Downhole torque control tool for milling operation

A technology of torque control and operation well, which is applied in wellbore/well components, earthwork drilling and production, etc. It can solve the problems of difficult wellhead operation, large loss of efficiency pipe string, and pipe string tripping, etc., so as to improve the stability of drilling and grinding , improve the milling efficiency and avoid the fluctuation of drilling pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

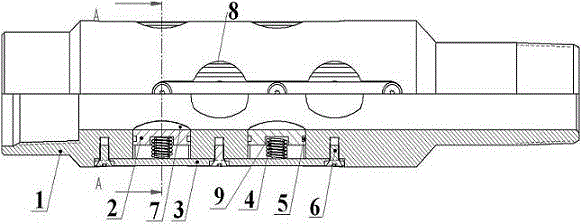

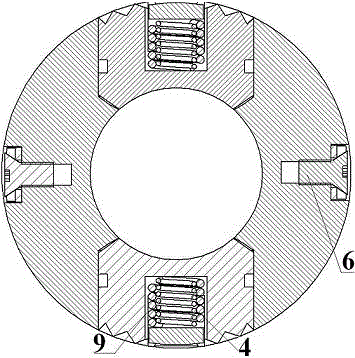

[0022] This embodiment provides a downhole torque control tool for grinding and milling operations, which includes a body 1, which is a tubular body with a through hole 7 in the circumferential direction, and a torque anchor that is clearance-fitted with the through hole 7 is provided in the through hole 7 Claw 2, the torque anchor fluke 2 is perpendicular to the axial direction of the body 1, the anchoring end of the torque anchor fluke 2 is provided with an anchor tooth 8 parallel to the axial direction of the body 1 and a counterbore 9, and the counterbore 9 is provided with A telescopic spring 4, the lower end of the telescopic spring 4 is provided with a pressing plate 3, and the pressing plate 3 is fixedly connected with the body 1;

[0023] The size of the other end of the torque fluke 2 is larger than the inner diameter of the top of the through hole 7 .

[0024] The specific working process of the downhole torque control tool for milling operation provided in this emb...

Embodiment 2

[0028] On the basis of embodiment 1, this embodiment provides a kind of figure 1 In the downhole torque control tool for milling operation shown, the through hole 7 is a frustum-shaped through-hole with a necking step, and the inner diameter of one end of the frusto-conical through-hole near the center of the body 1 is smaller than the other end;

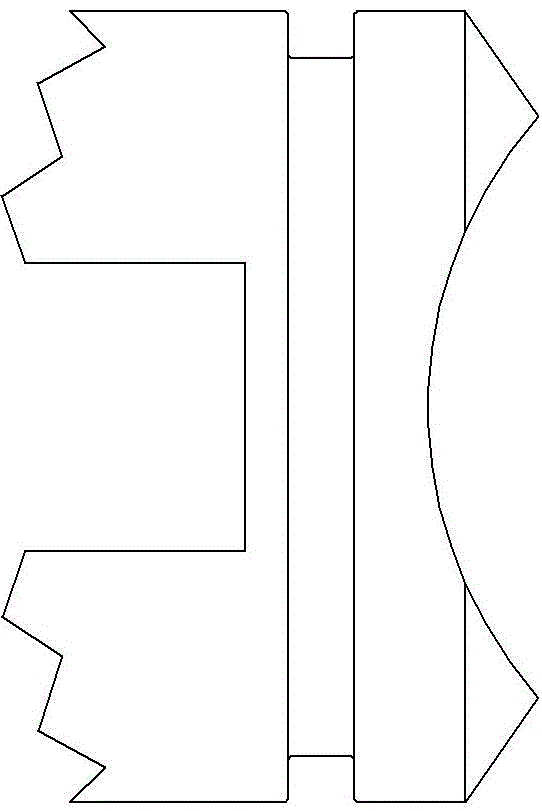

[0029] Such as figure 2 , image 3 As shown, the torque fluke 2 is cylindrical, and the radius of the anchoring end of the torque fluke 2 is larger than the inner diameter of the end of the frustum-shaped through hole near the center of the body 1, and is not larger than the inner diameter of the other end of the frustum-shaped through hole, that is, the two ends of the torque fluke 2 Both are arc-shaped, and the center of the anchor end is provided with a counterbore 9 for placing the telescopic spring 4 and a horizontal anchor tooth along the axial direction of the body 1 .

[0030] In this embodiment, the body 1 is a hollow tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com