Preparation method for papaya fruit vinegar and application thereof

A technology of papaya and melon fruit, which is applied in the field of papaya fruit vinegar preparation, can solve the problems of reducing the use value and economic value of papaya, affecting the enthusiasm and income of papaya planting, and the inability to form industrialized processing, etc., to regulate blood pressure , improve transparency, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

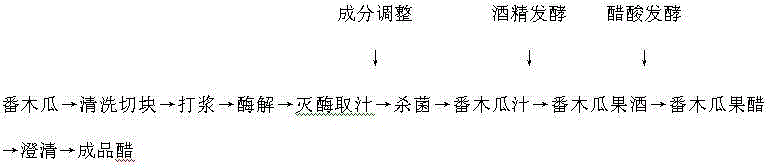

[0048] A preparation method of papaya fruit vinegar, comprising the following steps:

[0049] (1) Raw material selection: choose mature papaya as raw material, and remove rot, pests and diseases;

[0050] (2) Beating: put the selected papaya pulp into a beater for beating;

[0051] (3) Enzyme treatment: adjust the pH to 3.5 with citric acid, add 0.08% pectinase, and keep warm in a constant temperature water bath at 50-55°C for 2 hours;

[0052] (4) Enzyme-inactivating juice extraction: keep the enzyme-treated papaya juice in a constant temperature water bath at a temperature of 90°C for 10 minutes to achieve the purpose of inactivating the enzyme. After inactivating the enzyme, filter it with gauze to obtain the filtrate;

[0053] (5) Ingredient adjustment: Add white sugar to the filtrate to make the soluble solids (TSS) in the papaya filtrate 14°Bix, and the TSS content of the papaya itself is 5°Bix. It is necessary to add white sugar to make the papaya wine The sugar conte...

Embodiment 2

[0066] Other content is as embodiment 1, a kind of preparation method of papaya fruit vinegar, comprises the following steps:

[0067] (1) Raw material selection: choose mature papaya as raw material, and remove rot, pests and diseases;

[0068] (2) Beating: beat the papaya pulp into a pulp;

[0069] (3) Enzyme treatment: add citric acid to papaya pulp, adjust the pH to 3, then add 0.06% pectinase, and keep warm in a constant temperature water bath at 50°C for 2 hours;

[0070] (4) Enzyme-inactivated juice extraction: keep the enzyme-treated papaya pulp in a constant temperature water bath at a temperature of 85°C for 8 minutes, and then filter to obtain the filtrate;

[0071] (5) Composition adjustment: add white sugar to the filtrate to make the soluble solids in the papaya filtrate 13°Bix;

[0072] (6) Sterilization standby: sterilize for 15 seconds at a temperature of 90°C, and add 0.04% sodium erythorbate;

[0073] (7) Alcohol fermentation: inoculate the yeast seed liq...

Embodiment 3

[0078] Other content is as embodiment 1, a kind of preparation method of papaya fruit vinegar, comprises the following steps:

[0079] (1) Raw material selection: choose mature papaya as raw material, and remove rot, pests and diseases;

[0080] (2) Beating: beat the papaya pulp into a pulp;

[0081] (3) Enzyme treatment: add citric acid to papaya pulp, adjust the pH to 4, then add 0.11% pectinase, and keep warm in a constant temperature water bath at 55°C for 2 hours;

[0082] (4) Enzyme-inactivated juice extraction: keep the enzyme-treated papaya pulp in a constant temperature water bath at a temperature of 95°C for 12 minutes, and then filter to obtain the filtrate;

[0083] (5) Composition adjustment: add white sugar to the filtrate to make the soluble solids in the papaya filtrate 13°Bix;

[0084] (6) Sterilization for standby: sterilize for 30 seconds at a temperature of 98°C, and add 0.07% sodium erythorbate;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com