Pretreatment method of molten iron

A technology of pretreatment and molten iron, applied in the direction of manufacturing converters, etc., can solve the problems of low microwave reflectivity, inability to detect slag level, difficult to measure, etc., to achieve the effect of suppressing bump outflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

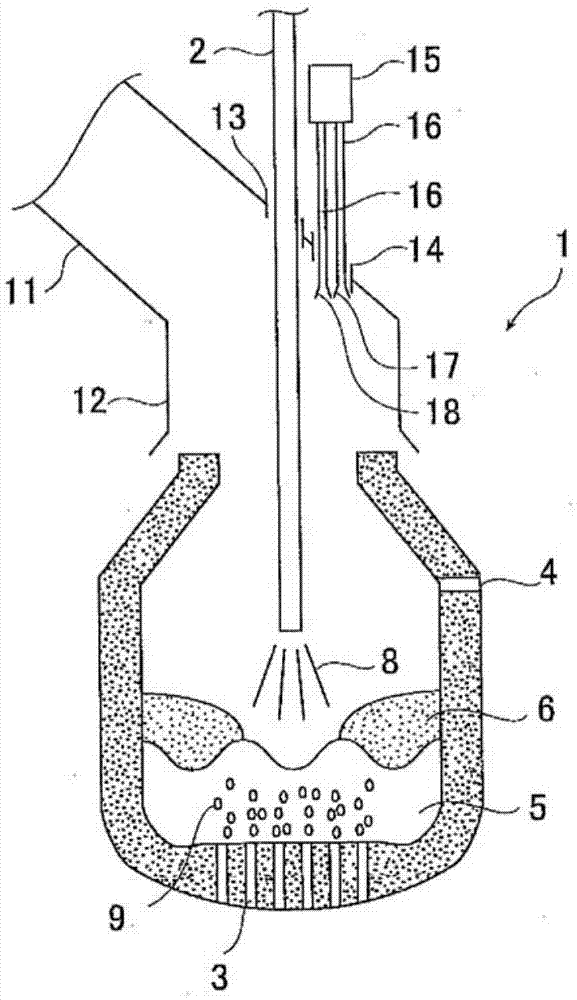

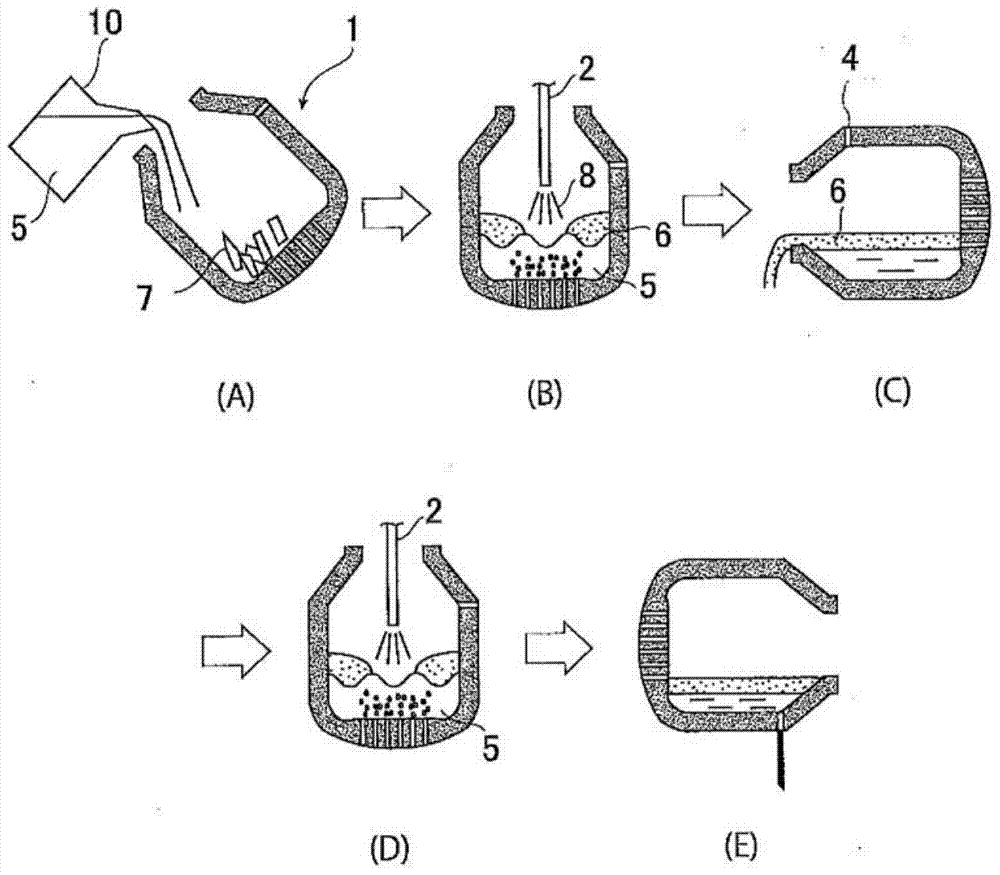

[0125] use figure 1 The shown converter-type refining furnace with a capacity of 330 tons has implemented the molten iron pretreatment of the present invention (Examples 1 to 3 of the present invention) and the molten iron of the conventional method of measuring the slag height through the slag level of the microwave oven but not controlling the slag height Pretreatment (Comparative Example 1, Comparative Example 2) was performed 20 times each. The target value of phosphorus concentration in molten iron at the end of the pretreatment was all set to 0.030% by mass.

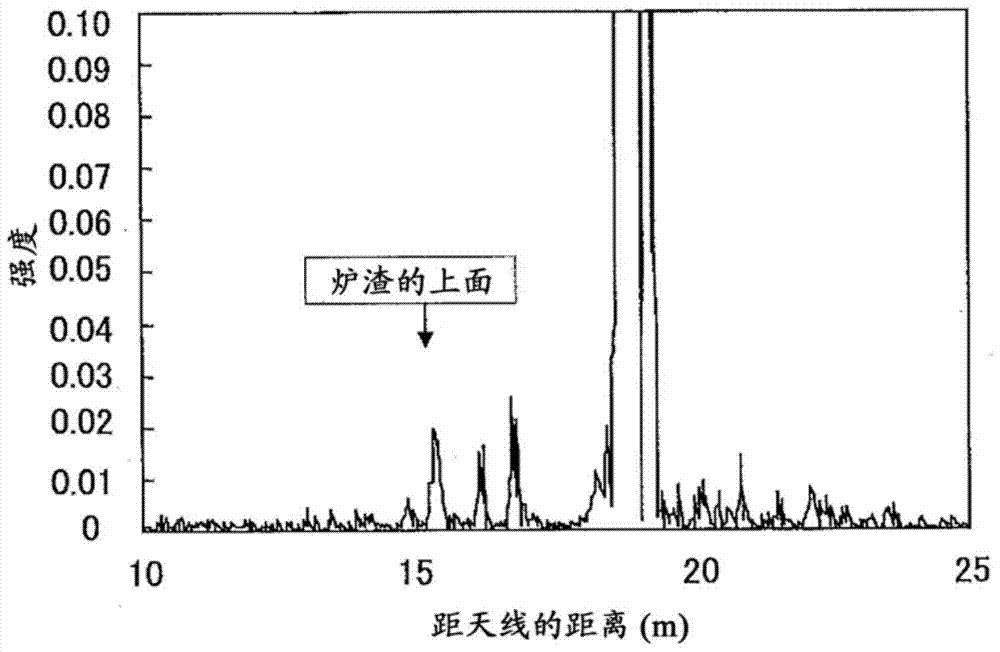

[0126] In Example 1 of the present invention, a microwave oven slag level gauge is used to measure the slag height in oxygen blowing in the desiliconization treatment, and at least one of the oxygen feeding speed from the top blowing lance, the height of the lance, and the gas flow rate for stirring is measured. Adjust the ratio of the measured slag height to the height of the melting chamber in the furnace so tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com