Method for preparing large-size layered orthorhombic MoS2 nano-film of asymmetric structure under hydrothermal condition

An asymmetric structure, nano-film technology, applied in the preparation of nano-composite materials, micro-field, can solve the problems of difficult to obtain large size, poor repeatability and controllability, and cumbersome process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

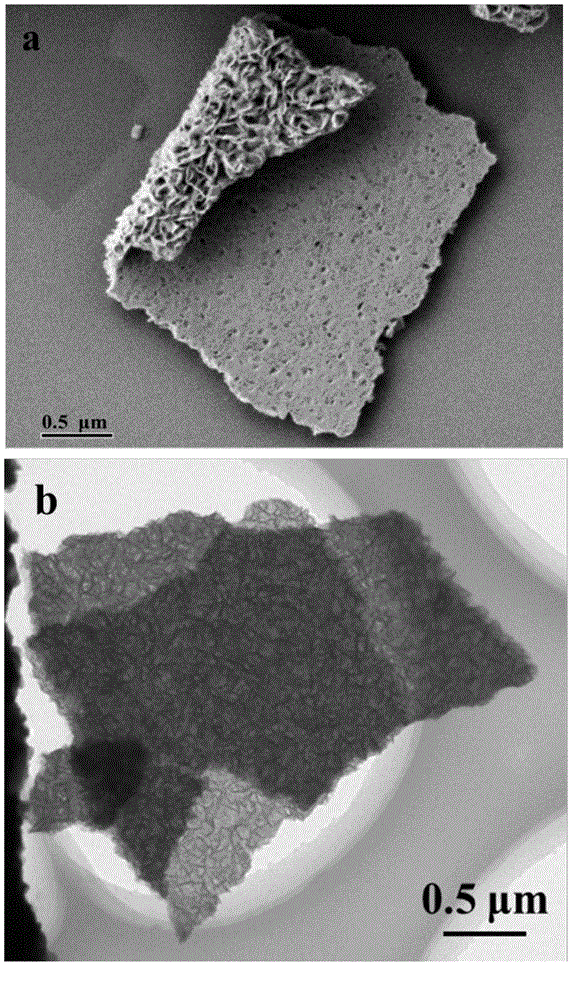

[0034] Weigh a certain amount of molybdic acid, dissolve it with ammonia water to obtain ammonium molybdate, evaporate to dryness in a water bath at 50°C to remove excess ammonia, and then dissolve it with a small amount of deionized water to a concentration of 0.01M. A certain amount of thiourea was weighed and dissolved in NMP as an organic solvent with a concentration of 0.03M. Then mix the aqueous solution of ammonium molybdate and the NMP solution of thiourea at a ratio of 1:20, transfer it into a 100mL polytetrafluoroethylene reactor, and react at 180°C for 24h. once, and then dried under vacuum at 60°C to obtain MoS 2 Powder. The obtained orthogonal asymmetric structure MoS2 nano film is micron size.

Embodiment 2

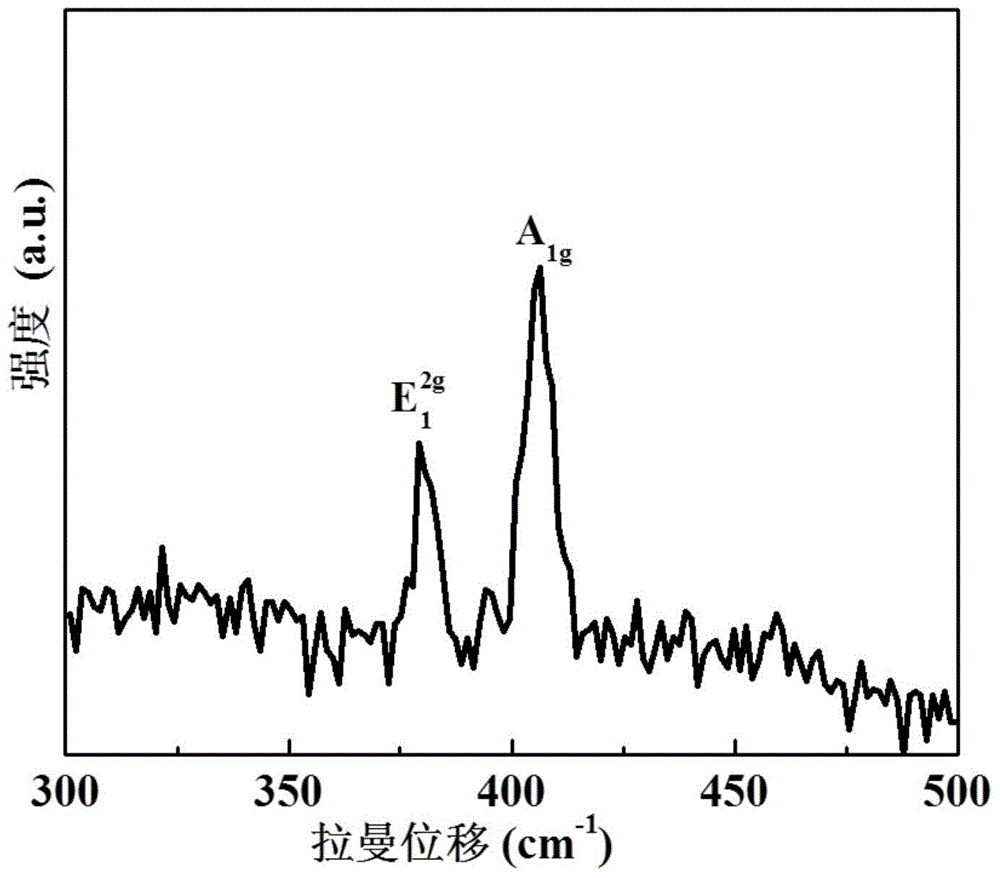

[0036] Weigh a certain amount of molybdic acid, dissolve it with ammonia water to obtain ammonium molybdate, evaporate to dryness in a water bath at 50°C to remove excess ammonia, and then dissolve it with a small amount of deionized water to a concentration of 0.01M. Weigh a certain amount of thiourea, and dissolve it with organic solvent NMP to a concentration of 0.06M. Then mix the aqueous solution of ammonium molybdate and the NMP solution of thiourea at a ratio of 1:20, transfer it into a 100mL polytetrafluoroethylene reaction kettle, and react at 180°C for 24h. ethanol once, and then vacuum dried at 60°C to obtain MoS 2 Powder. In order to improve the crystallinity, the samples were annealed at 800°C for 2h under Ar atmosphere.

Embodiment 3

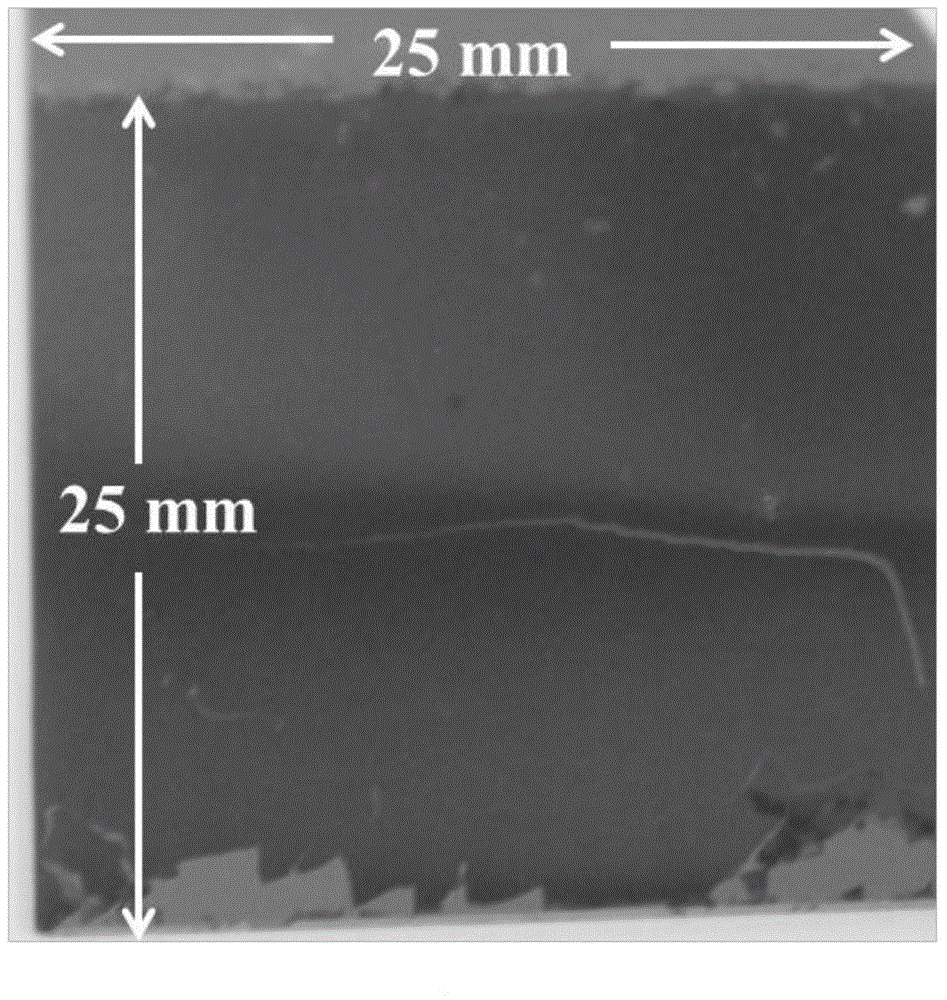

[0038] Weigh a certain amount of molybdic acid, dissolve it with ammonia water to obtain ammonium molybdate, evaporate to dryness in a water bath at 50°C to remove excess ammonia, and then dissolve it with a small amount of deionized water to a concentration of 0.01M. A certain amount of thiourea was weighed and dissolved in NMP as an organic solvent with a concentration of 0.03M. Then mix the aqueous solution of ammonium molybdate and the NMP solution of thiourea at a ratio of 1:20, transfer it into a 100mL polytetrafluoroethylene reactor, and put the cleaned silicon substrate into the reactor at an inclination angle of ~45° (The size is just enough to make it stuck in the kettle, so as to ensure that the substrate does not move during the reaction process), react at 200 ° C for 24 hours, after the reaction, take out the Si sheet, and you can get a wafer-sized orthogonal asymmetric structure two-dimensional layered MoS 2 Nanofilm (see image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com