Method for online repair of regenerative burner nozzle of heating furnace

A repair method, a regenerative technology, applied in the direction of lining repair, etc., can solve the problem that the burner spout repair problem has not been effectively solved, increase the maintenance cost of the heating furnace, prolong the maintenance cycle of the heating furnace, etc., to shorten the maintenance period, Reduce maintenance costs and production costs, the effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

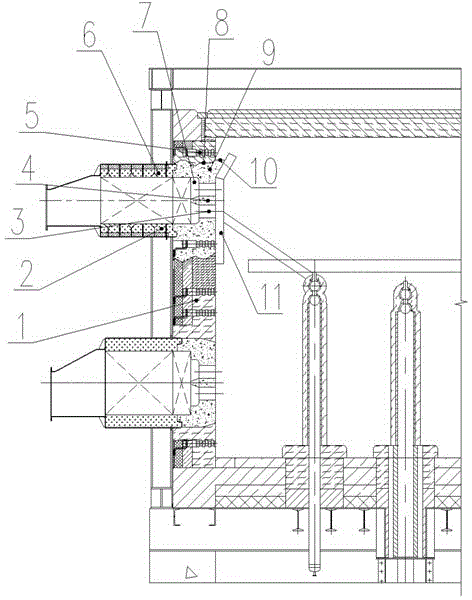

[0029] Taking the repair of double regenerative burners 2 of a regenerative heating furnace as an example, this method will be described in detail below.

[0030] A blast furnace gas double regenerative slab heating furnace, the rated gas flow rate of the regenerative burner 2 is 4500Nm 3 / h, when repairing the regenerative burner 2, use the following steps:

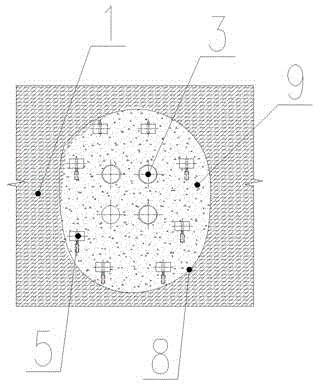

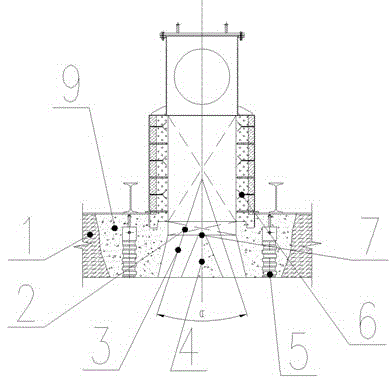

[0031] The first step is to remove the burner nozzle in the original regenerative burner and the furnace wall around the original burner nozzle, retain the regenerative burner shell 6, and retain the original furnace wall 1 after dismantling. Some tapered mouths 8, that is, the original bell mouth, the shape of the tapered mouth 8 is characterized by a large inside and a small outside. The small opening side of the corresponding to furnace wall 1.

[0032] The second step is to design and calculate the shape and size of the nozzle 3 of the regenerative burner according to the heat supply capacity of the regenerative bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com