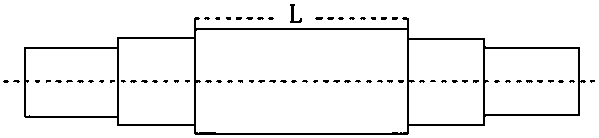

Threaded rod compressor broken main shaft burying shaft repairing method

A screw compressor and repair method technology, applied in the field of mechanical spindle repair, can solve the problems of long spindle customization time, wear and tear, and long production recovery period of enterprises, so as to reduce the loss of spindle scrap, the repair method is simple, and the reuse is realized. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following examples may enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the examples.

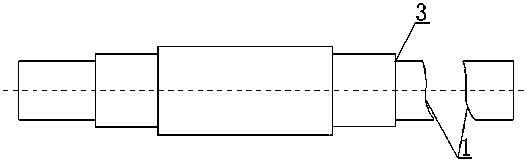

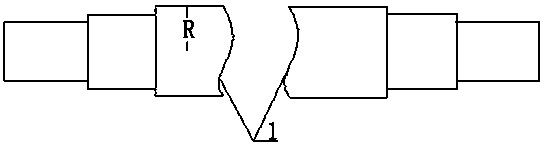

[0033] according to Figure 1-8 A screw compressor fracture main shaft buried shaft repair method, comprising the following steps:

[0034] Step 1: Clamp and position one section of the broken main shaft with the P end of the positioning tool 6, and then clamp and position the connecting shaft and the positioning tool 6;

[0035] Step 2: Push the Q end to make the connecting shaft and the broken main shaft installed and clamped on the P end complete the cooperation;

[0036] Step 3: Perform spot welding on the combined surface of the fractured shaft and the connecting shaft, that is, spot weld the first spot welding part;

[0037] Step 4: After the spot welding of the first spot welding position is completed, wait for the spot welding position to cool down to room temperature, loos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com