Flexible threshing and pneumatic separating process

A technology of leaf threshing air separation and process, which is applied in the direction of solid separation, separation of solids from solids with airflow, tobacco, etc., can solve the problems of inability to realize continuous production, low equipment utilization rate, poor quality of leaves, etc., and achieve the realization of The effect of flexible production, reducing the difficulty of production organization, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment the invention is specifically described, it is necessary to point out that this embodiment is only used to further illustrate the present invention, but this embodiment should not be interpreted as limiting the protection scope of the present invention, those skilled in the art Some non-essential improvements and adjustments can be made based on the content of the present invention above.

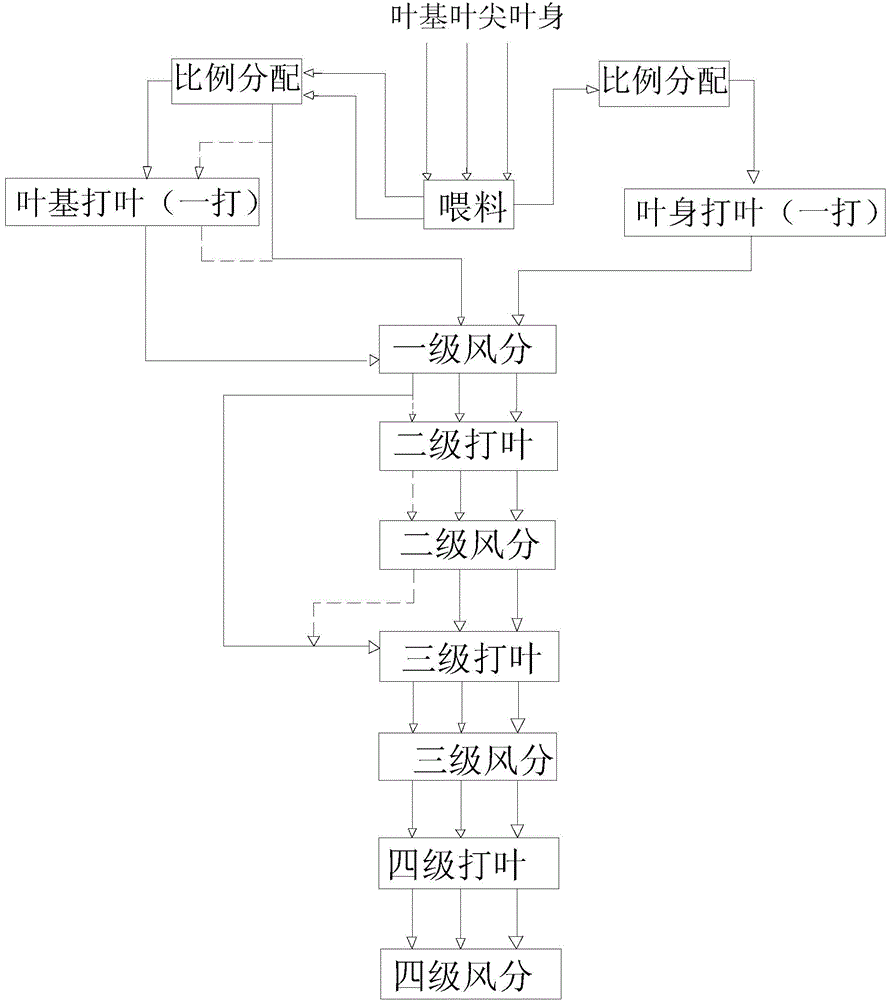

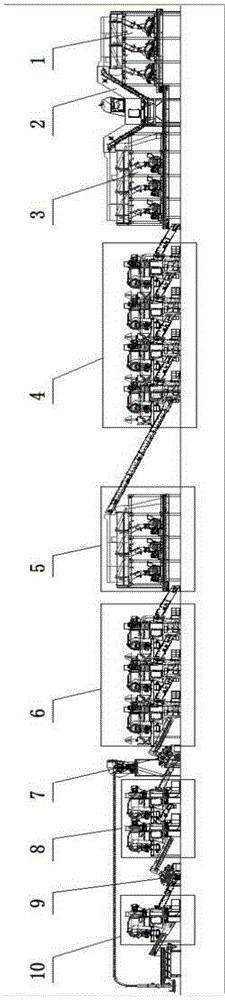

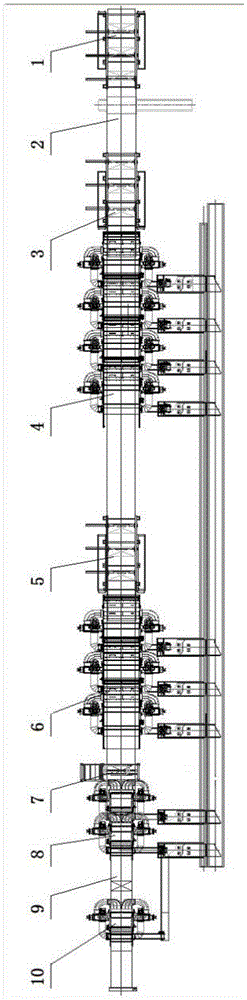

[0017] Such as figure 1 As shown, a flexible leaf threshing and air separation process, including feeding, leaf base threshing, leaf body threshing, first-level wind separation, second-level leaf threshing, second-level wind separation, third-level leaf threshing, and third-level wind separation , four-level threshing, and four-level air separation process, the leaf base threshing is a leaf base threshing, the leaf body threshing is a leaf body threshing, and the feeding process can be selected as leaf base Feed for leaf threshing or leaf body th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com