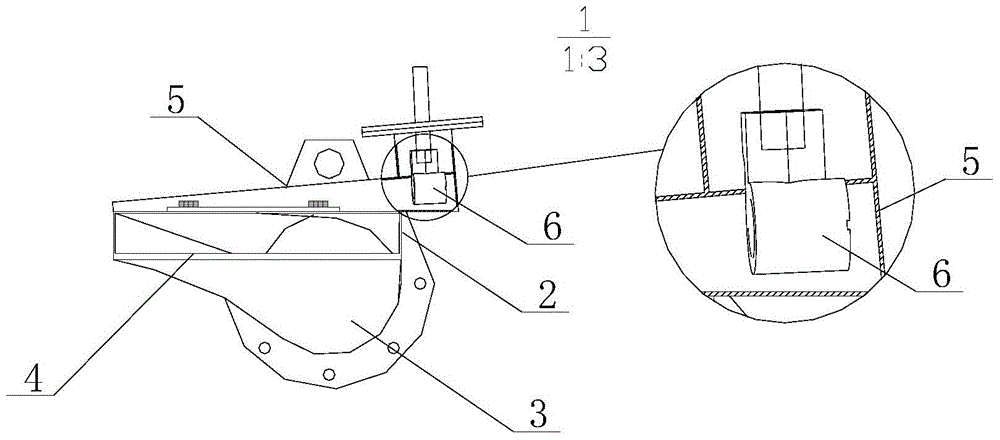

[0018] Such as Figure 1-3 As shown, a suction port structure of a flue gas wet treatment device is connected to the end of the dust suction pipeline 1 and includes a suction hood 2 and a connecting pipeline 3 connecting the suction hood 2 and the dust suction pipeline 1 .

[0019] The suction hood 2 is rectangular and has an air intake duct for horizontal air intake. The bottom surface of the air intake duct is higher than the bottom surface of the dust suction pipeline 1 . The bottom of the air inlet at the front end of the suction hood 2 is provided with a baffle 4 to prevent water from flowing out. The height of the baffle 4 is specifically between 1 / 7 and 1 / 6 of the height of the air inlet of the suction hood 2 . The top of the rear end of the suction hood 2 is provided with a spray hood 5 which communicates with it and protrudes upwards. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com