Refrigerator handle and manufacturing method thereof

A technology for handles and refrigerators, which is applied in the direction of wing leaf handles, wing leaf ball handles, and door/window accessories. Strong, long-term use, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further elaborated below in conjunction with the accompanying drawings.

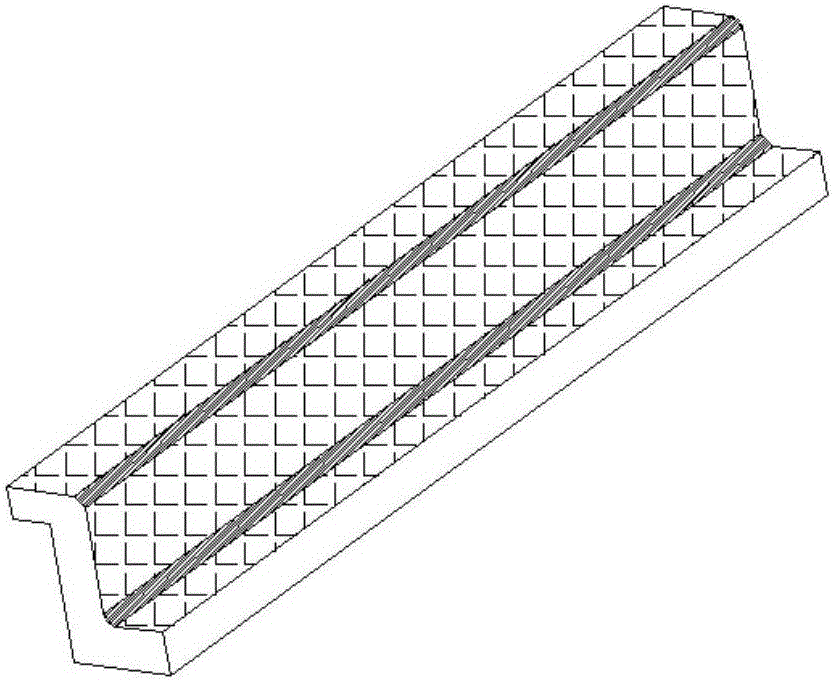

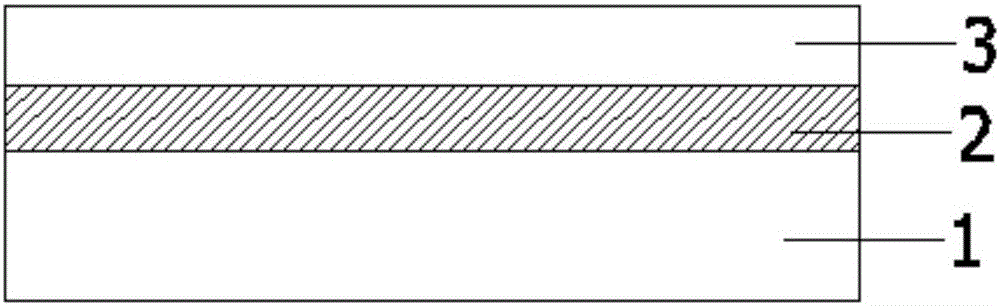

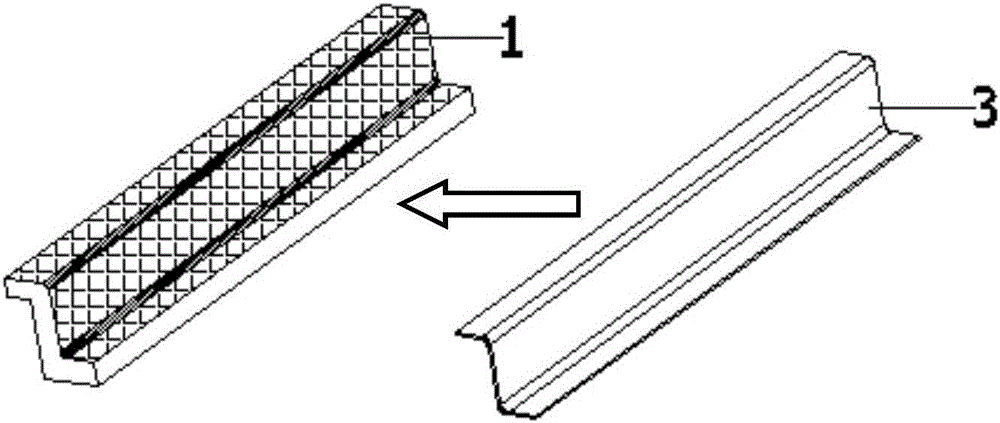

[0033] Such as Figure 1-3 A refrigerator handle is shown, which is mainly composed of a refrigerator handle base material 1, an adhesive layer 2 and a natural material layer 3, and the refrigerator handle base material 1 is fixedly connected with the natural material layer 3 through the adhesive layer 2. Refrigerator handle substrate 1 is made of ABS plastic, HIPS plastic or other plastics, and can also be made of aluminum alloy or stainless steel. The adhesive layer 2 is glue or tape, and the natural material layer 3 is made of bark or bamboo skin. production.

[0034] According to an embodiment of the present invention, the refrigerator handle substrate 1 is made of ABS plastic, HIPS plastic or other plastics.

[0035] A method for manufacturing a refrigerator handle, comprising the steps of:

[0036] Step 1, Refrigerator handle substrate molding

[0037] Plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com