Liquid-cooling iron-coreless permanent-magnet linear motor

A permanent magnet linear motor, liquid cooling technology, applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of large primary loss, small rated thrust, and poor continuous output capability of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

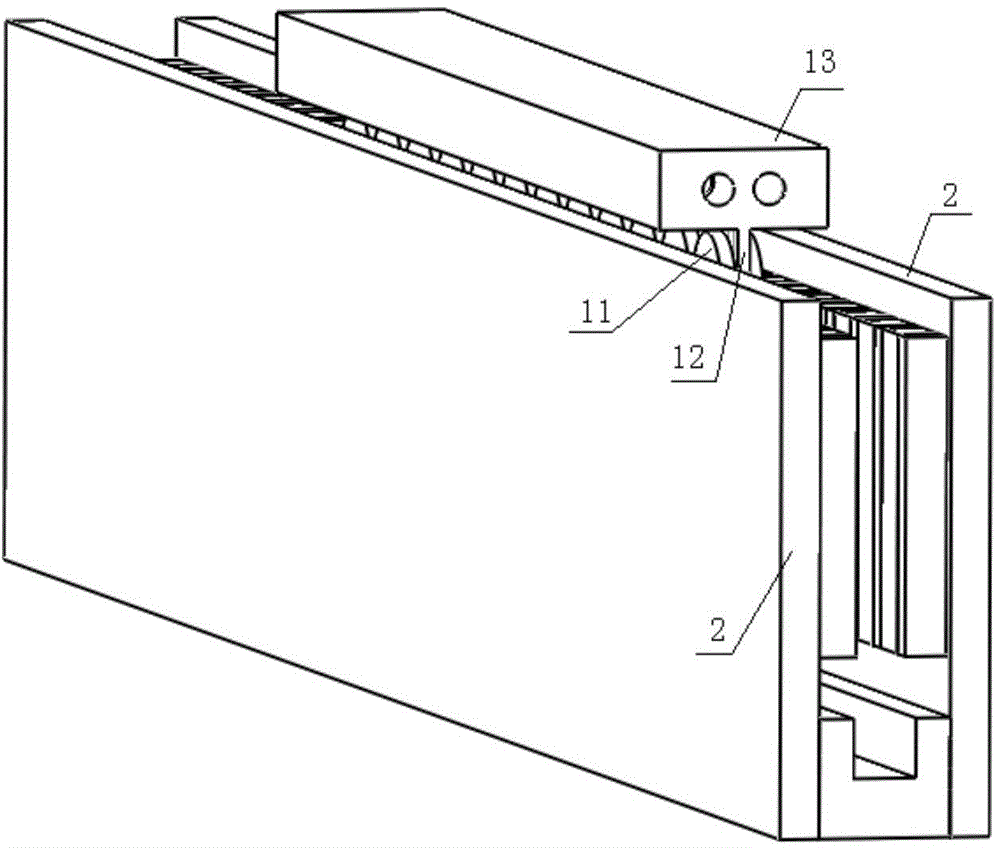

[0031] Specific implementation mode one: combine Figure 1 to Figure 3 ,as well as Figure 9 To illustrate this embodiment, the liquid-cooled coreless permanent magnet linear motor described in this embodiment includes a primary 1 and a secondary;

[0032] The primary includes a primary winding 11, a fixed plate 12 and a thrust output plate 13. The primary winding 11 is composed of 2km racetrack-shaped coils, wherein k is a positive integer, and m is the phase number of the motor; the fixed plate 12 is flat, and the primary winding 11 2km coils are symmetrically arranged on both sides of the fixed plate 12; the thrust output plate 13 is fixedly connected to one end of the fixed plate 12 along the moving direction;

[0033] The secondary is a bilateral structure, each secondary 2 includes a secondary iron core and a permanent magnet, the bilateral secondary 2 is arranged on both sides of the primary, and forms a series magnetic circuit, and two air gaps are formed between the ...

specific Embodiment approach 2

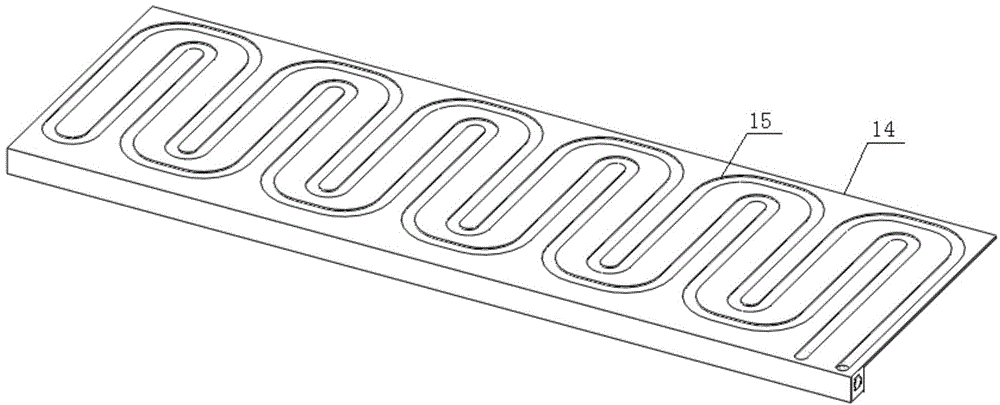

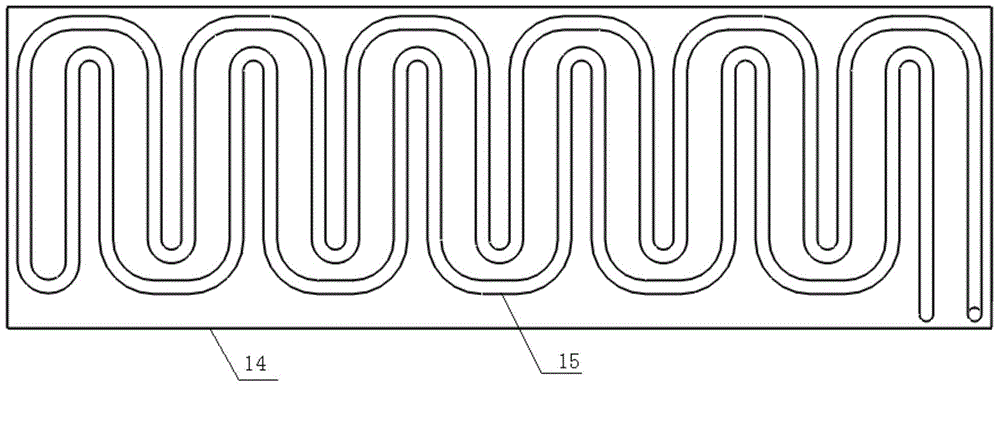

[0036] Specific implementation mode two: combination Figure 4 and Figure 5 This embodiment is described. This embodiment is a further limitation of the liquid-cooled coreless permanent magnet linear motor described in Embodiment 1. In this embodiment, the cooling liquid passage 15 is a parallel double-channel structure.

[0037] In this embodiment, dual-channel parallel cooling liquid channels are used to increase the contact area between the cooling liquid and the fixed plate 12 and improve the cooling effect.

specific Embodiment approach 3

[0038] Specific implementation mode three: combination combination Figure 6 and Figure 7 This embodiment is described. This embodiment is a further limitation of the liquid-cooled coreless permanent magnet linear motor described in Embodiment 2. In this embodiment, the primary winding 11 is dipped in paint and potted with epoxy resin.

[0039] In the coreless permanent magnet linear motor with natural cooling, the primary winding 11 is directly arranged on the fixed plate without cooling channels, or it is directly potted with epoxy resin without the fixed plate. The former has poor thermal conductivity, and the latter Poor strength. However, in this embodiment, the primary winding 11 is arranged on both sides of the fixing plate 12, dipped in paint, and then potted with epoxy resin with good thermal conductivity and high structural strength, so as to fix the primary winding 11 on the fixing plate 12. This structure At the same time, it has high strength and high thermal c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com