Processing method of dried litchi chinensis

A processing method and dried lychee technology are applied in application, food preparation, food science, etc., which can solve the problems of inconvenient observation of appearance and color, unremoved lychee peel, and inconvenient eating, etc., so as to increase social and economic benefits and make lychees full of fragrance. , The effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

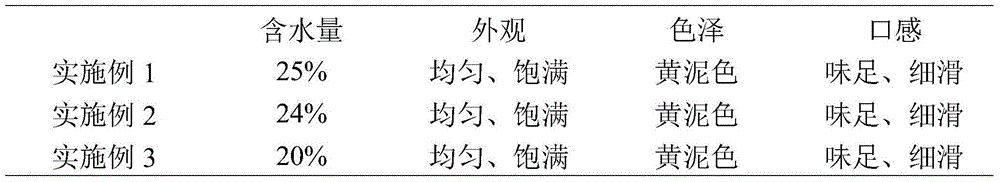

Embodiment 1

[0027] Embodiment 1, choose local ripe, fresh lychee 10Kg, and lychee flesh is thick, and core is little, is suitable for making lychee dry, does not process through filling, also can form after drying. After treatment, it has good plumpness and is in the shape of "lantern meat", with suitable sweet and sour, and full of lychee fragrance. Lychee pulp is obtained by washing, peeling, and pitting the lychees, and the lychee pulp is guaranteed to be intact and not damaged. To harden the lychee pulp, put the lychee pulp into 0.2% NaHSO 3 , 0.1% citric acid, 0.2% CaCl 2 Soak in the aqueous solution for 2 hours; the hardened lychee pulp can keep the shape in the subsequent saccharification and drying, and ensure the smooth processing of preserved fruit. To scald the hardened lychee pulp, put the hardened lychee pulp into hot water at 95°C for 3 minutes; take it out and drain at room temperature. Blanching can inactivate enzyme activity and prevent enzyme browning; stabilize or im...

Embodiment 2

[0028] Embodiment 2, choose local ripe, fresh lychee 10Kg, lychee flesh is thick, and core is little, is suitable for making lychee dry, does not process through filling, also can shape after drying. After treatment, it has good plumpness and is in the shape of "lantern meat", with suitable sweet and sour, and full of lychee fragrance. Lychee pulp is obtained by washing, peeling, and pitting the lychees, and the lychee pulp is guaranteed to be intact and not damaged. To harden the lychee pulp, put the lychee pulp into 0.2% NaHSO 3 , 0.1% citric acid, 0.2% CaCl 2 Soak in the aqueous solution for 2 hours; the hardened lychee pulp can keep the shape in the subsequent saccharification and drying, and ensure the smooth processing of preserved fruit. To scald the hardened lychee pulp, put the hardened lychee pulp into hot water at 90°C for 3 minutes; take it out and drain at room temperature. Blanching can inactivate enzyme activity and prevent enzyme browning; stabilize or impro...

Embodiment 3

[0029] Embodiment 3, choose local ripe, fresh lychee 10Kg, lychee flesh is thick, and core is little, is suitable for making lychee dry, does not process through filling, also can form after drying. After treatment, it has good plumpness and is in the shape of "lantern meat", with suitable sweet and sour, and full of lychee fragrance. Lychee pulp is obtained by washing, peeling, and pitting the lychees, and the lychee pulp is guaranteed to be intact and not damaged. To harden the lychee pulp, put the lychee pulp into 0.2% NaHSO 3 , 0.1% citric acid, 0.2% CaCl 2 Soak in the aqueous solution for 2 hours; the hardened lychee pulp can keep the shape in the subsequent saccharification and drying, and ensure the smooth processing of preserved fruit. Put the hardened lychee pulp into 95°C, 1% NaCl hot water for 2 minutes; take it out and drain at room temperature. Blanching can inactivate enzyme activity and prevent enzyme browning; stabilize or improve color; reduce the number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com