Field-effect transistor and manufacturing method thereof and display

A field-effect transistor and semiconductor technology, which is applied in the direction of transistors, electric solid-state devices, semiconductor devices, etc., can solve the problems of large threshold voltage, unfavorable research and development of field-effect transistors, high energy consumption of field-effect transistors, etc. state voltage, lower threshold voltage, and lower power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the accompanying drawings.

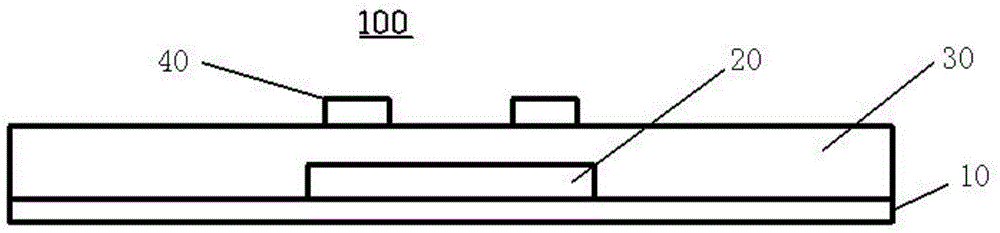

[0028] It should be understood that “upper” and “lower” mentioned here are relative directions. Compared to the semiconductor layer 50 , one side of the first gate layer 20 is the lower side, and the second gate layer 70 is the lower side. One side is the upper side. In addition, the "vertical direction" referred to here is the direction from the first gate electrode layer 20 to the second gate electrode layer 70, or the opposite direction. The "projection along the vertical direction" refers to the projection on the plane where the first gate layer is located, or on a surface parallel to the plane where the first gate layer is located.

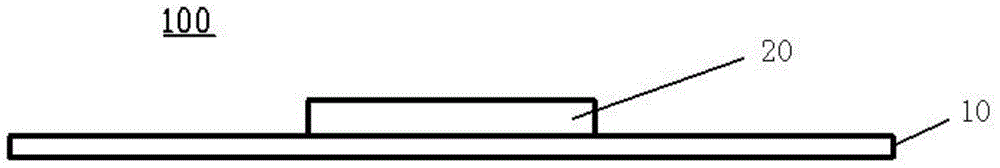

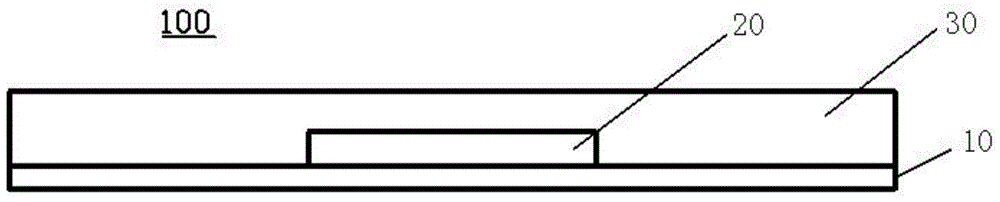

[0029] Figure 1 to Figure 7 The manufacturing process of the field effect transistor 100 of the present invention is schematically shown. The manufacturing method of the field effect transistor 100 is as follows.

[0030] like fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com