Preparing method of novel composite compatilizer

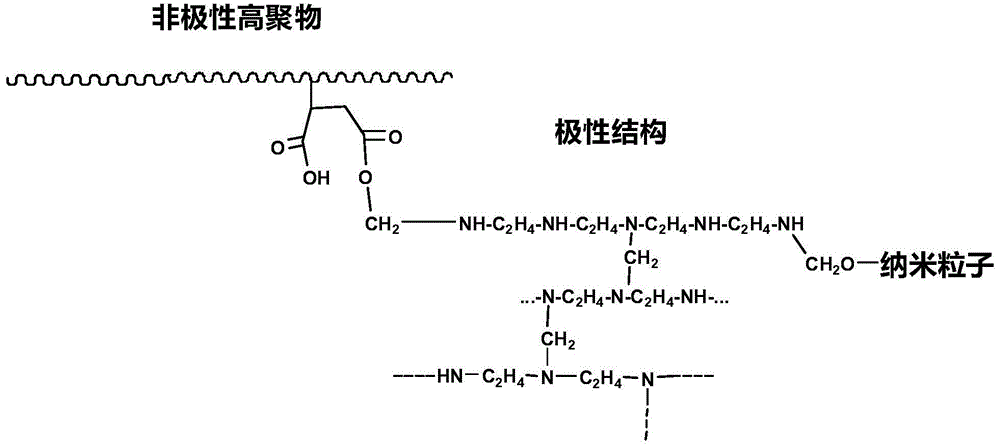

A composite and compatibilizer technology, applied in the field of polymer blending compatibilizers, new composite compatibilizers and their preparation, can solve the problem of phase separation of incompatible blending systems, which is difficult to In order to achieve the effects of selective distribution, changing phase morphology and reducing interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

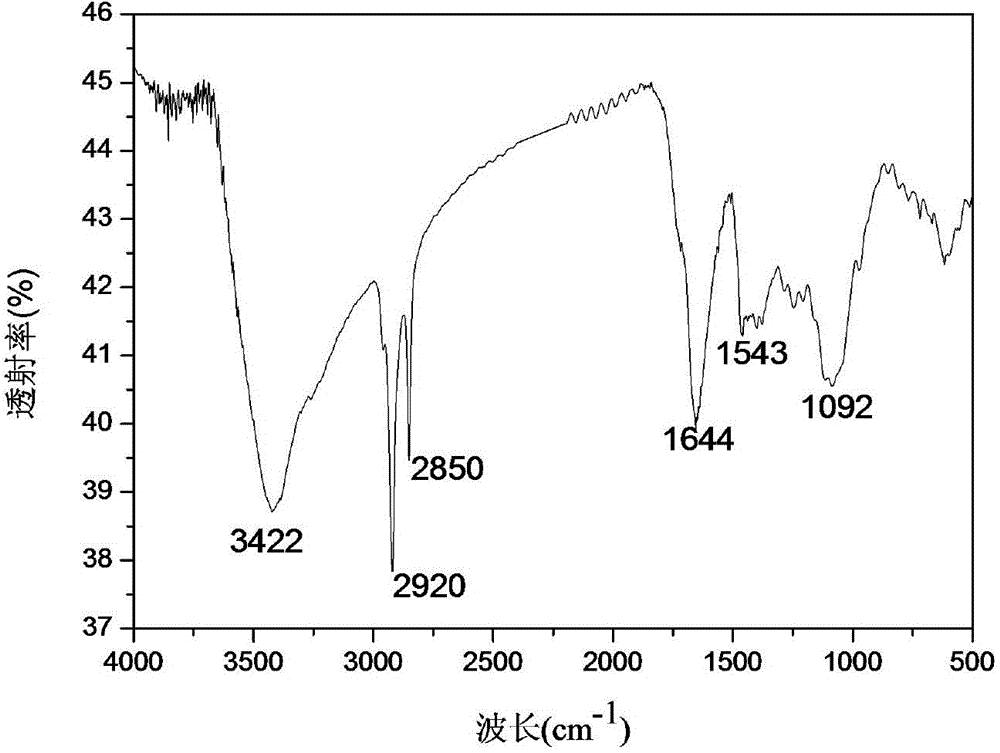

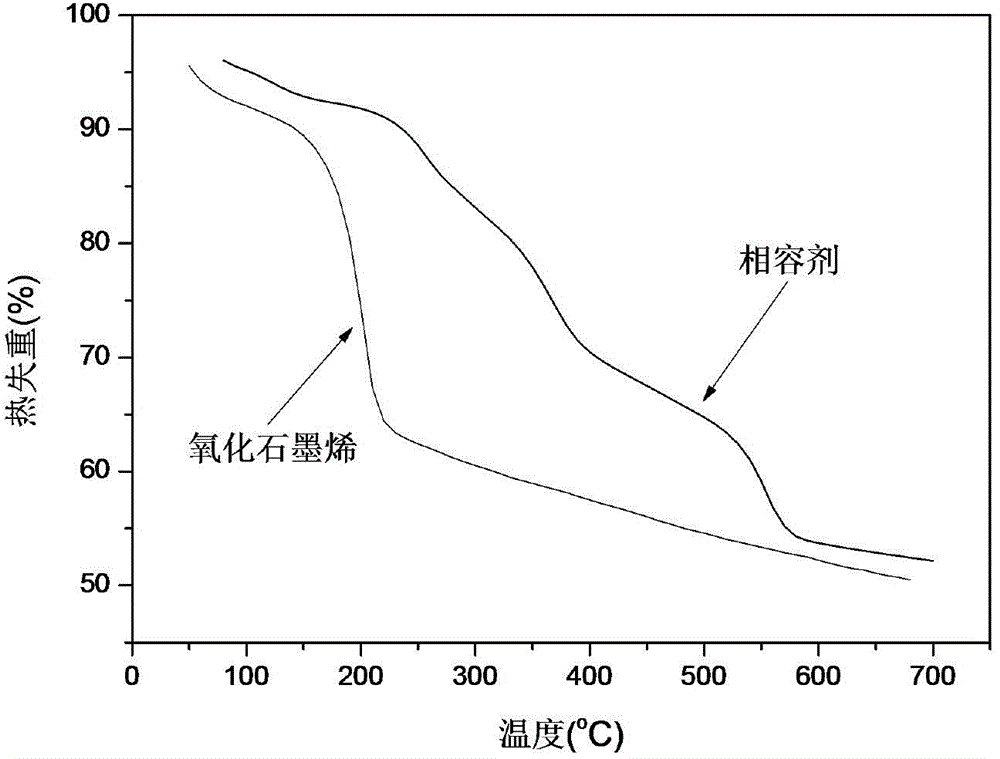

Method used

Image

Examples

Embodiment 1

[0025] (1) Add glycidyltrimethylammonium bromide to a graphene oxide aqueous solution with a concentration of 1.03 g / L until the solution becomes clear and transparent, and react at room temperature for 1 hour. The obtained flocculent precipitate was filtered, washed and dried to obtain intermediate 1. Wherein, the addition amount of glycidyltrimethylammonium bromide is 2.84g / L graphene oxide aqueous solution.

[0026] (2) Add 9.2 g of 37% to 40% formaldehyde solution (containing 0.11 mol of formaldehyde) dropwise into a reactor containing 0.04 mol of tetraethylenepentamine, and react at 30° C. for 2.5 hours. Raise the temperature to 150°C, react for 2 hours, cool down to 90°C, and distill under reduced pressure (at a pressure of 0.07-0.95MPa) for about 1 hour to obtain Intermediate 2.

[0027] (3) Mix 2.0g high-density polyethylene grafted maleic anhydride and 8.0g intermediate 2 in 50ml xylene, heat up to 120°C, react for 4 hours, remove excess intermediate 2 by filtration,...

Embodiment 2

[0035] (1) Add epoxypropyltripropylammonium chloride to a carbon nanotube aqueous solution with a concentration of 2.04g / L (carbon nanotubes are purchased directly, with a particle size of 2-30nm), until the solution becomes clear and transparent, and react at room temperature 2 hours. The obtained flocculent precipitate was filtered, washed and dried to obtain intermediate 1. Wherein, the addition amount of glycidyltripropylammonium chloride is 4.14g / L carbon nanotube aqueous solution.

[0036] (2) Add 6.9 g of 37% to 40% formaldehyde solution (containing 0.09 mol of formaldehyde) dropwise into a reactor containing 0.09 mol of decanediamine, and react at 30° C. for 2 hours. Raise the temperature to 155°C, react for 3 hours, cool down to 90°C, and distill under reduced pressure (at a pressure of 0.07-0.95MPa) for 1 hour to obtain Intermediate 2.

[0037](3) Mix 5g of ultra-high molecular weight polyethylene grafted maleic anhydride with 15g of intermediate 2 in 165ml of xyle...

Embodiment 3

[0040] (1) Glycidyltrimethylammonium chloride was added to a graphene oxide aqueous solution with a concentration of 1.45g / L until the solution became clear and transparent, and reacted at room temperature for 0.5 hours. The obtained flocculent precipitate was filtered, washed and dried to obtain intermediate 1. Wherein, the concentration of glycidyltrimethylammonium chloride final addition amount is 3.54g / L graphene oxide aqueous solution.

[0041] (2) Add 26 g of 37% to 40% formaldehyde solution (containing 0.32 mol of formaldehyde) dropwise into a reactor containing 0.25 mol of hexamethylenediamine, and react at 30° C. for 2 hours. Raise the temperature to 160°C, react for 3 hours, cool down to 90°C, and distill under reduced pressure (at a pressure of 0.07-0.95MPa) for 1.5 hours to obtain Intermediate 2.

[0042] (3) Mix 6.0 g of polypropylene grafted maleic anhydride and 30 g of intermediate 2 in 110 ml of xylene, heat up to 120° C., react for 6.5 hours, remove excess in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com