A high-precision surface shape control device for an x-ray band optical element

An optical element and surface shape control technology, applied in the field of X-ray optics, can solve problems such as excessive local surface shape errors, and achieve the effect of simple bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

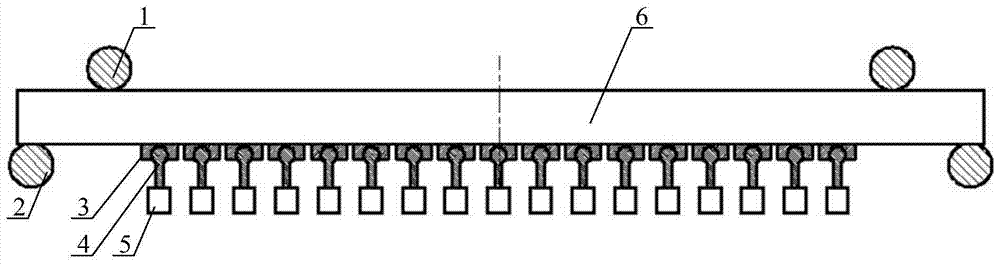

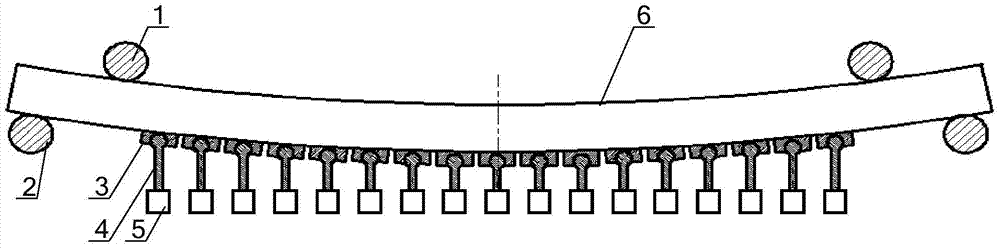

[0018] See attached figure 1 And attached figure 2 , a high-precision surface shape control device for an X-ray band optical element of the present invention includes a driving roller 1, a driven roller 2, an ultra-high-precision displacement control device and a control system;

[0019] The two driving rollers 1 are respectively located above the optical surfaces at both ends of the optical element 6, and the driving roller 1 has three degrees of freedom, including the degree of freedom of rotation along its axis, the degree of freedom along the surface perpendicular to the surface of the optical element 6 and degrees of freedom along the surface of the parallel optical element 6;

[0020] The two driven rollers 2 are respectively located below the bottoms at both ends of the optical element 6, and the driven rollers 2 have one degree of freedom, tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com