A method of co-producing allicin and black garlic powder with high antioxidant activity

A technology of oxidation activity and allicin, applied in the field of bioengineering, can solve the problem that allicin cannot be generated and utilized, and achieve the effect of ineffective utilization of allicin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

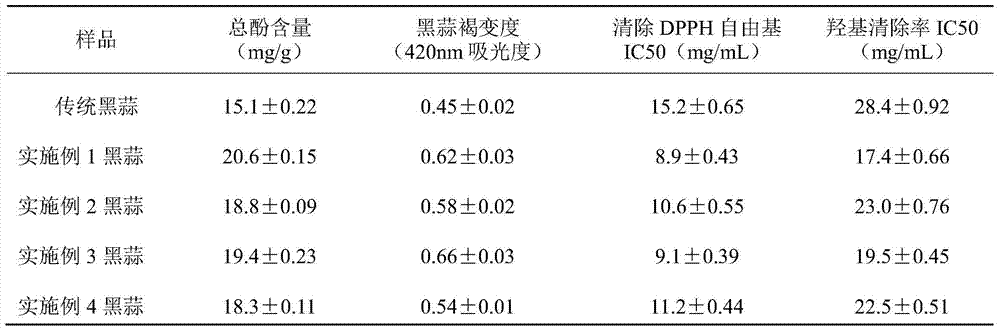

Embodiment 1

[0028] Garlic raw materials are peeled and crushed, left at room temperature for 30 minutes, allicin is extracted with supercritical carbon dioxide, extraction pressure is 20MPa, extraction temperature is 40°C, static extraction time is 15 minutes, dynamic extraction time is 90 minutes, and the yield of allicin is 0.76%. The extracted allicin was embedded in β-cyclodextrin to make allicin microcapsules. The embedding conditions were: allicin:β-cyclodextrin ratio 1:9 (w / w), temperature 30°C, time 1.5h. The garlic dregs that have extracted allicin are evenly added with glucose, 0.3% xylose (the total amount of reducing sugar added is 0.5%) and 0.3% lysine and 0.2% glycine (the total amount of added amino acid is 0.5%) that accounts for garlic quality. %), put into stainless steel trays, spread evenly, put into constant temperature and humidity box to ferment, the steps of fermentation are: 1) temperature 80 ℃, relative humidity 95%, fermentation 12h; 2) adjust the temperature of ...

Embodiment 2

[0062] Garlic raw materials are peeled and crushed, left at room temperature for 30 minutes, allicin is extracted with supercritical carbon dioxide, extraction pressure is 20MPa, extraction temperature is 40°C, static extraction time is 15 minutes, dynamic extraction time is 90 minutes, and the yield of allicin is 0.72%. The extracted allicin was embedded in β-cyclodextrin to make allicin microcapsules under the following conditions: the ratio of allicin:β-cyclodextrin was 1:9, the temperature was 30°C, and the time was 1.5h. Add 0.1% glucose (the total amount of reducing sugar is 0.1%) and 0.2% glycine, 0.1% alanine (the total amount of added amino acid is 0.3%) to the garlic dregs that have extracted allicin evenly, and put them into stainless steel trays, Spread evenly and ferment in a constant temperature and humidity box. The fermentation steps are: 1) temperature 75°C, relative humidity 90%, fermentation 18h; 2) adjust the temperature of the constant temperature and humid...

Embodiment 3

[0065]Garlic raw materials are peeled and crushed, left at room temperature for 30 minutes, allicin is extracted with supercritical carbon dioxide, extraction pressure is 20MPa, extraction temperature is 40°C, static extraction time is 15 minutes, dynamic extraction time is 90 minutes, and the yield of allicin is 0.81%. The extracted allicin was embedded in β-cyclodextrin to make allicin microcapsules under the following conditions: the ratio of allicin:β-cyclodextrin was 1:9, the temperature was 30°C, and the time was 1.5h. Add 0.2% glucose, 0.2% fructose (the total amount of reducing sugar added is 0.4%) and 0.3% glycine and 0.2% alanine (the total amount of added reducing sugar is 0.5%) evenly to the garlic dregs after extracting allicin, Put it into a stainless steel tray, spread it evenly, and put it into a constant temperature and humidity box for fermentation. The fermentation steps are: 1) temperature 85°C, relative humidity 80%, fermentation for 15h; 2) adjust the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com