Dust removal device and pre-separation device with spark trap and automatic fire extinguishing system

An automatic fire-extinguishing system and technology of fire-extinguishing system, which are applied in the field of spark capture and dust removal pre-separation devices, can solve problems such as easy to cause fire, and achieve the effects of strong promotion value, improved effect, and convenient and quick transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

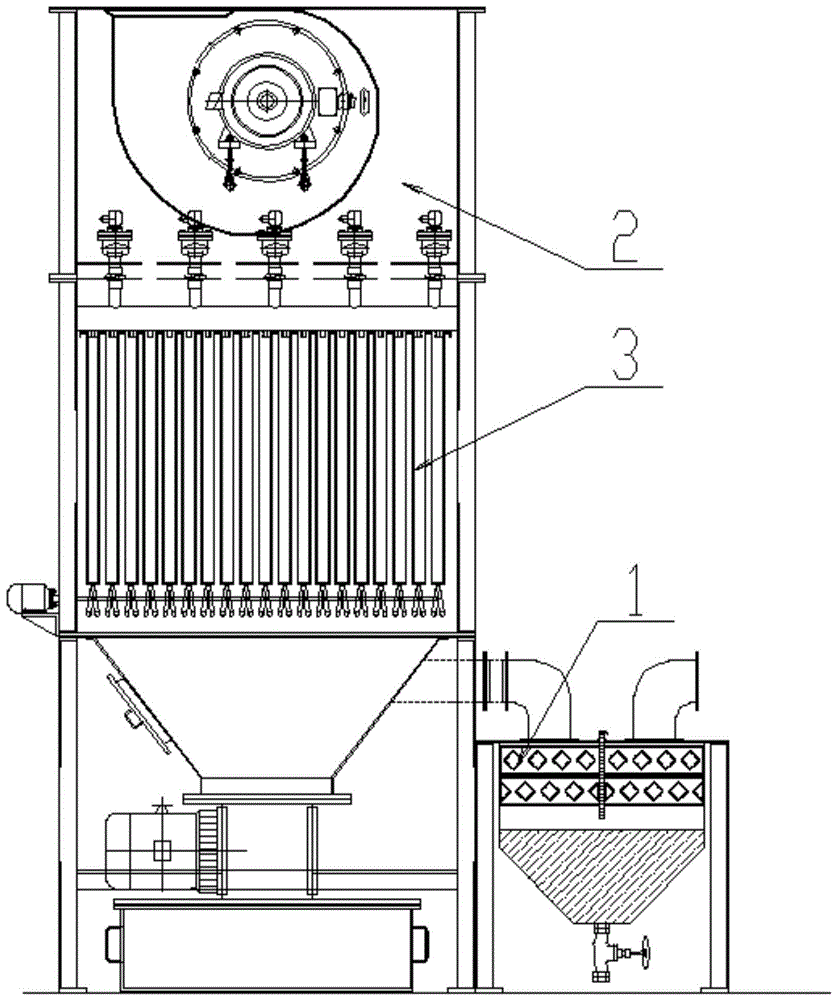

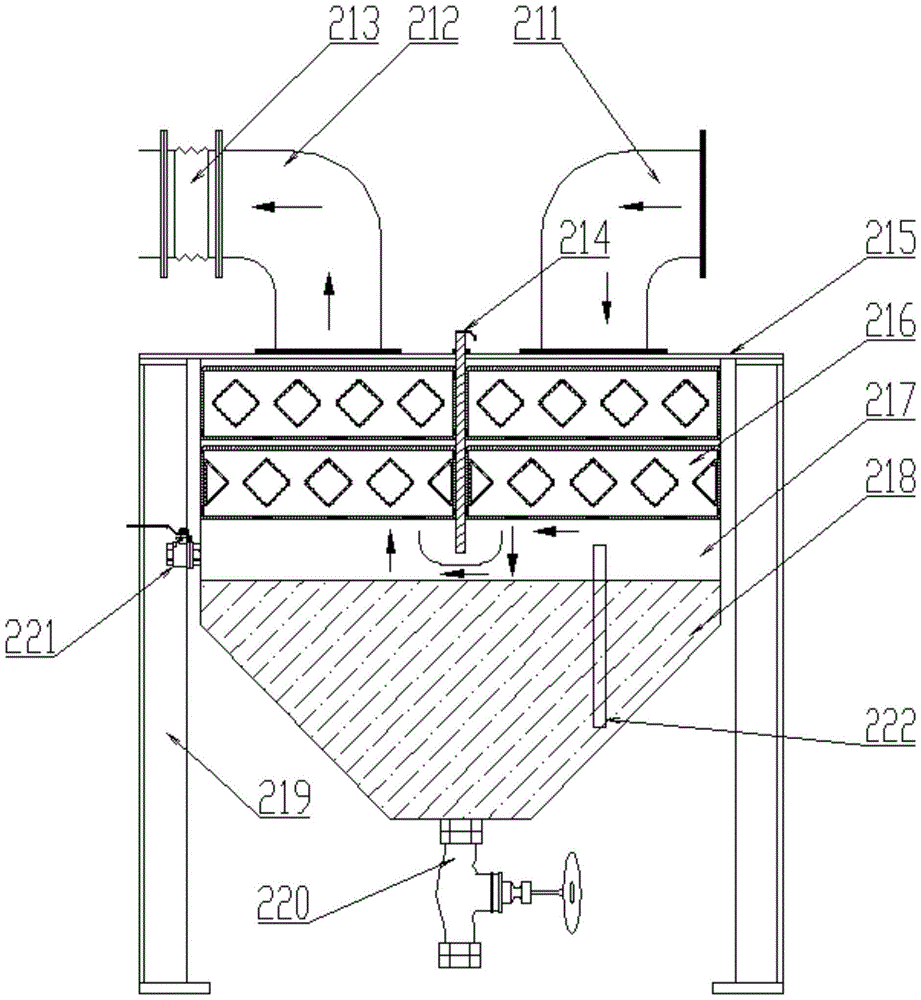

[0043] Such as figure 1 As shown, a dust removal device with a spark catcher and an automatic fire extinguishing system includes a dust collection and dust removal system 1, a spark capture and dust removal pre-separation device 2, an automatic detection and fire extinguishing system 3, and the dust collection and dust removal system 1 is used to treat exhaust gas. Dust collection and dust removal; Mars capture and dust removal pre-separation device 2 is used to carry out spark capture and dust removal pre-separation on the treated waste gas. Through multiple cooling, spark capture and pre-separation, the spark particles in the waste gas are filtered out and the temperature of the treatment air is reduced, thereby Reduce the possibility of fire accidents in the follow-up dust collection and dust removal system 1, reduce the workload of the dust collection and dust remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com