Method for measuring thickness of transparent spherical cavity container

A measurement method, spherical technology, applied in the field of optical measurement, can solve problems that are not easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

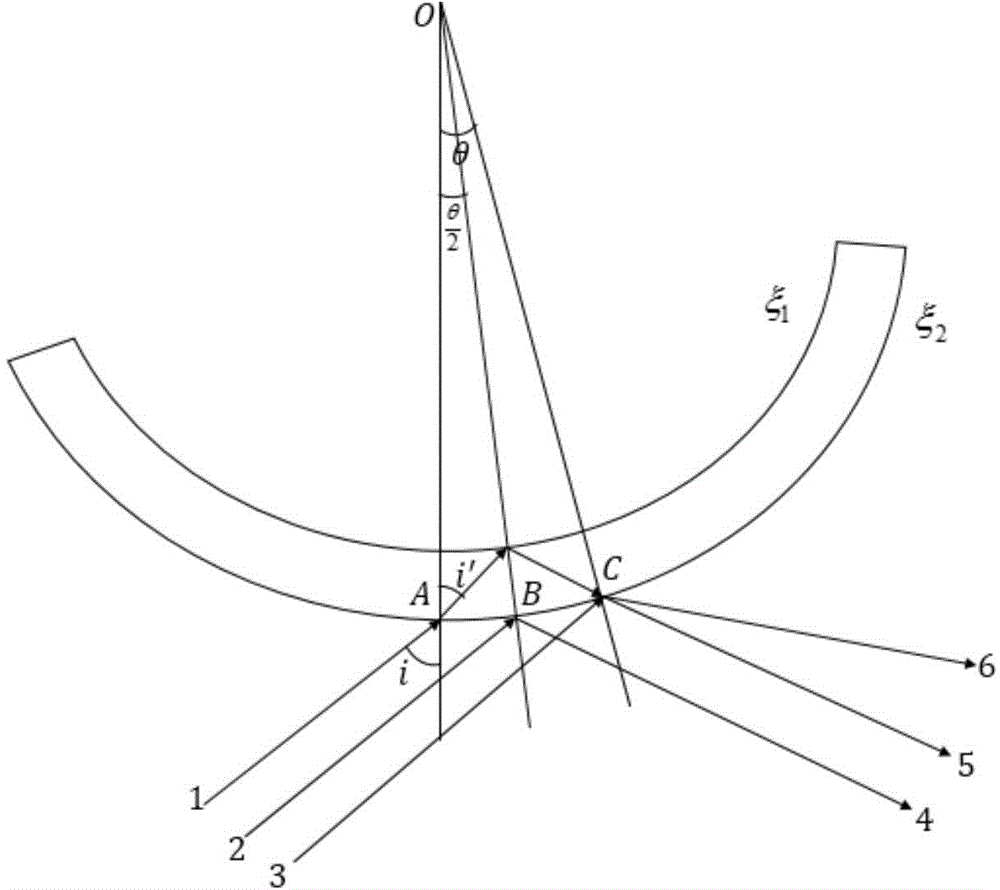

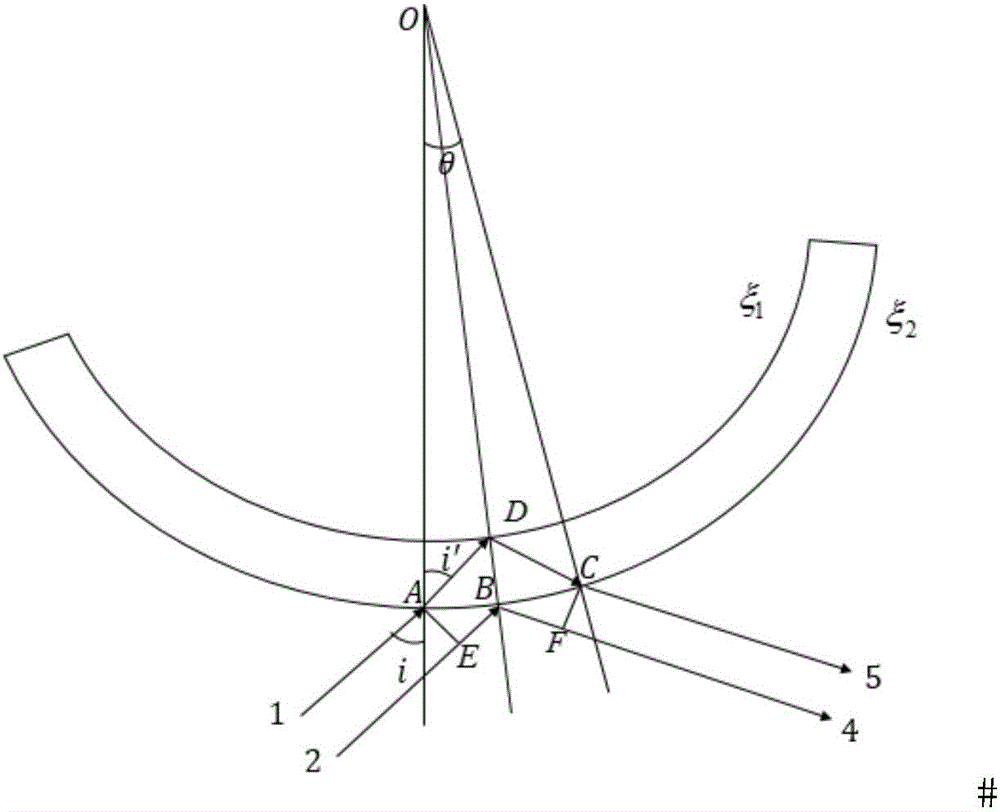

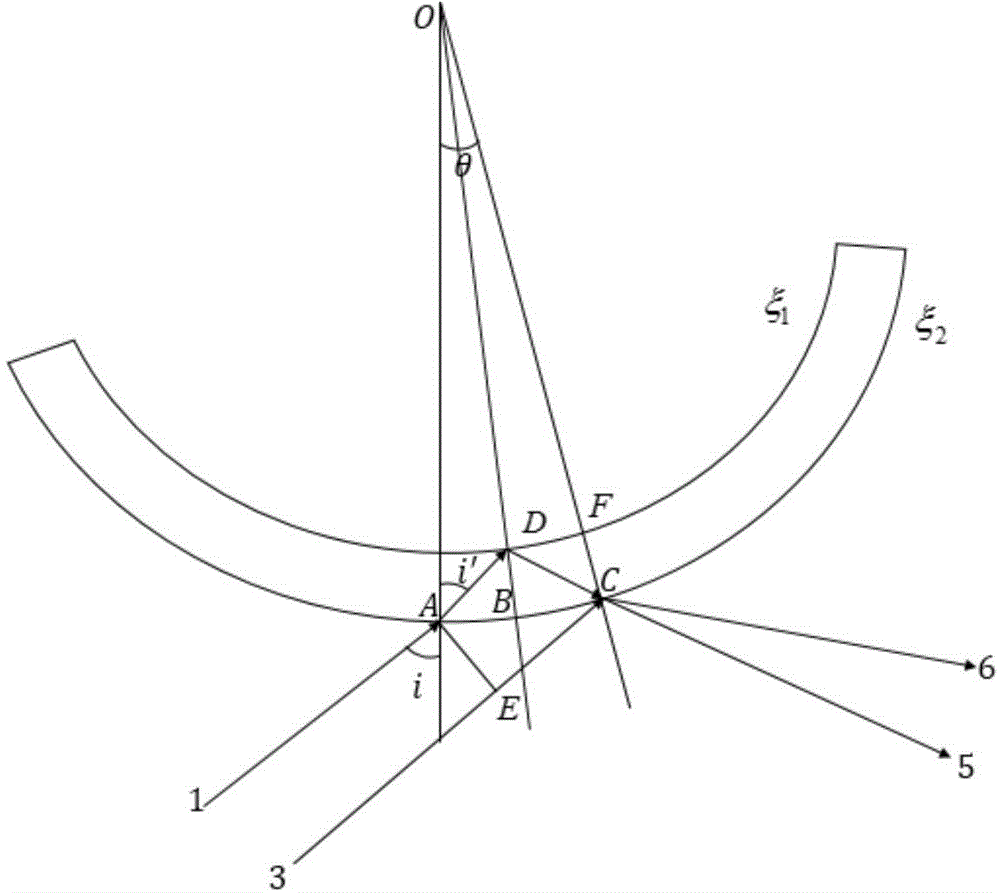

[0027] Such as figure 1 As shown, ξ 1 is the inner surface of the container, ξ 2 for the outer surface of the container. Incident rays 1, 2, 3 represent incident laser beams. Since the directionality of the laser is very good, it can be considered theoretically that the incident rays 1, 2, and 3 are parallel rays. OA, OB, OC are the normals of different incident positions on the inner and outer surfaces of the container. The refractive index of the dielectric layer is n. The incident light 1 enters the medium layer after being refracted by the outer surface, and is refracted from the outer surface after being reflected by the inner surface to form an outgoing light 5 . The incident ray 2 is reflected by the outer surface of the container as reflected ray 4 . Incident light 3 becomes reflected light 6 after being reflected by the outer surface.

[0028] The angle between the incident ray 1 and the normal OA is i, that is, the incident angle is i, and the refraction angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com