Electronic multi-gear variable-speed motor of electric vehicle and control system thereof

A variable speed motor and control system technology, applied in AC motor control, electric vehicles, control systems, etc., can solve problems such as high cost, heavy weight, and energy loss in gear shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

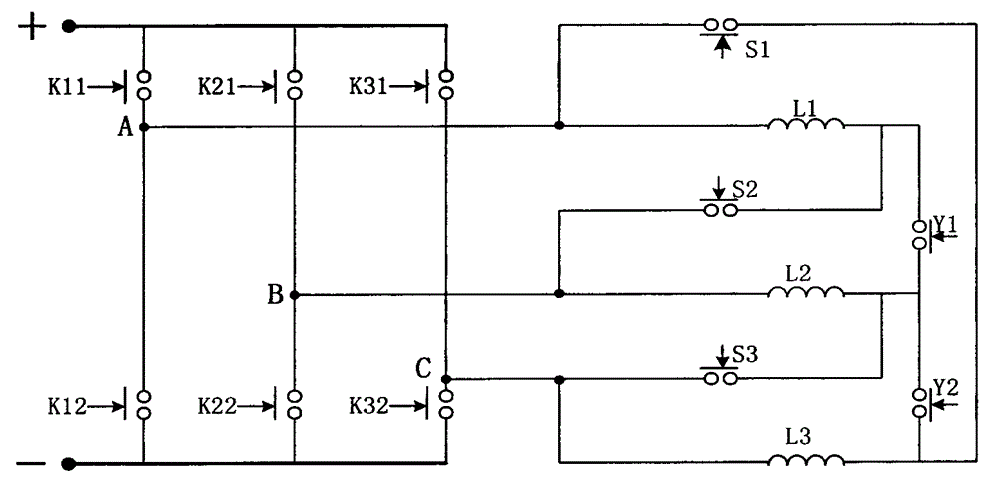

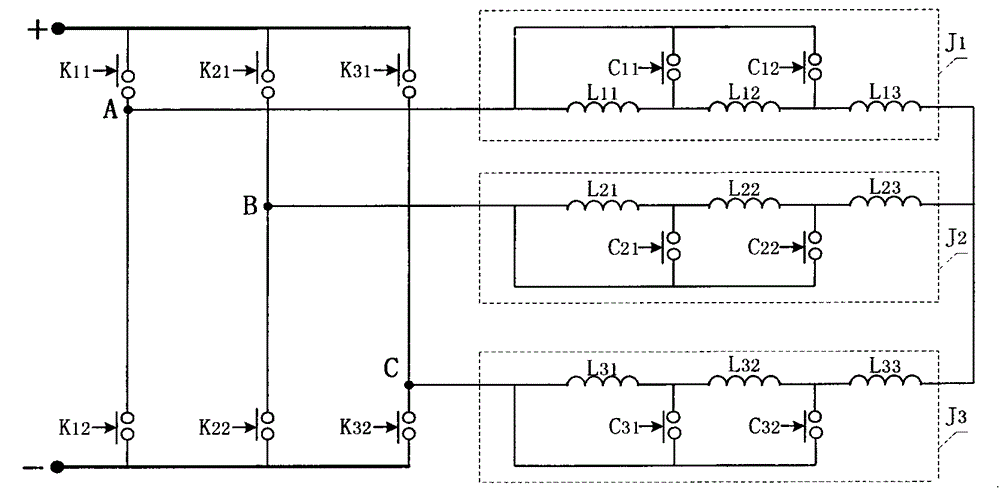

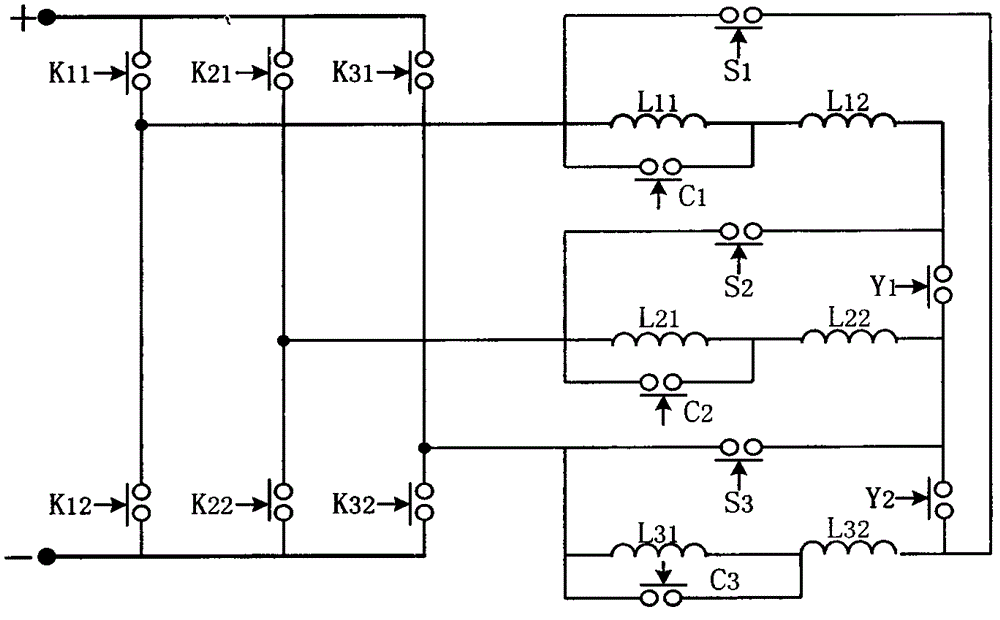

[0046] The electric vehicle and electric vehicle electronic multi-speed variable speed motor and the specific implementation method of the control system are described in detail below. It adopts one or more parallel field effect transistors or IGBT tubes to control three-phase, six-phase, star, delta, Different combinations of hexagonal, series, parallel, single, single-tap and double-tap connections can be switched, and gear shifting can be realized by changing the equivalent impedance of the motor winding. It can form three-phase star connection and delta connection. Switching double-speed variable speed motor and control system, three-phase star connection, double-tap switching three-speed variable speed motor and control system, three-phase star connection, delta connection and single-tap switching four-speed variable speed motor and control system, three-phase Star connection, delta connection, series, parallel and single switching six-speed variable speed motor and contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com