ANSYS-APDL (ANSYS parametric design language) development based method for performing transient heat-structure coupling analysis on spherical optical bow cap in complex heat environment

A language development, coupled analysis technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as jitter, offset energy, target image blur, etc., to achieve the effect of dynamic computing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

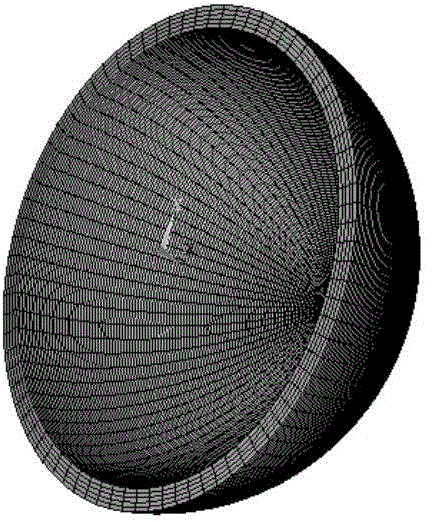

[0041] The invention provides a spherical optical head cover transient thermal-structure coupling analysis method under the complex thermal environment developed based on ANSYS-APDL language, such as Figure 10 And as shown in Table 1, the specific content is introduced as follows:

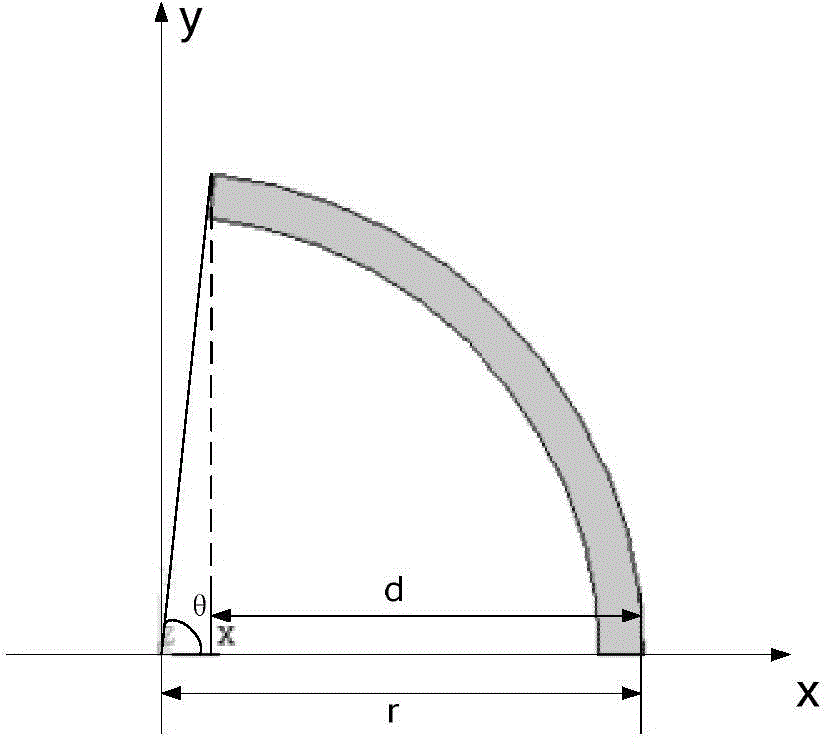

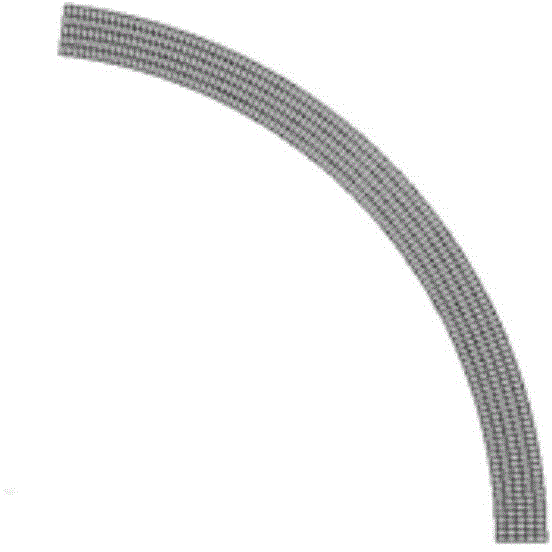

[0042] 1. The establishment of the finite element model of an arbitrary spherical optical headgear based on the APDL language, including the selection of the finite element type, the correct conversion of the size of the headgear in APDL, the control of the grid size and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com